Universal-purpose fixing clamp and universal-purpose reamer end method of using the same

A technology for fixing jigs and fixtures, which is used in reaming devices, reaming devices, workpiece clamping devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

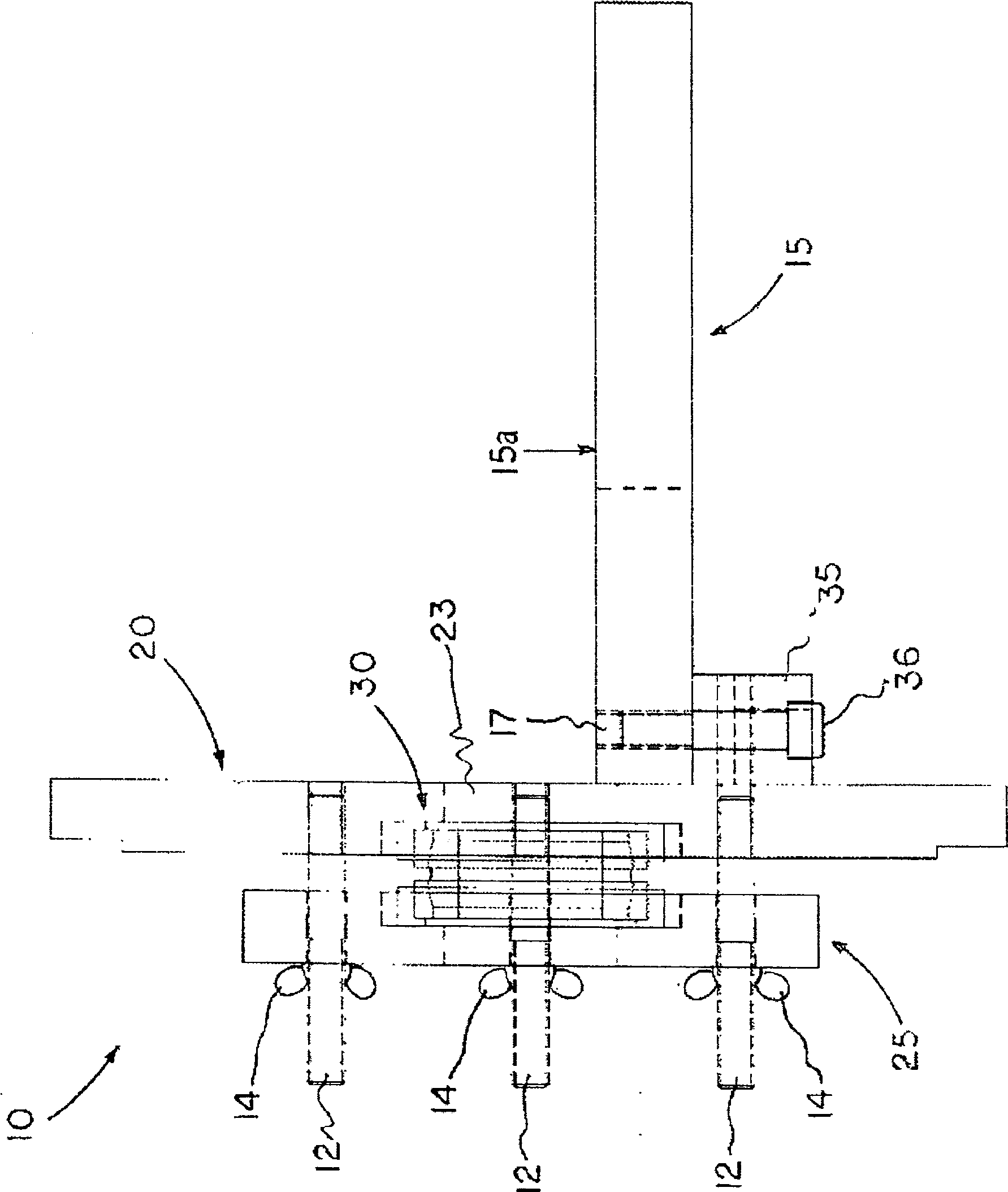

[0021] Such as figure 1 As shown, a universal fixing clamp 10 consistent with the present invention can be seen. For the sake of simplification, the use of the universal fixing fixture 10 in the valve hole reaming operation of the automatic transmission valve body will be mainly introduced here. However, it should be understood that the universal fixture 10, 10' described herein may also be used in reaming valve holes of a transmission oil pump (not shown) or other similar workpieces containing valves.

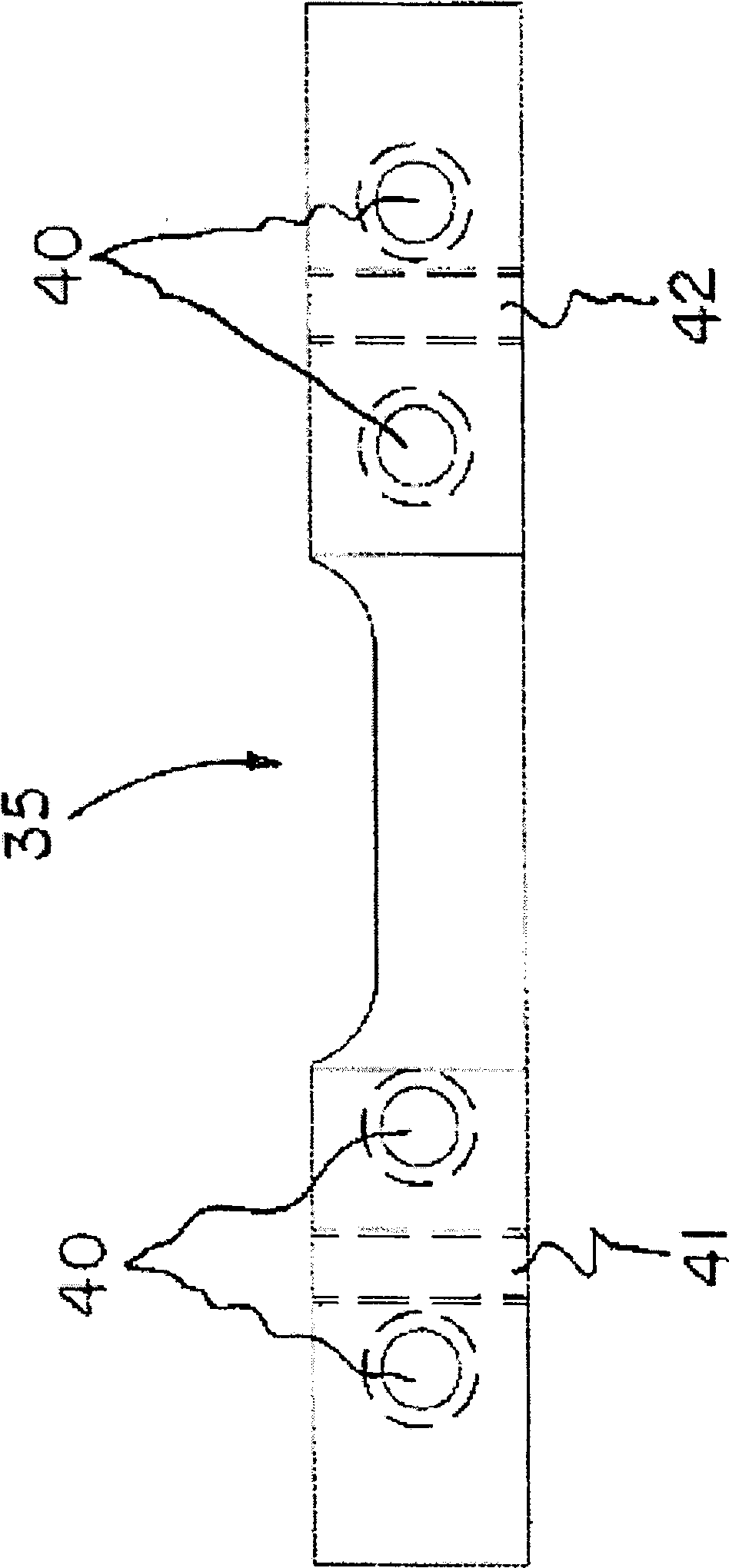

[0022] The universal fixing fixture 10 is an assembly of multiple parts, that is to say, it consists of a base plate 15, a fixture fixing plate 20, a detachable chuck (hereinafter referred to as "chuck") 25 and a tool holder (also known as Formed for "knife holder assembly") 30. exist figure 1 In the device, the mounting bracket 35 fixes the bottom plate 15 and the clamp fixing plate 20, which will be described in detail below.

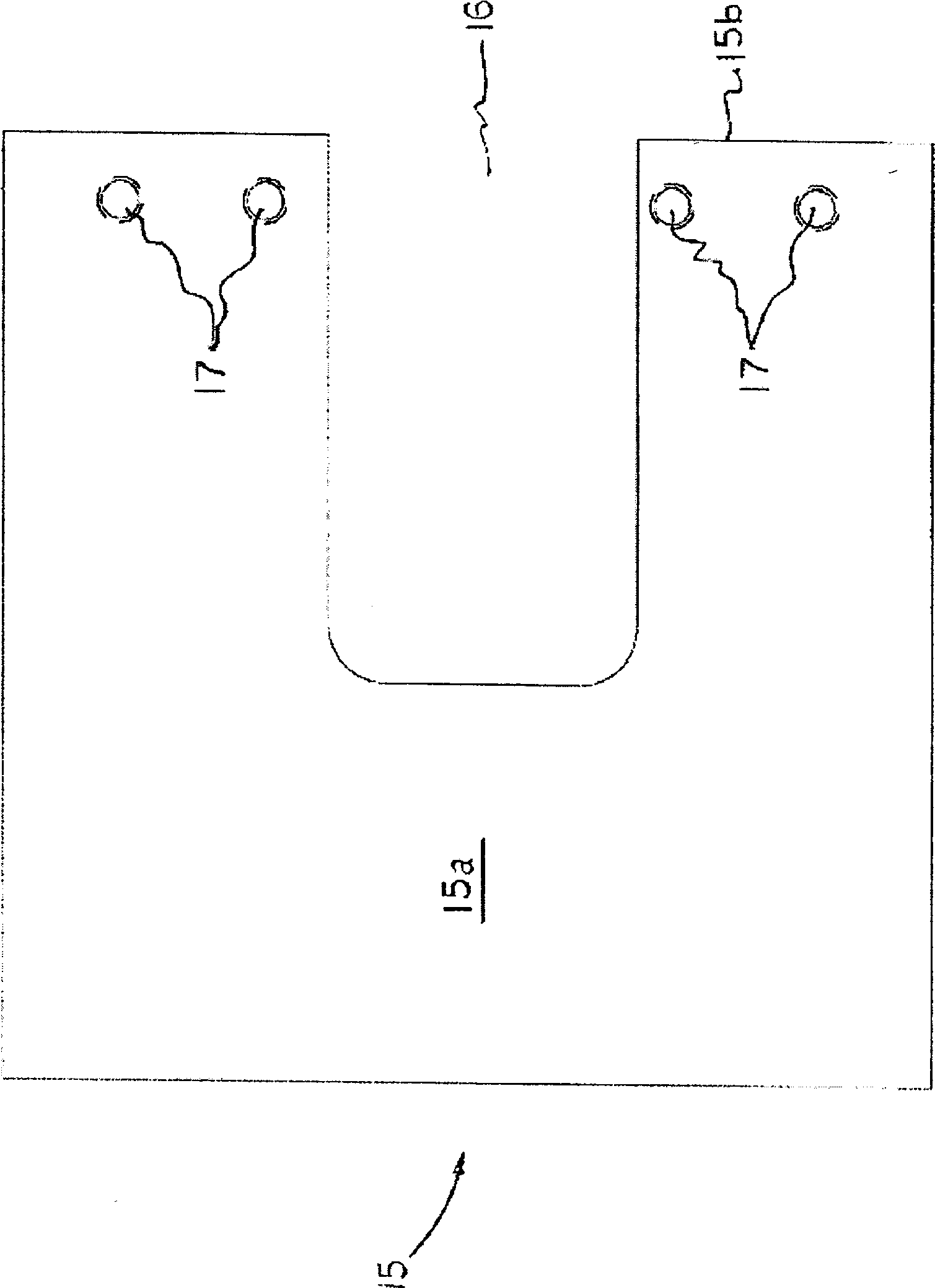

[0023] Such as figure 2 As shown, the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com