Burr scraping device and method for precision machining

A technology of scraping device and precision machinery, which is applied in the field of precision machining, can solve the problems affecting the smoothness and precision quality of the workpiece surface, the problem of adapting the burr scraping device, and low adaptability, so as to improve safety and processing efficiency , Convenient, fast and precise position installation, fast and high-precision burr scraping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

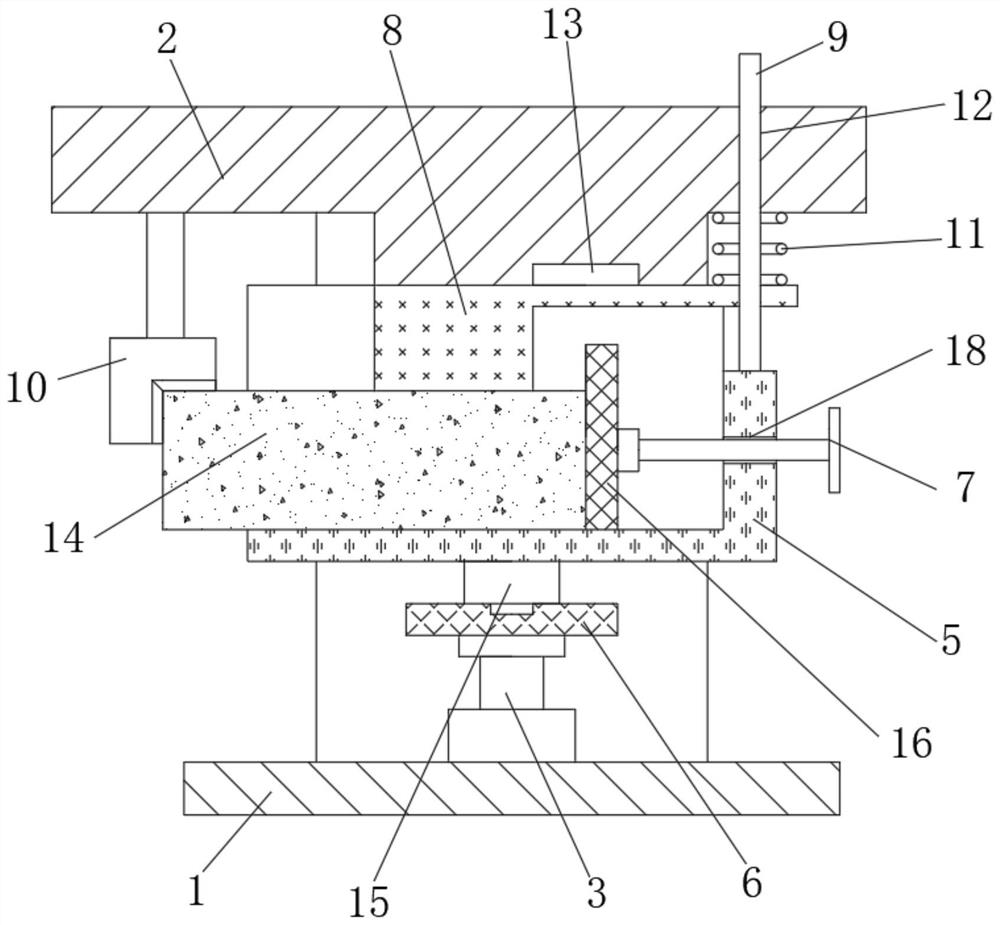

[0046] Embodiment 2: When the workpiece 14 is a drilling cutting surface, the burr is located at the drilling port, and the mounting block 5 is a ring frame, and the positioning of the workpiece 14 is realized by the limit extrusion of the cylindrical positioning block 16 and the fastening cover plate 8. Preliminary fixation, the mounting block 5 is squeezed by the positioning screw 7 to realize the horizontal sliding adjustment of the mounting block 5 on the guide rail 6, so that the burr port is located directly below the scraper 10;

[0047] The lifting column 3 rises to drive the scraping side to fit the scraper 10, and the fastening cover plate 8 presses the spring 11 to realize the fastening and fixing installation of the workpiece 14.

[0048] The driving device 4 adopts a rotating motor with a gear, and the motor drives the gear to mesh with the ring gear 19, so that the mounting block 5 rotates on the upper end of the slider 15, and realizes the circular rotation of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com