Edge banding machine for toy production

A technology for edge banding machines and toys, applied in toys, home appliances, and other home appliances, can solve the problems of inaccurate positioning of edge banding molds, low work efficiency, and complicated mold adjustment work, so as to increase positioning accuracy and improve Work efficiency, increase the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

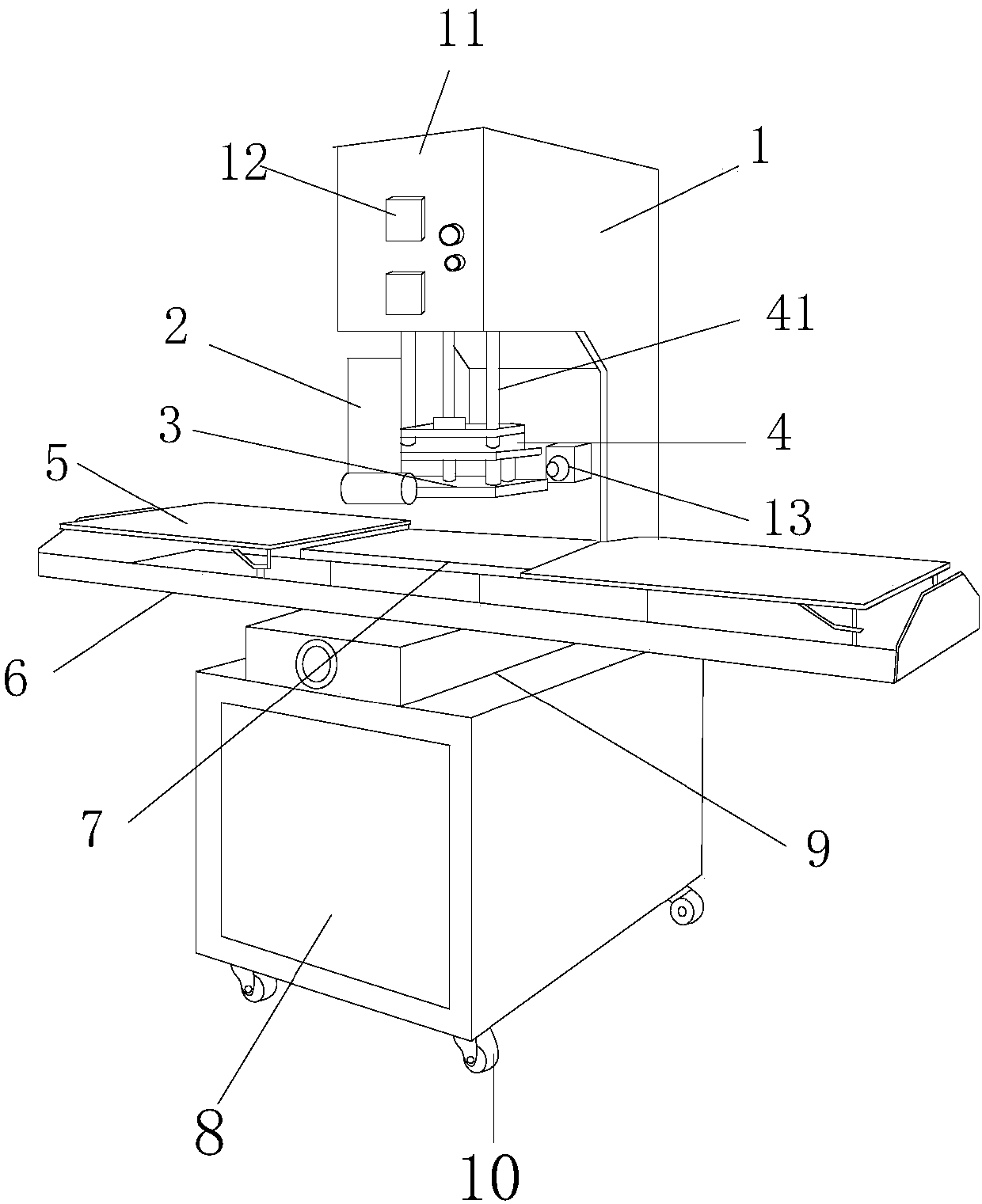

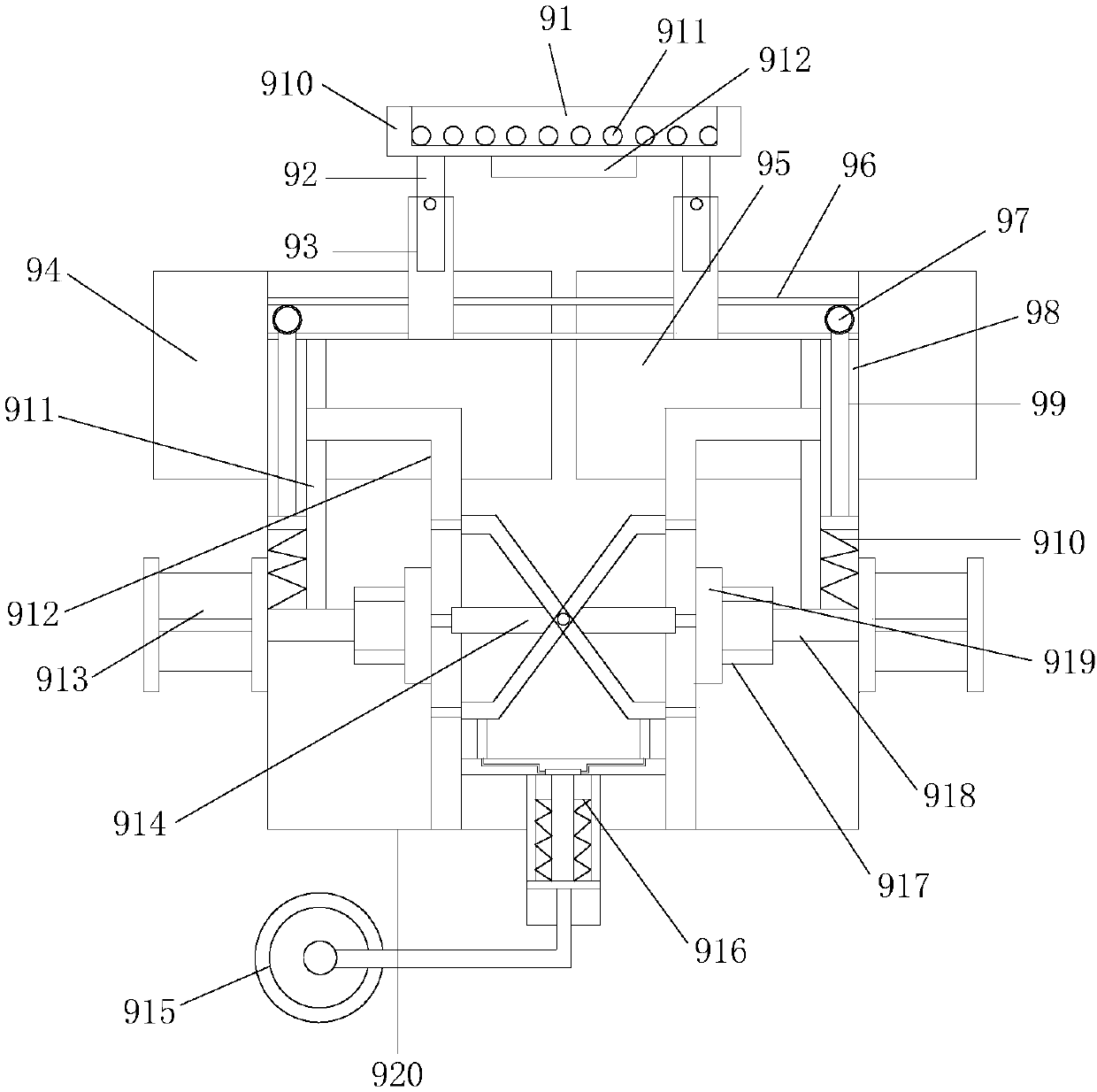

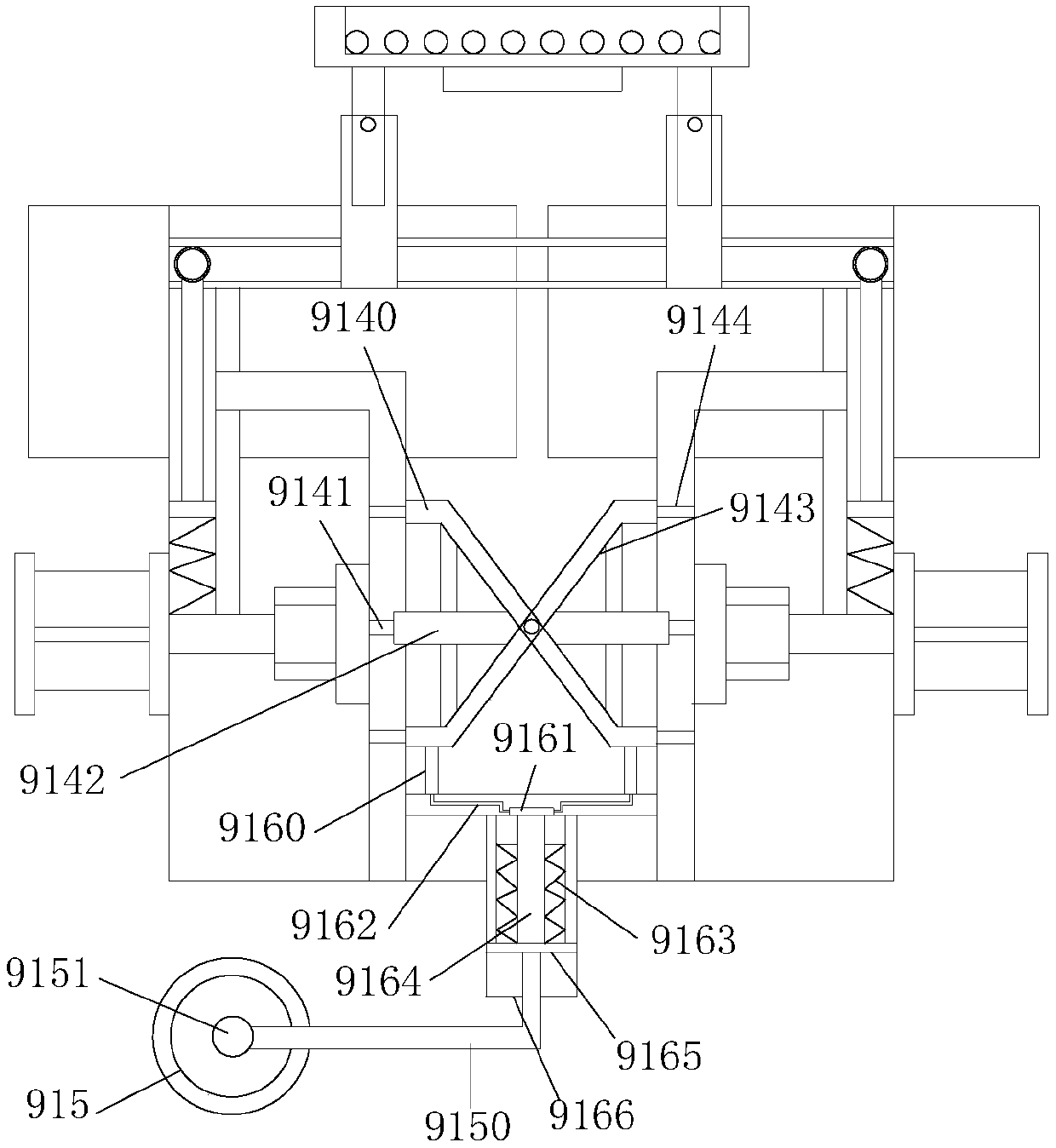

[0023] see Figure 1 to Figure 3, the present invention provides an edge banding machine for toy production, the structure of which includes a power executive seat 1, an edge folding rod 2, an edge banding template 3, a connecting horizontal plate 4, an object conveying backing plate 5, a working platform 6, a positioning sealing Side mold 7, electric control box 8, automatic adjustment and alignment device 9, casters 10, the bottom of the electric control box 8 is movably connected with the casters 10, the tail of the electric control box 8 is fixedly connected with the power executive seat 1 and is perpendicular to each other, The power actuator seat 1 is provided with a control panel 11, an operation switch 12, and an emergency stop key 13. The control panel 11 and the power actuator seat 1 are of an integrated structure, and the operation switch 12 is arranged on the outer layer of the control panel 11. The emergency stop key 13 is embedded in the front end of the power ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com