Method of removing iron from nickel chloride leachate

A technology of nickel chloride and leachate, applied in nickel halide and other directions, can solve the problems of poor effect stability, high fire protection requirements, and many extraction stages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] Heat the chlorinated leaching solution to 85°C, pass chlorine gas into the chlorinated leaching solution, and control the oxidation-reduction potential at 690mv, so that the Fe in the chlorinated leaching solution 2+ Oxidized to Fe 3+ , adjust the pH of the solution to 3.0 with nickel carbonate, stop the addition of nickel carbonate, and form Fe(OH) 3 , reacted for 3.5 hours, and obtained a nickel chloride solution containing less than 0.006 g / l of iron through slag and liquid separation.

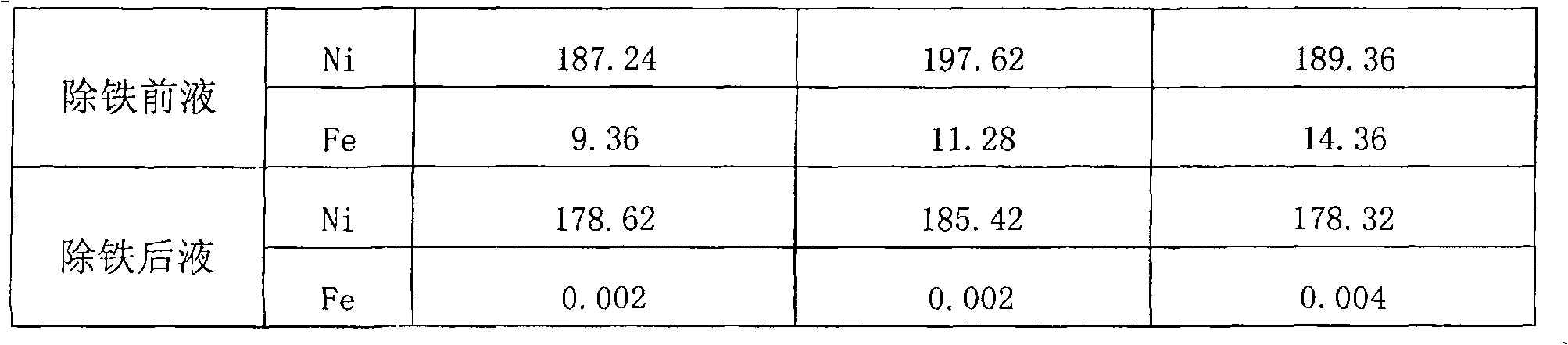

[0010] Statistics of Ni and Fe content in the solution before and after iron removal g / l

[0011]

Embodiment 2

[0013] Heat the chlorinated leaching solution to 90°C, pass chlorine gas into the chlorinated leaching solution, and control the oxidation-reduction potential at 650mv, so that the Fe in the chlorinated leaching solution 2+ Oxidized to Fe 3+ , adjust the pH of the solution to 3.2 with nickel carbonate, stop the addition of nickel carbonate, and form Fe(OH) 3 , reacted for 2 hours, and obtained a nickel chloride solution containing less than 0.006 g / l of iron through slag and liquid separation.

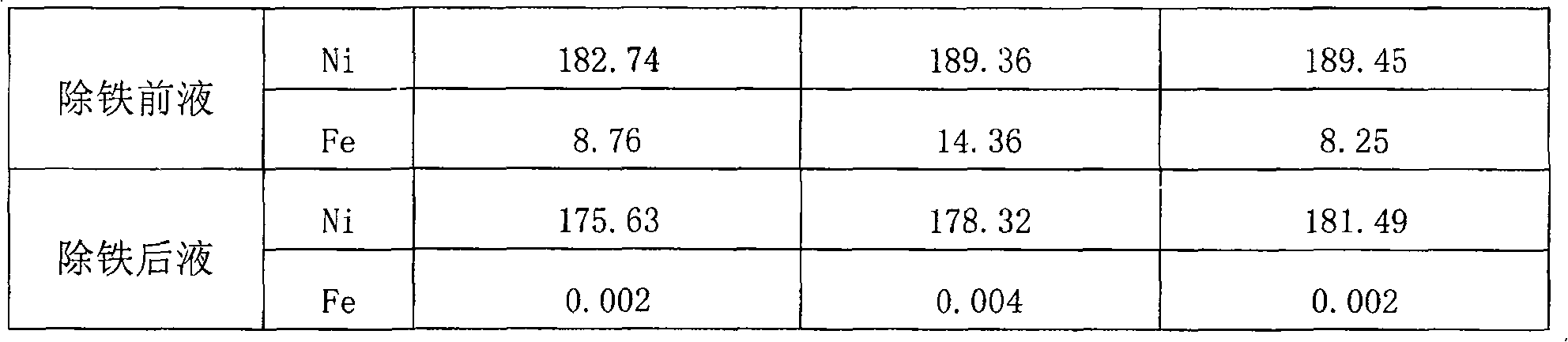

[0014] Statistics of Ni and Fe content in the solution before and after iron removal g / l

[0015]

Embodiment 3

[0017] Heat the chlorinated leaching solution to 88°C, pass chlorine gas into the chlorinated leaching solution, and control the oxidation-reduction potential at 690mv, so that the Fe in the chlorinated leaching solution 2+ Oxidized to Fe 3+ , adjust the pH of the solution to 3.5 with nickel carbonate, stop the addition of nickel carbonate to form Fe(OH) 3 , reacted for 2.8 hours, and obtained a nickel chloride solution containing less than 0.006 g / l of iron through slag and liquid separation.

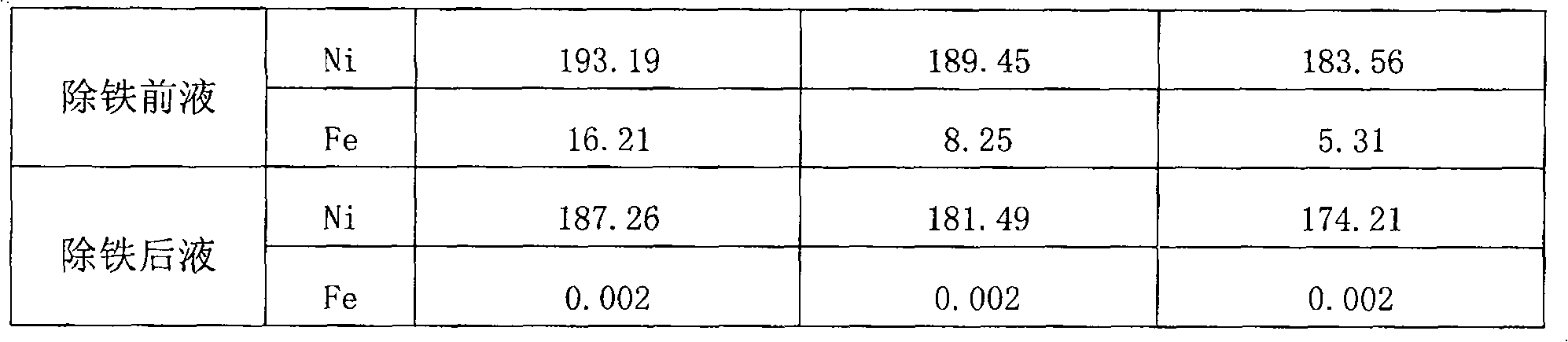

[0018] Statistics of Ni and Fe content in the solution before and after iron removal g / l

[0019]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com