Bulk cargo box with goose neck tunnel

A gooseneck and container technology, applied in the field of large-scale containers, can solve the problems of insufficiency and inconvenient unloading of bulk containers, and achieve the effects of reducing quantity setting, convenient unloading, and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further elaborate the technical means and effects adopted by the present invention to achieve the predetermined purpose, please refer to the following detailed description and accompanying drawings of the present invention. It is believed that the purpose, characteristics and characteristics of the present invention should be able to gain a deep and specific understanding from this , however, the accompanying drawings are provided for reference and illustration only, and are not intended to limit the present invention.

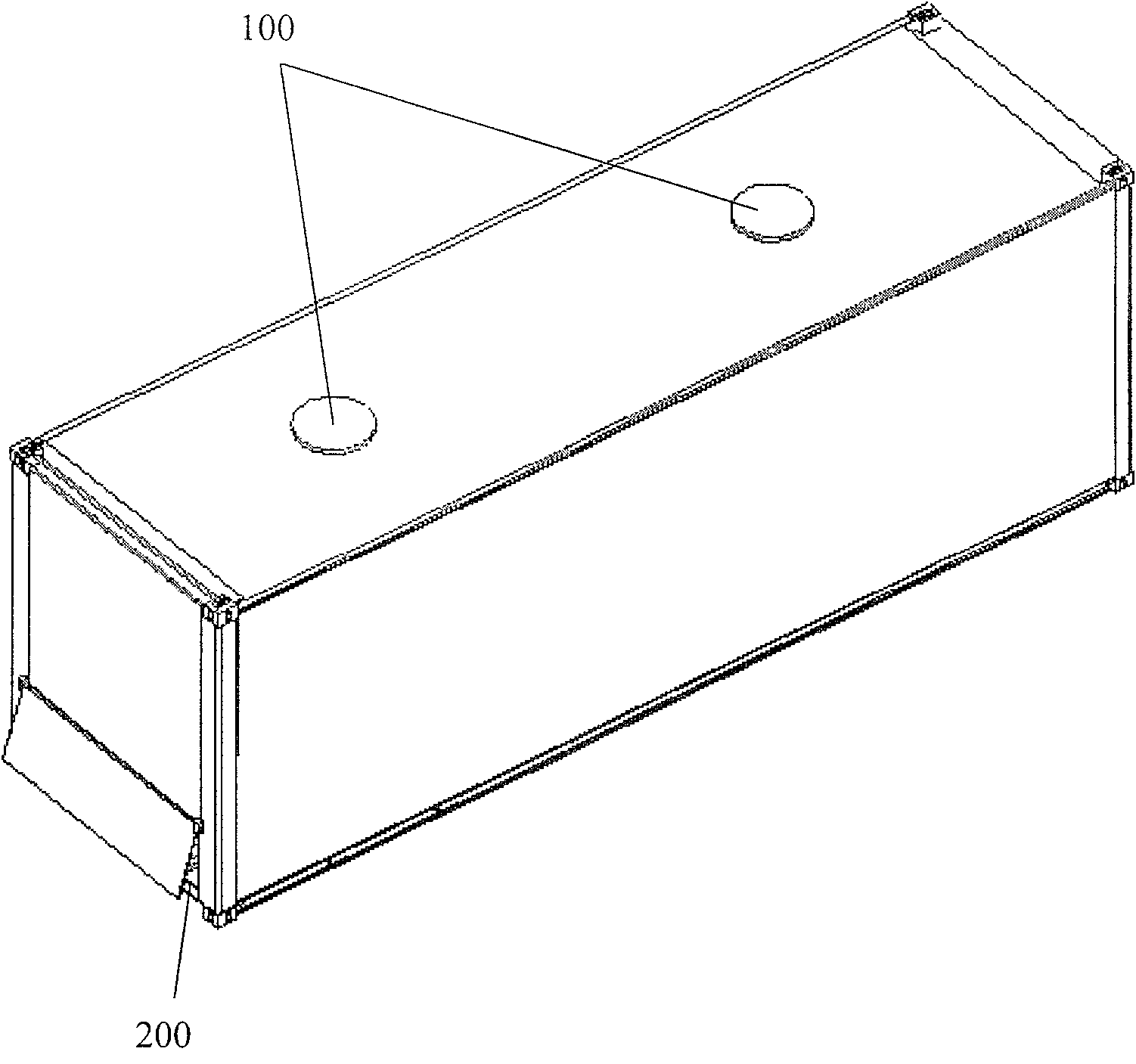

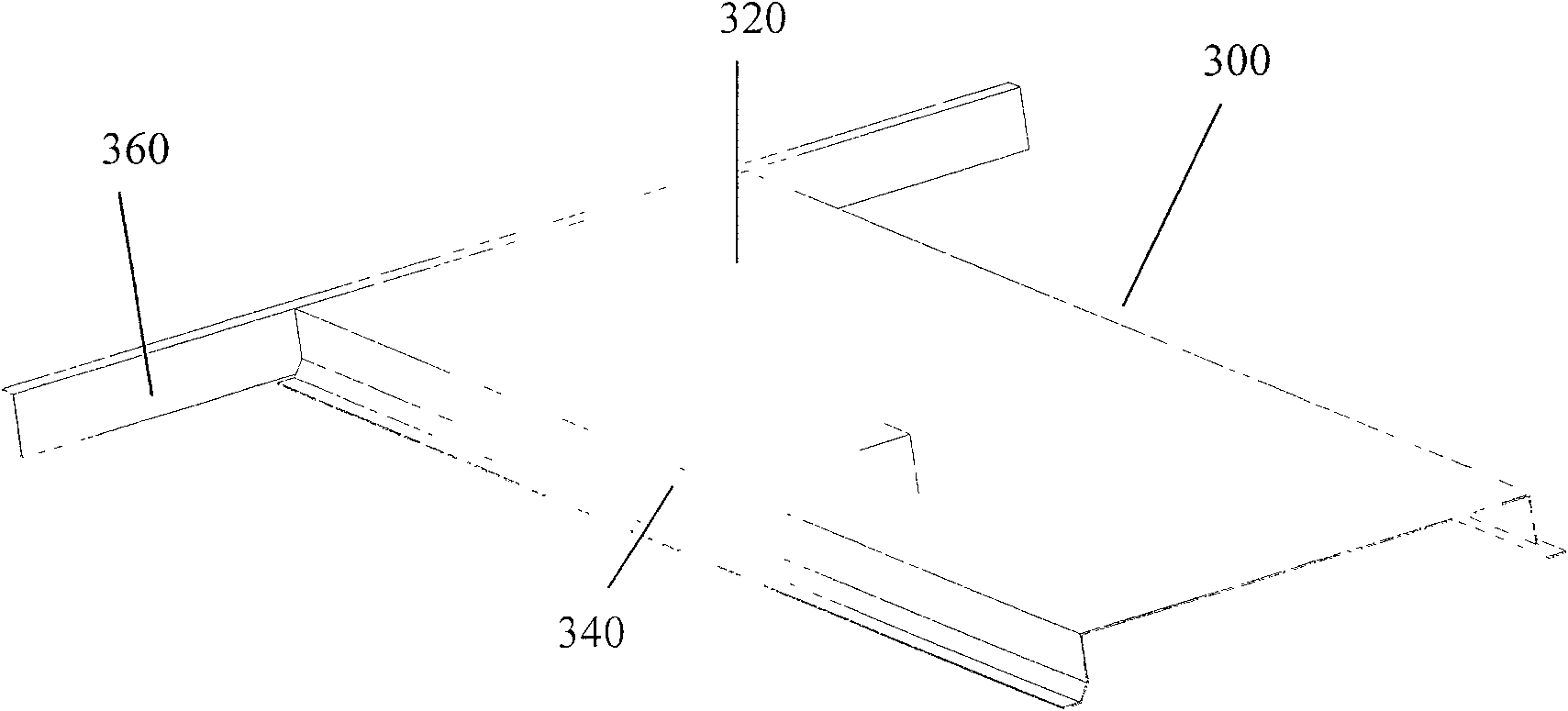

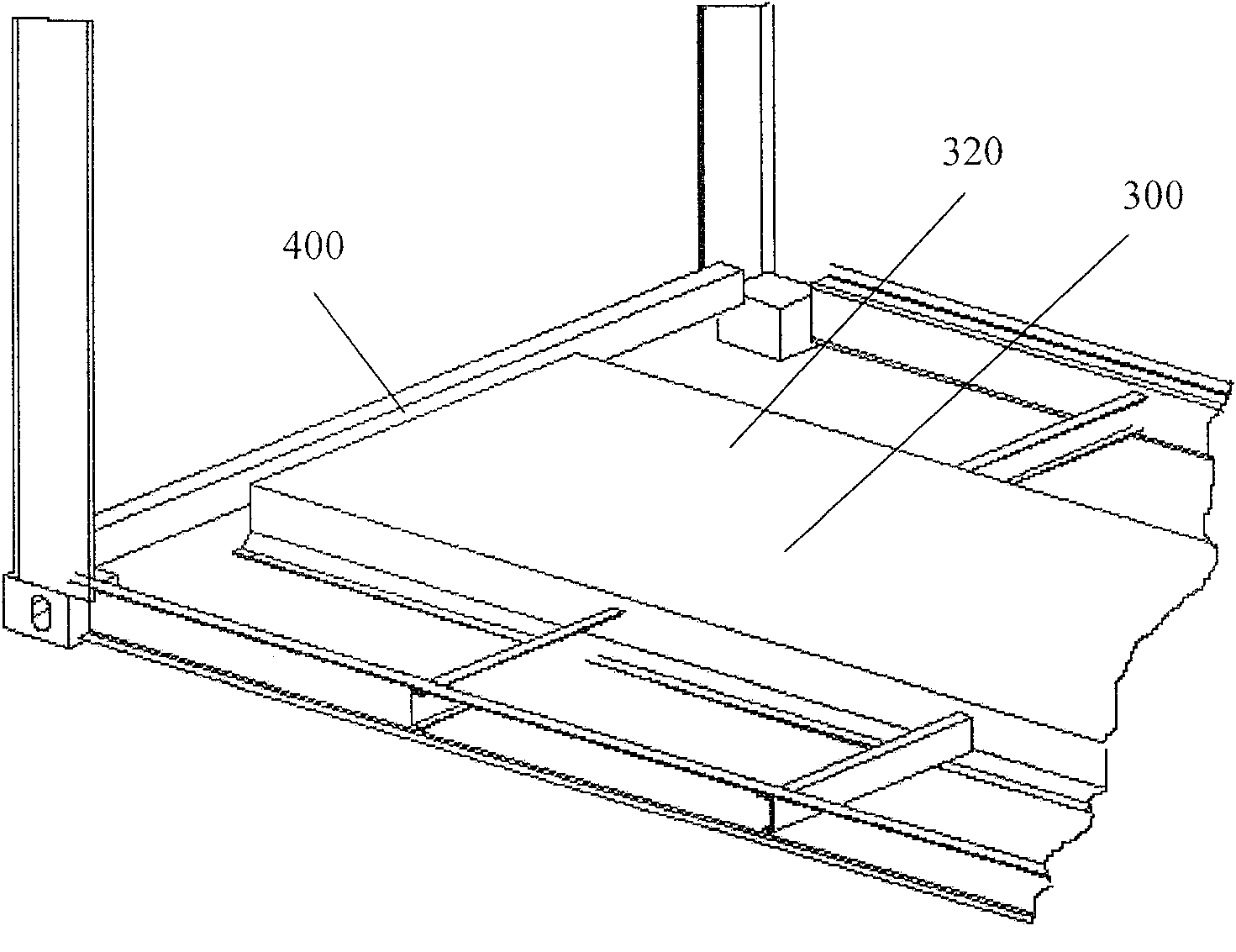

[0025] Such as Figure 5 As shown, the bulk container with a gooseneck groove of the present invention includes an underframe 2 at its bottom, a front frame 3 and a rear end frame 4 perpendicular to the front end and rear end of the underframe 2 respectively, and a material inlet arranged at its top 5 and the outlet 6 arranged at the bottom of the front frame 3, the bottom of the front frame 3 is provided with a front lower beam 32, the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com