Electricity-free holding contactor

A technology of maintaining contact and contactor, applied in the direction of non-polar relays, etc., can solve the problem of restricting the use of non-electrical maintaining contactor, etc., and achieve the effect of simple structure, easy implementation and effective disconnection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

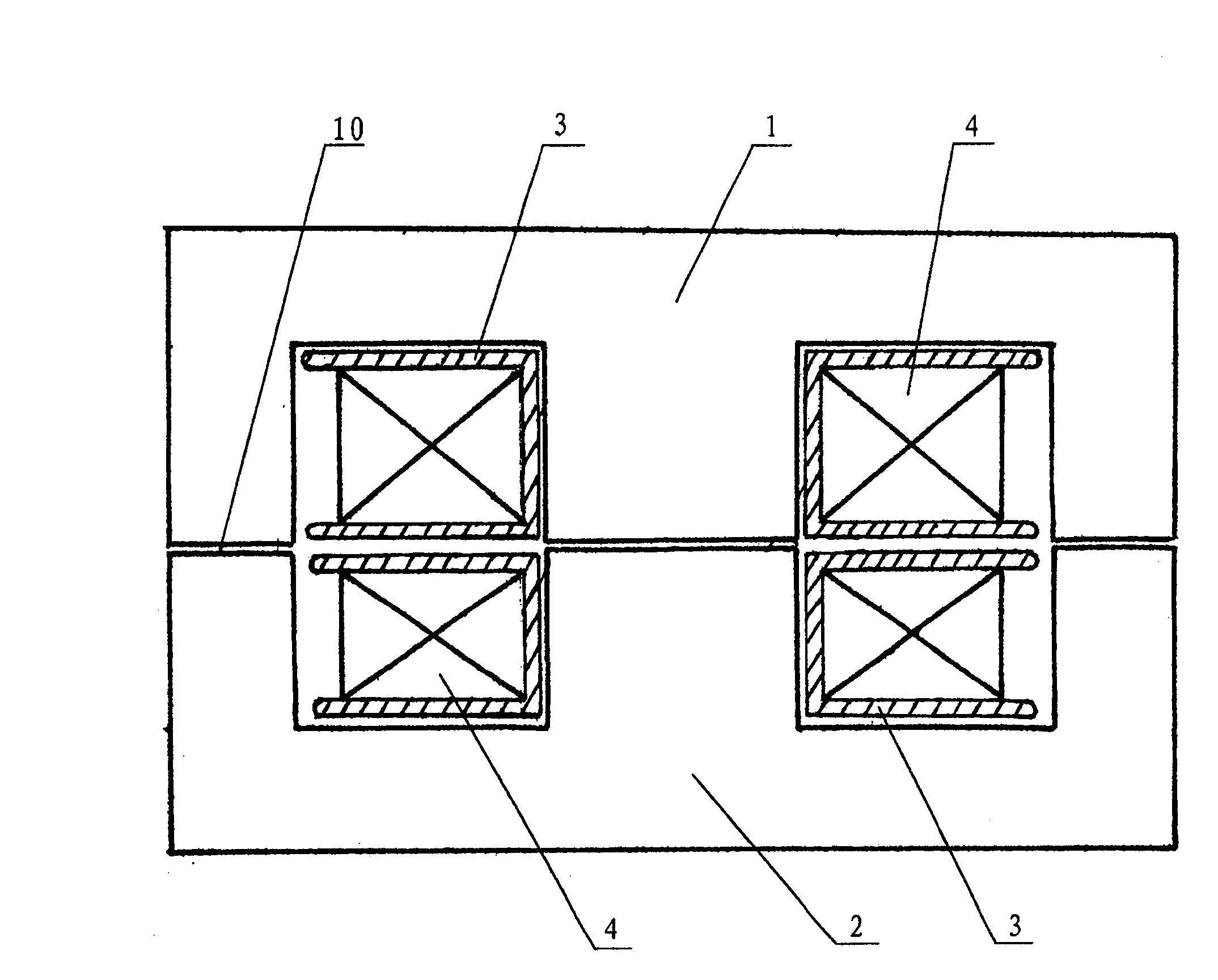

[0014] Such as figure 1 As shown, the iron absorber of the non-electric holding contactor is composed of a moving iron core 1 and a static iron core 2. The coil support 3 arranged around the core column of the iron absorber is two sections separated from each other, and the two coil supports are respectively located on the moving iron core. The core and the core column periphery of the static iron core, the electromagnetic coil 4 is also divided into two groups, which are respectively wound on two sections of coil supports. In this way, when the current in the same direction is passed through the two sets of coils, the moving iron core and the static iron core are attracted; and when the reverse current is passed through the two sets of coils, the moving iron core and the static iron core can be repelled.

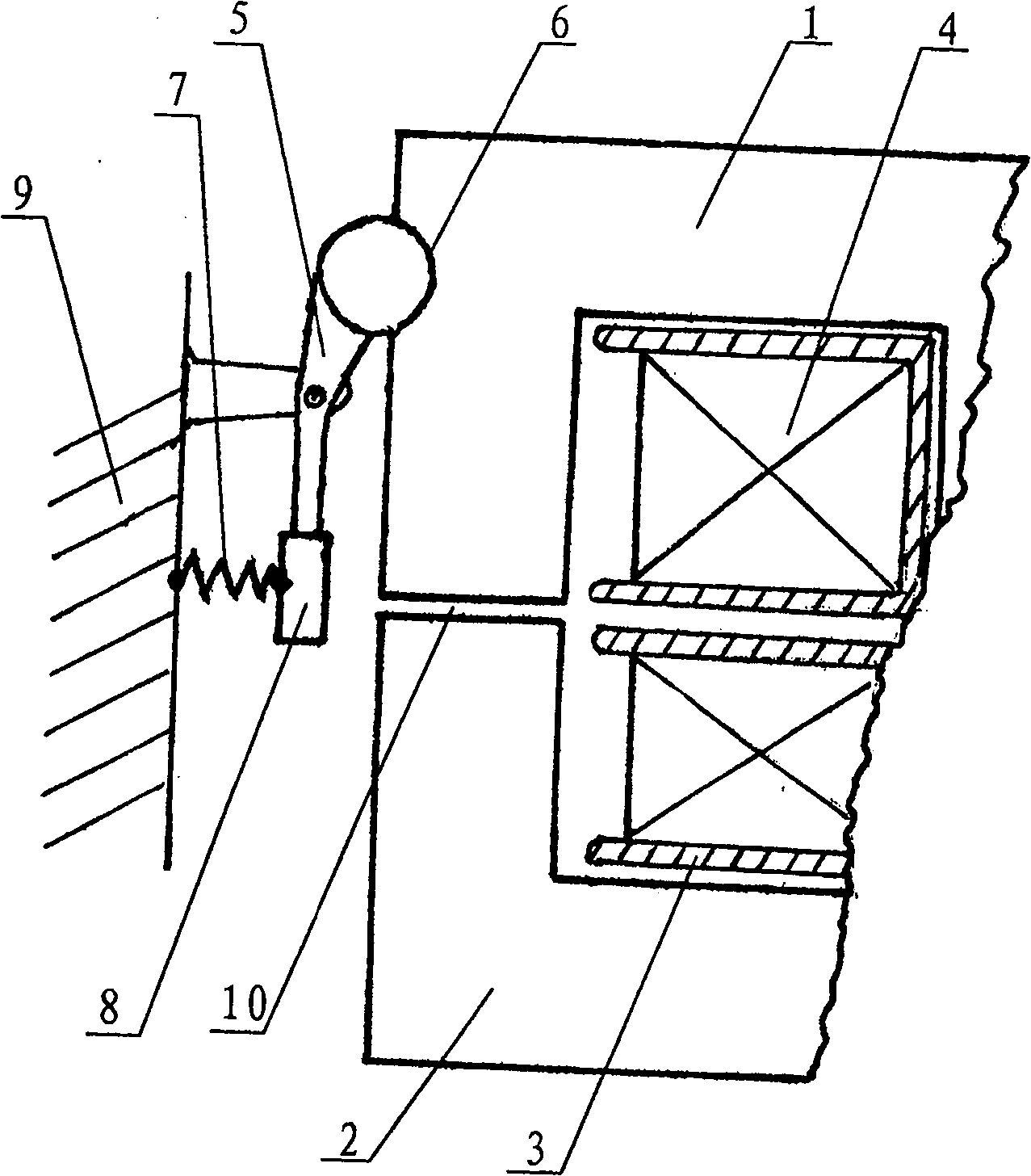

[0015] exist figure 2 In the shown embodiment, a latch 5 with a lever structure is hinged on the housing 9 of the contactor. The middle part of the latch is a hinge shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com