Online material calibration apparatus for belt scales

A belt scale and standard measurement technology, applied in the field of the belt scale online physical verification device, can solve the problems of wasting resources, laborious, time-consuming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

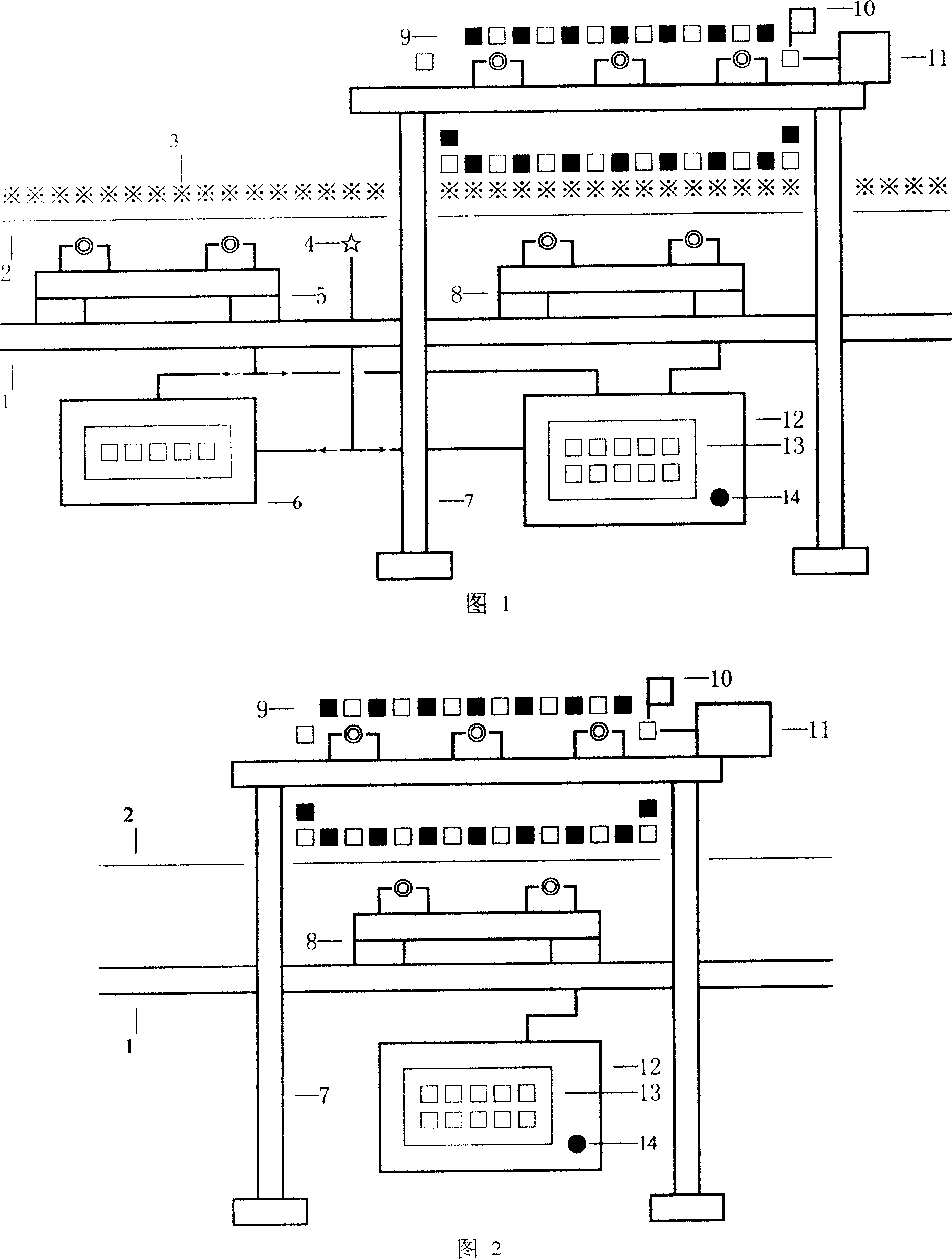

[0023] The purpose of the present invention is achieved in this way: the new calibration device, by setting the standard measuring frame and the weighing frame of the belt scale to detect the weight of the material to be transported synchronously, to obtain two weighing signals of equal size, the calibration is established after the signal is synthesized. The dynamic zero point of the verification system; by setting the standard weight code block ring to impose a standard weight on the standard measuring frame, to carry out standard transfer, and establish the verification standard and basis of the verification system; by setting the signal synthesizer and the instrument display. The signal is synthesized, and the standard value of the calibration data is measured and displayed. The belt scale instrument is adjusted against the standard value of the calibration data to carry out and complete the physical calibration work.

[0024] details as follows:

[0025] Set up a measurem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com