Belt balance for auto verifying true object

A material and weighing rack technology, applied in continuous material flow weighing equipment, weighing equipment testing/calibration, measuring devices, etc., can solve problems such as affecting normal production, low calibration accuracy, and wasting power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

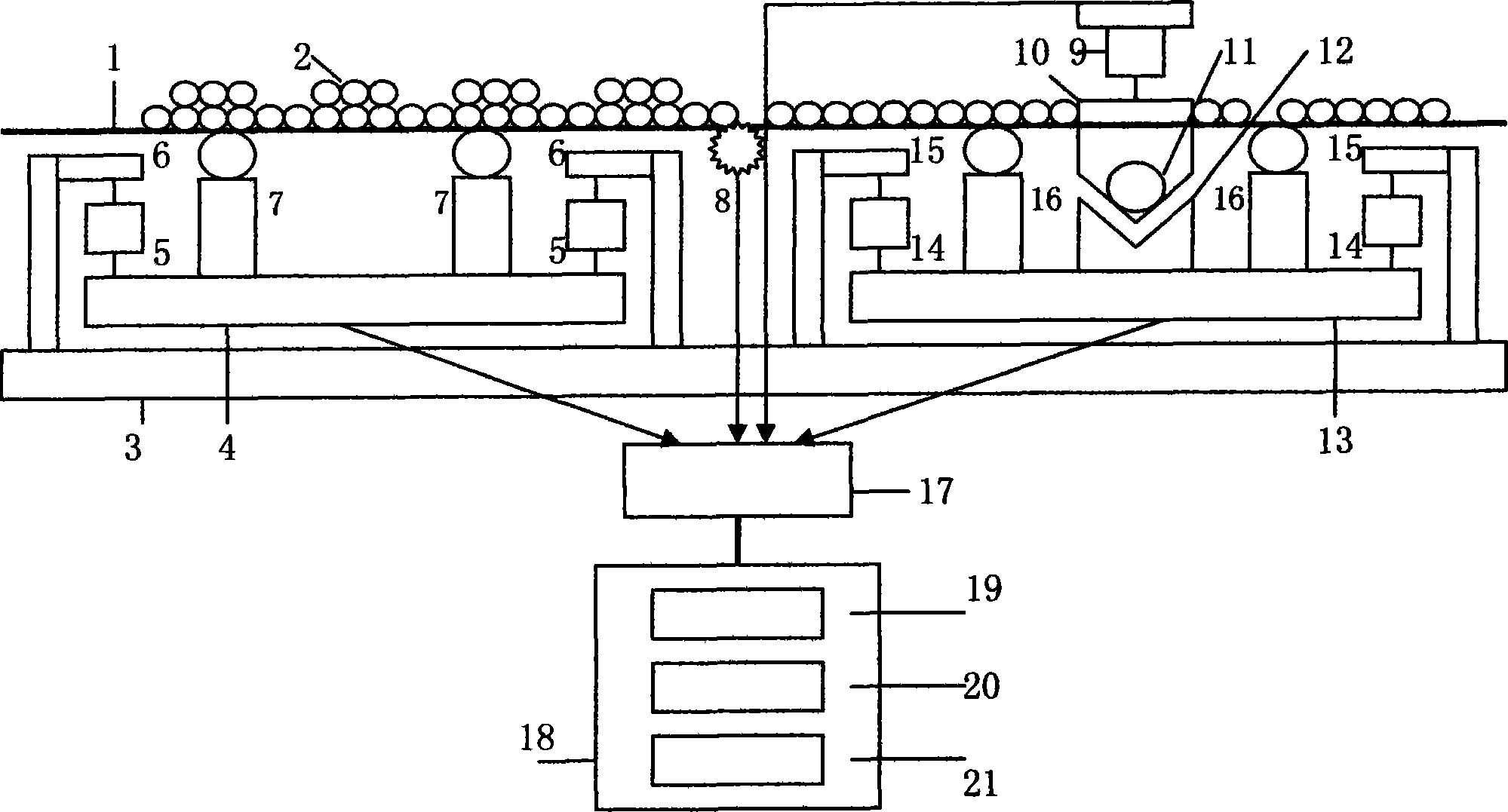

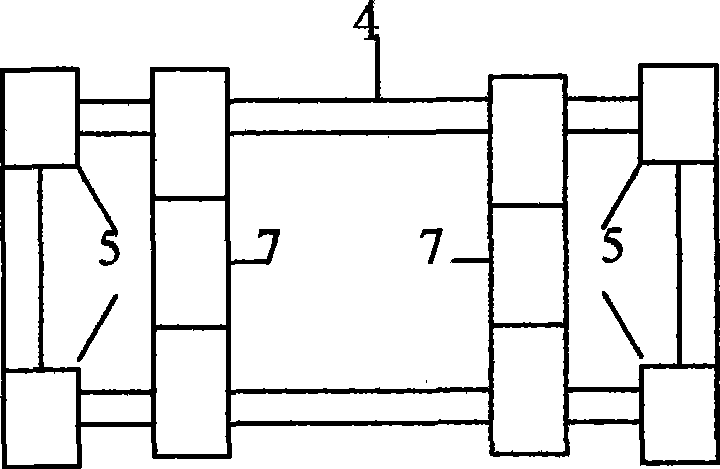

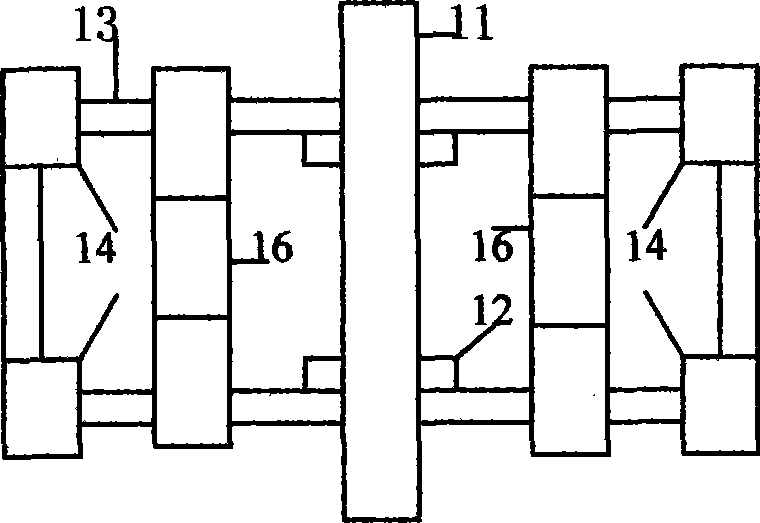

[0032] The object of the present invention is achieved in this way: the belt scale for automatic physical verification can obtain two weighing signals of equal size by setting the main weighing frame and the auxiliary measuring frame to detect the weight of the material transmitted by the belt synchronously. Each weighing signal can be independently output and measured independently, and can be measured by subtraction to form a composite signal; the belt scale instrument measures and displays the flow and cumulative amount of the material transported by the belt by measuring the signal of the main weighing frame; By setting the standard weight and automatic hanging weight device, a standard weight is applied to the secondary measuring frame for standard transfer; the belt scale instrument automatically monitors whether the measurement is inaccurate by measuring whether the weight on the secondary measuring frame meets the standard , and once the measurement is found to be inacc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com