Thread stabilizer

A stabilizer and thread technology, used in the field of fluid pressure measurement and control devices, can solve the problems of mechanical wear and tear of metal materials, can not achieve automatic control, can only swing for a period of time, etc., to reduce mechanical wear, increase service life, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

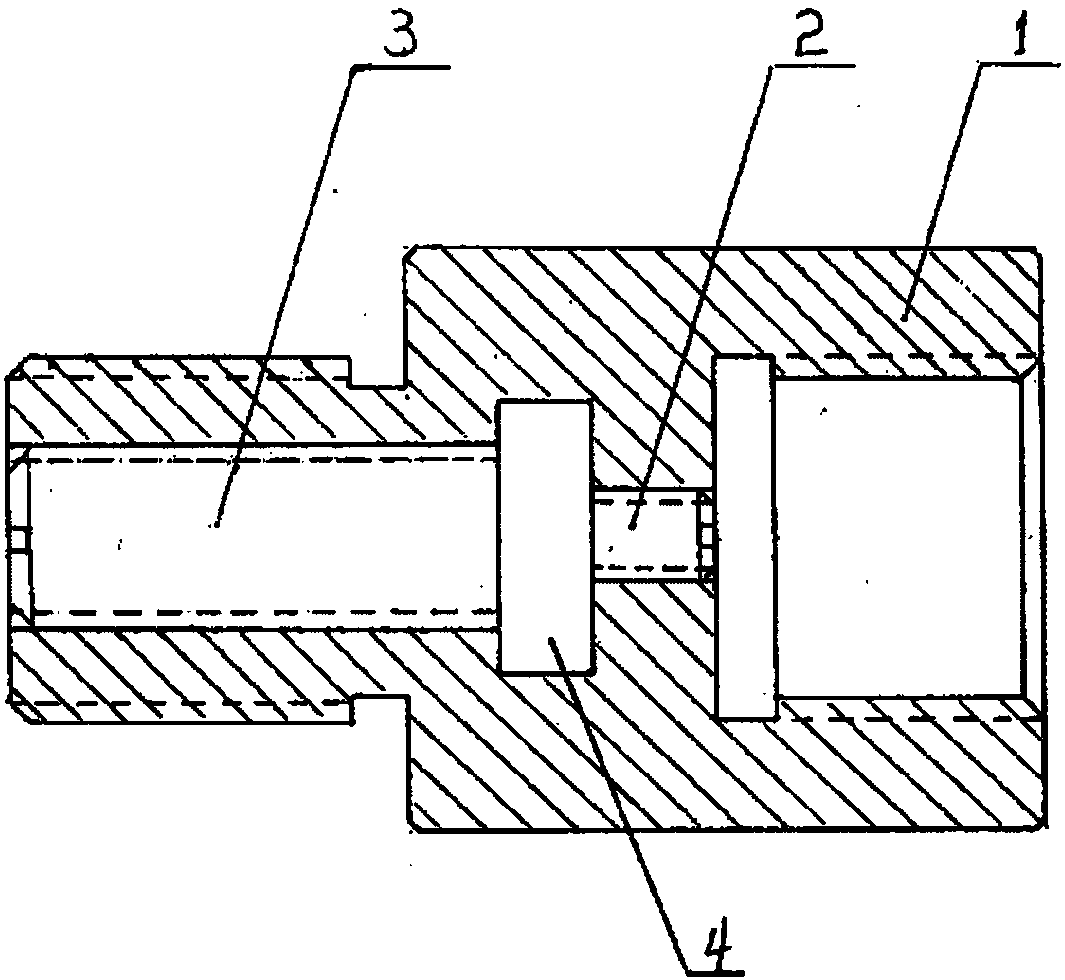

[0008] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0009] With reference to the accompanying drawings, the present invention includes a stabilizer body 1, which is in the shape of a joint, with a primary thread and a secondary thread in the stabilizer body 1, and a thread between the primary thread and the secondary thread. The fluid buffer chamber 4 is provided with a primary helix 3 and a secondary helix 2 on the inner side of the primary thread and the secondary thread respectively. 2 There is a certain gap between the primary and secondary threads corresponding to it.

[0010] When in use, the invention is connected to the pipeline in front of the measuring element, and the measured medium enters the measuring element after flowing through the stabilizer. Since the present invention uses the pressure of the measured medium to be transmitted to the measuring element after passing through the gap between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com