Fixing member and mounting structure

A technology for fixing parts and arms, applied in the installation of connecting parts, incandescent lamp parts, coupling devices, etc., can solve the problem that the protruding part 99 cannot be guided to be inserted into the opening 90, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

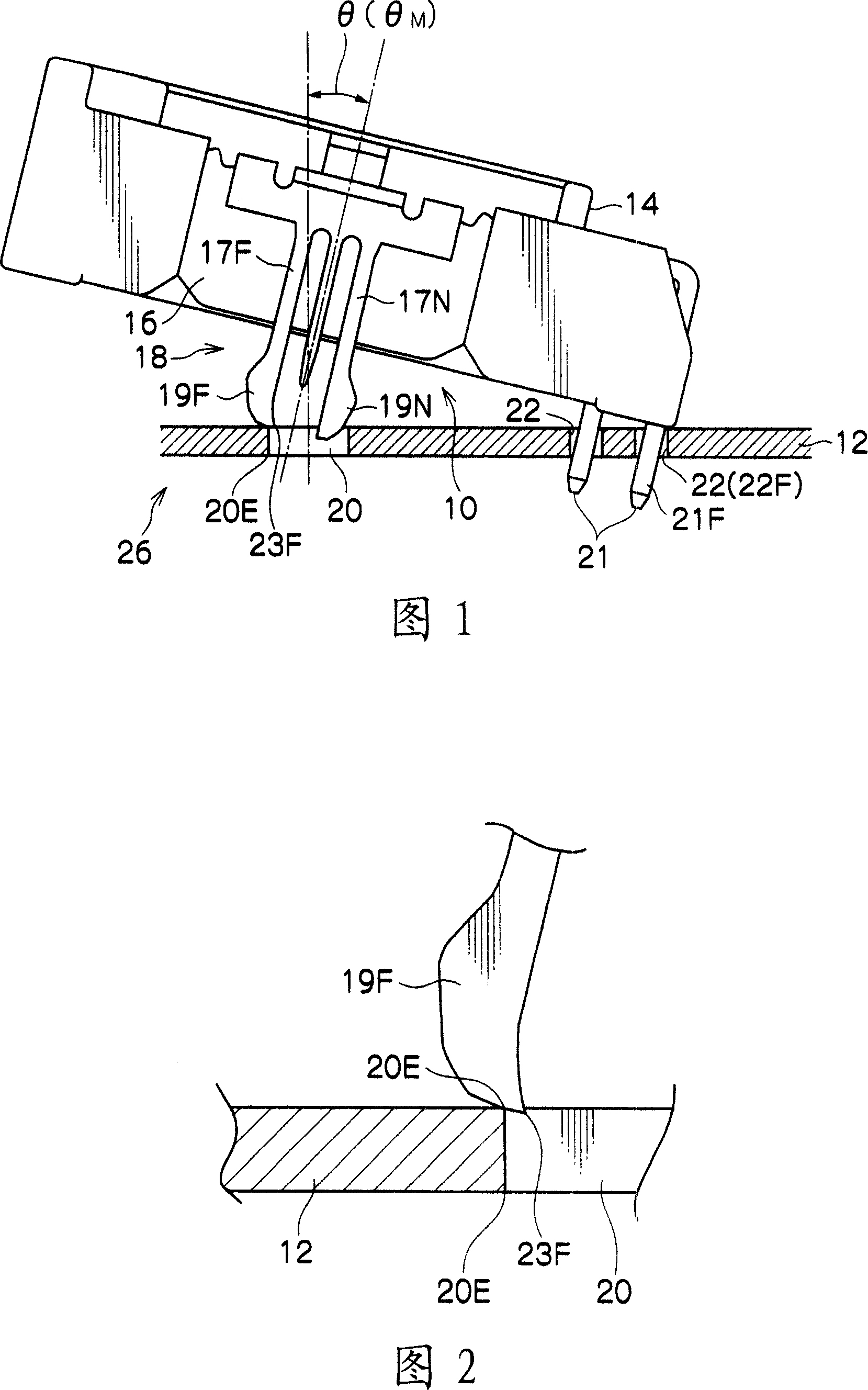

[0028] First, the first embodiment will be described. As shown in FIG. 1 , the fixing member 10 of the present embodiment is a member that can be mounted to an electronic component 14 to be fixed to a printed circuit board 12 .

[0029] The fixing member 10 includes a fixing member body 16 and a male connector portion 18 protruding from the fixing member body 16 , and the male connector portion 18 is a through-hole type connector portion.

[0030] The male connector part 18 has two arm parts 17F, 17N. The arm portions 17F, 17N are respectively provided at their tip sides with protrusions 19F, 19N to be engaged with the opening edge 20E of the insertion opening 20 formed in the printed circuit board 12 .

[0031] A plurality of terminals 21 protrude from the lower surface side of the electronic component 14 . A plurality of insertion holes 22 are formed in the printed circuit board 12 for insertion of corresponding terminals 21 . In this embodiment, as shown in FIG. 1 , an e...

no. 3 example

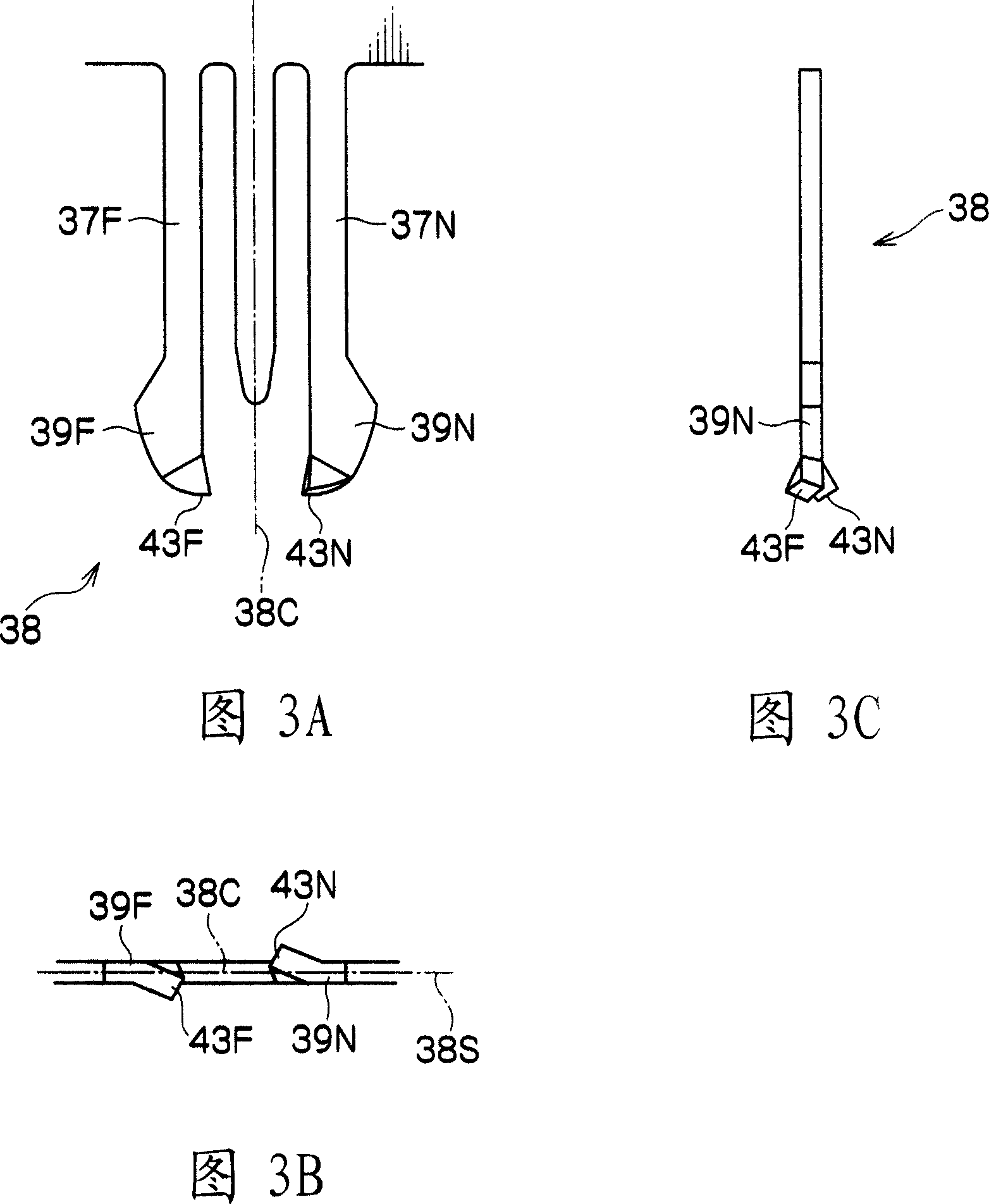

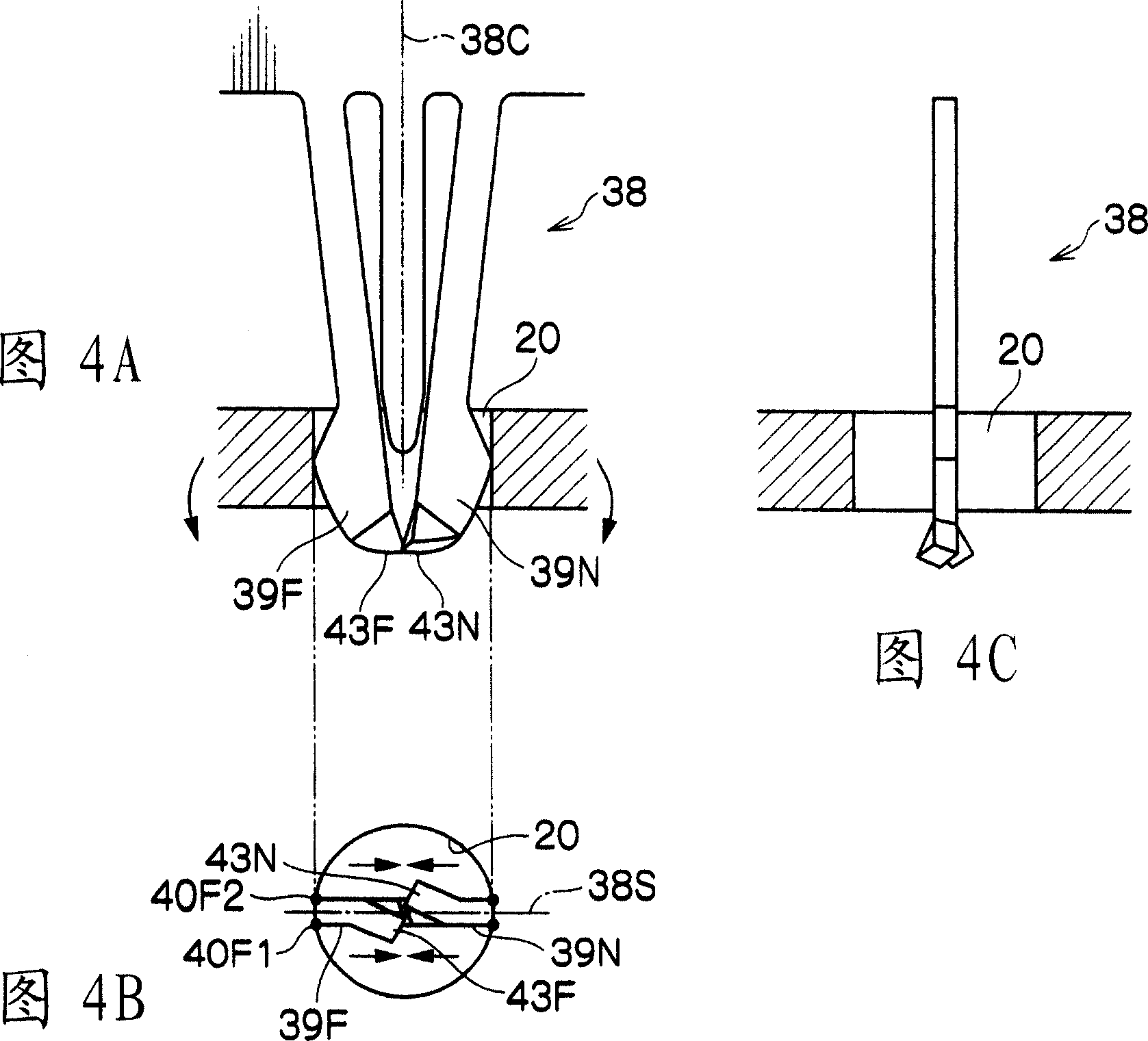

[0049] A third embodiment is described below. As shown in FIGS. 6A to 6C , the fixing member of the present embodiment includes a male connector portion 58 including two arm portions 57F, 57N instead of the two arm portions 17F, 17N of the first embodiment.

[0050] The protrusion 59F of the arm 57F farther from the terminal 21 (see FIG. 1 ) has a protrusion guide 63F, and the protrusion 59N of the arm 57N closer to the terminal 21 also has a protrusion guide 63N.

[0051] In the present embodiment, the dimensions of the protruding guide portions 63F, 63N are set in advance so that the terminal 21 is first inserted into the insertion hole 22 (see FIG. 1 ) to the maximum possible depth and then the male connector portion 58 is inserted toward the insertion opening. When 20 is squeezed, the protrusion guides 63F, 63N come into contact with the opening edge 20E, and the protrusions 59F, 59N are respectively inserted into the insertion opening 20 .

[0052] In addition, in this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com