Profiling comb

A profiling and comb-like technology, applied in the field of profiling combs, can solve the problems of low precision, cumbersome operation process, low efficiency, etc., and achieve the effect of increasing the friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

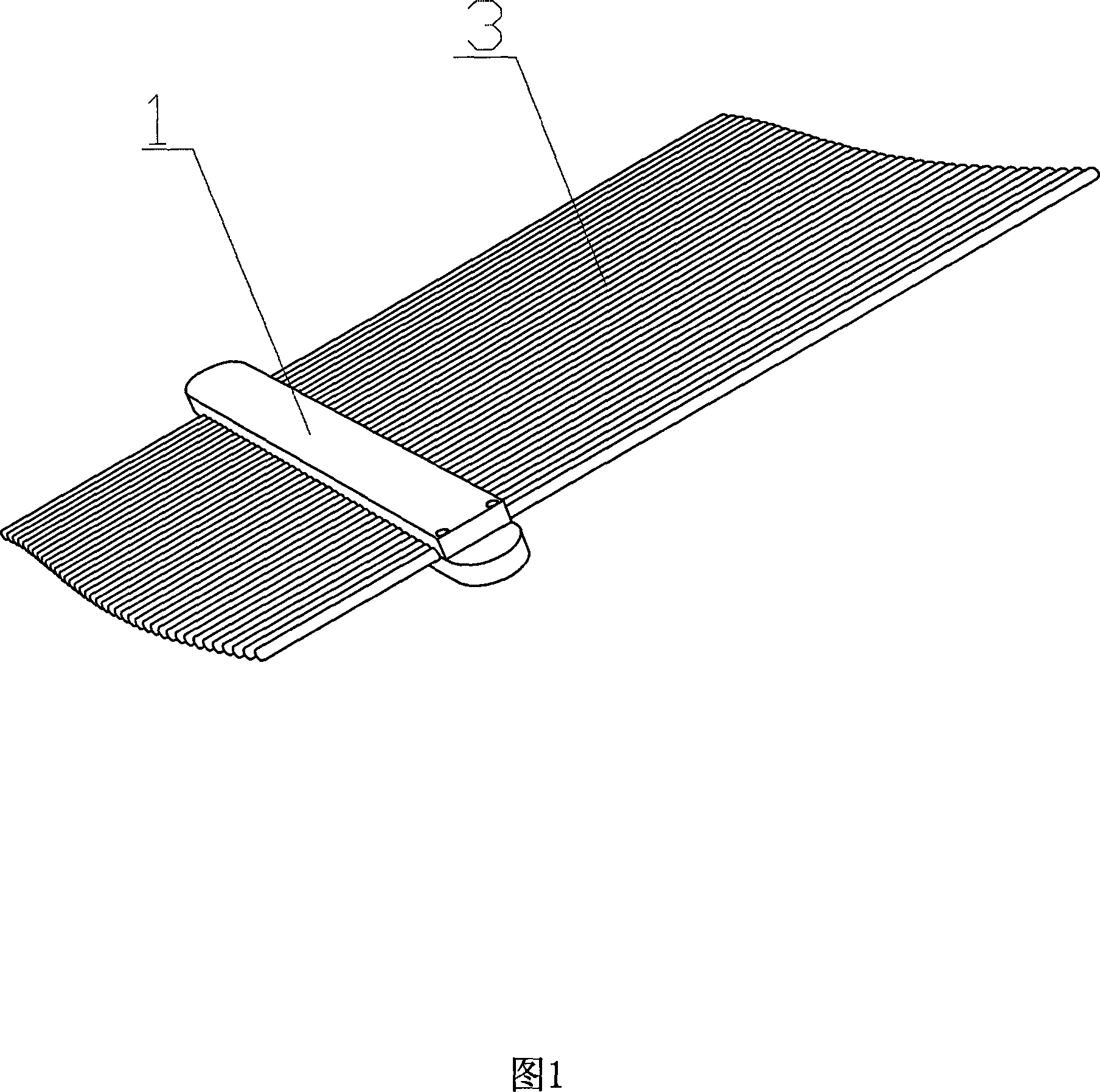

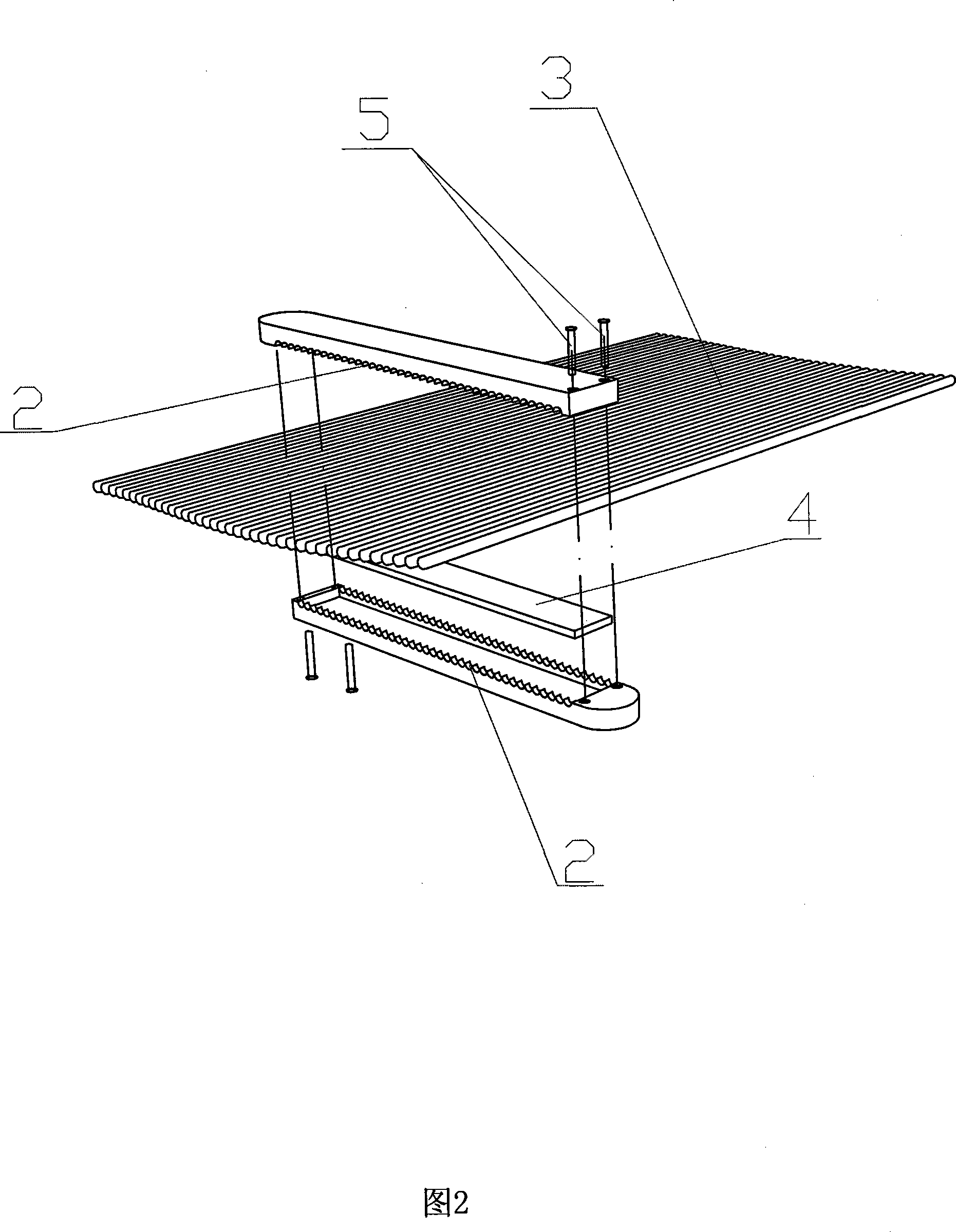

[0015] Embodiment, as shown in Fig. 1, 2: the present invention is mainly made up of profiling clip 1, profiling needle 3, damping sheet 4, and wherein profiling clip 1 is made up of upper and lower two clip bars, and described two clip bars It is a groove-shaped strip, and the top edge of the groove is evenly and continuously distributed with needle pockets 2, the upper and lower clips are butted to make the needle pockets 2 close up to form pinholes, and the profiling needles 3 are inserted into the pinholes to form a "comb shape", There is clearance fit between the profiling needle 3 and the pinhole, and a damping sheet 4 is arranged between the clip bar of the profiling clip 1 and the "comb-shaped" profiling needle 3 .

[0016] In the present embodiment, the two clip bars of the profiling clip have mounting holes at both ends, and the screws 5 pass throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com