Drafting device with four rollers in ring spinner

A technology of ring spinning machine and drafting device, applied in spinning machine, continuous winding spinning machine, drafting equipment, etc. The effect of yarn quality and increasing draft ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

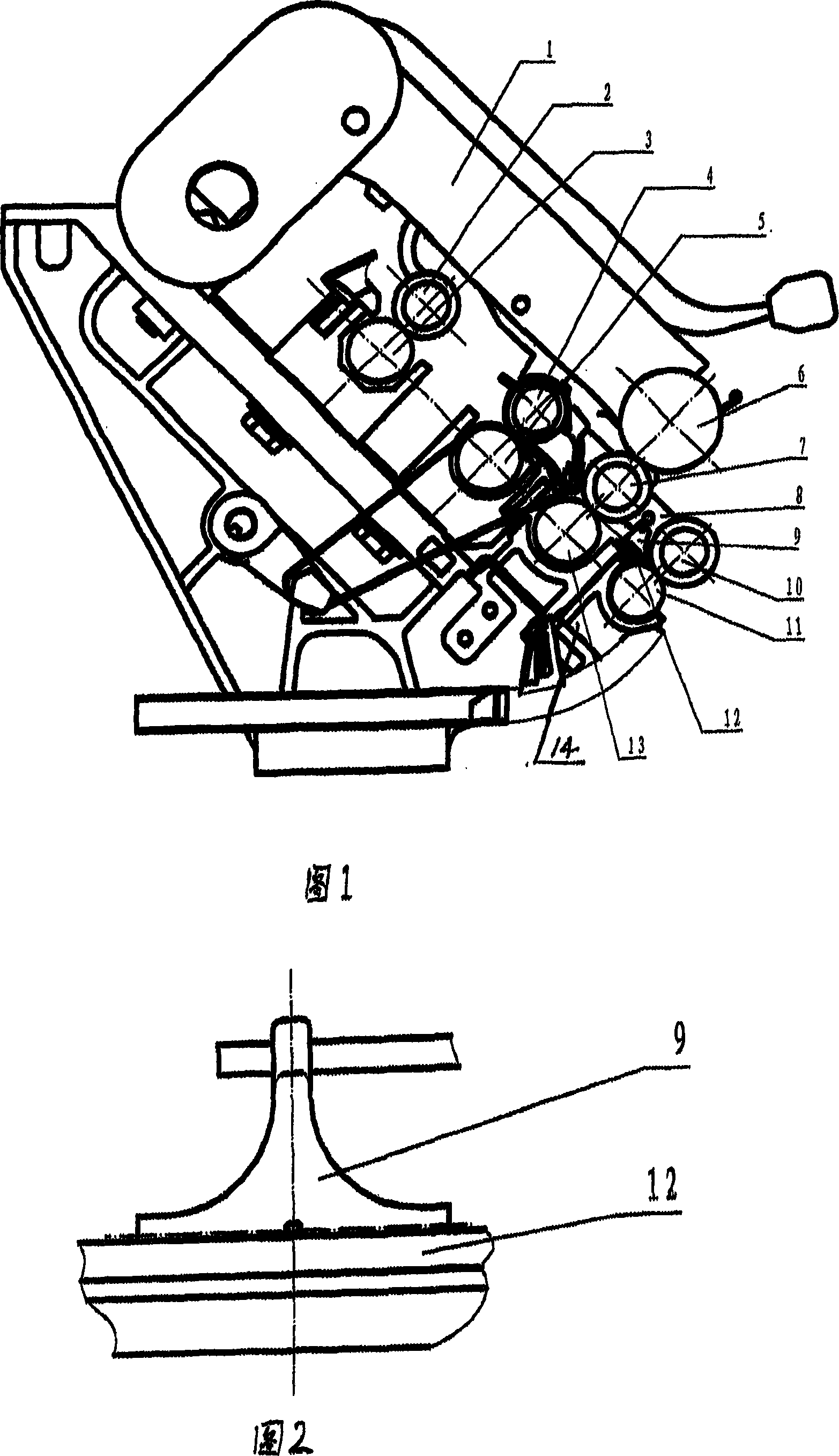

[0008] A four-roller drafting device for a ring spinning machine, which includes a cradle 1, a rear top roller 2, a rear bottom roller 3, a middle top roller 4, a middle bottom roller 5, a front top roller 7, a front bottom roller 13, a finishing Top roller 10, finishing bottom roller 11, support 8, it is provided with support 8 on the cradle 1, is provided with accumulator 9 and finishing top roller 10 on the support 8, is provided with front lower pin 12 and finishing bottom on slide block 14 Roller 11, accumulator 9 and lower pin 12 are arranged on front upper roller 7, front lower roller 13 and sorting upper roller 10, sorting lower roller 11, between accumulator 9 and front lower pin 12, be provided with the narrow gap of 1.1mm seam. Drafting after finishing is 1.05-1.1 times, and the distance between the front bottom roller 13 and the finishing bottom roller 11 is 35mm. The center-to-center deviation of the front top roller 7 and the front bottom roller 13 is 2mm. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com