Accurate collecting device for carding machine cotton layer thickness

A collection device and layer thickness technology, applied in the field of carding machines, can solve the problems that the cotton layer thickness data acquisition system cannot meet the requirements and are inaccurate, and achieve the effect of scientific and more accurate cotton layer reference parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

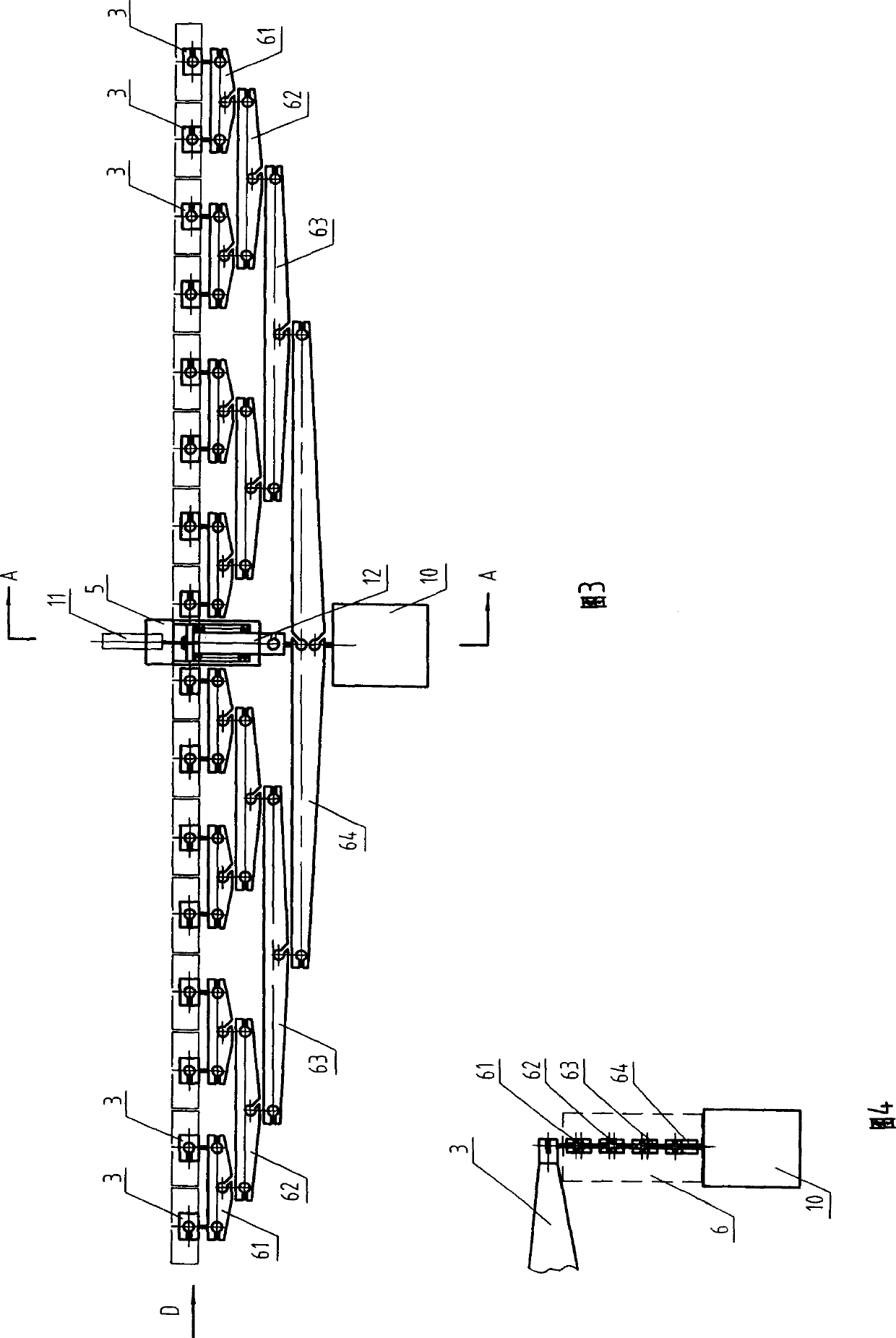

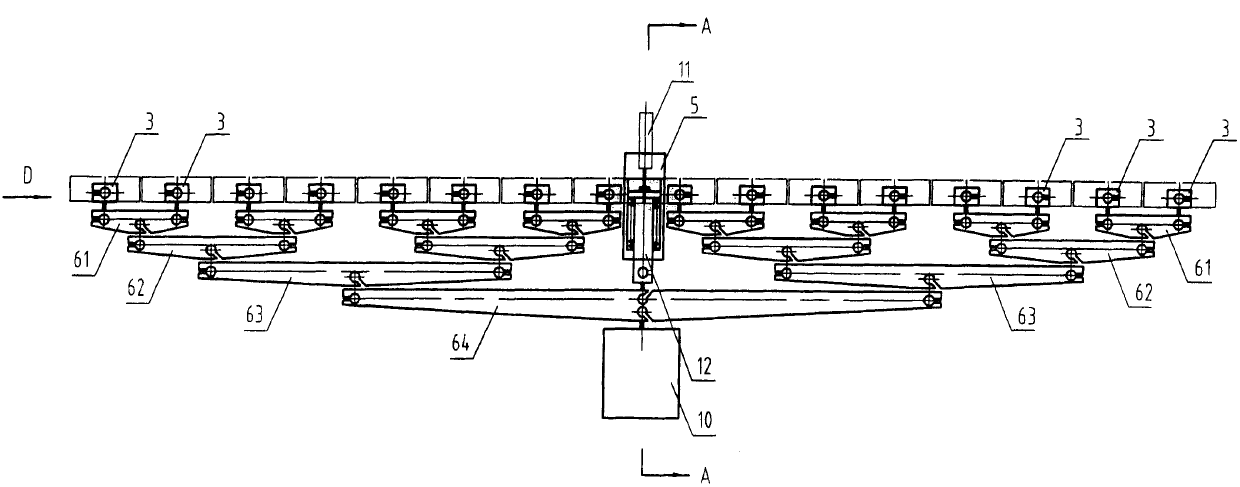

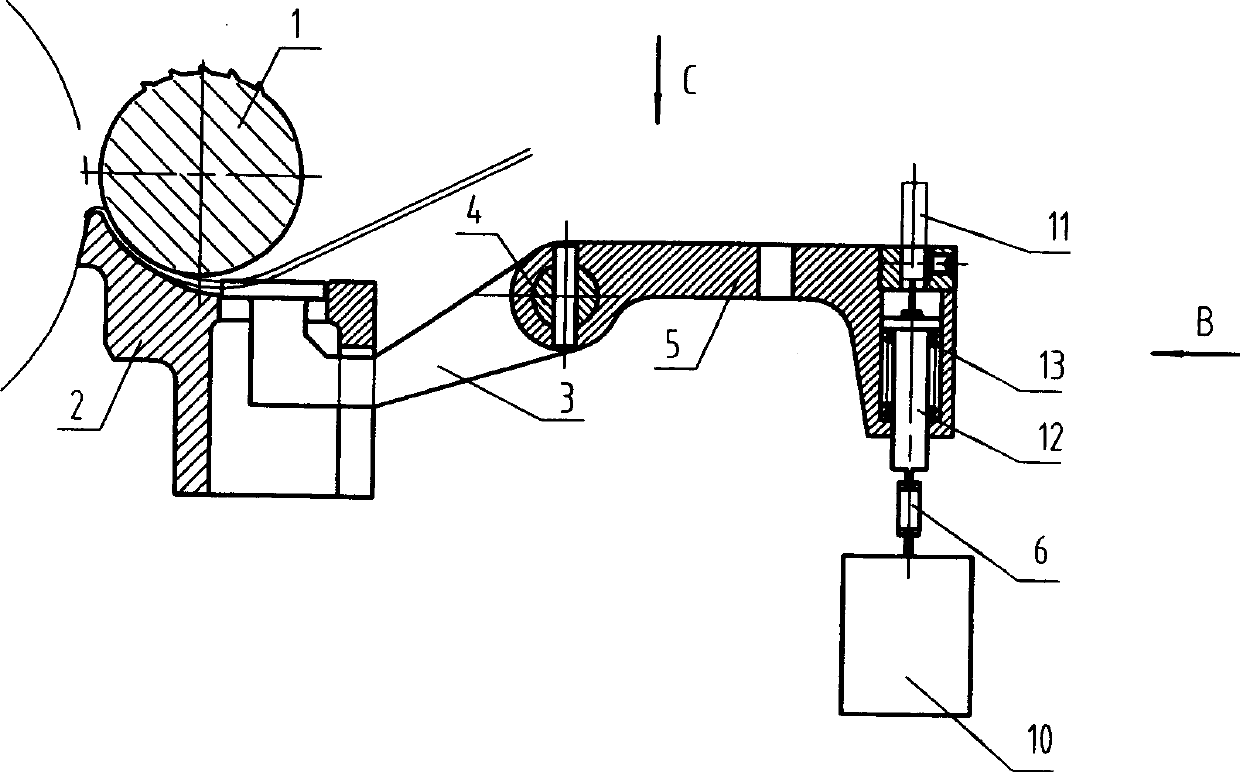

[0021] As attached figure 1 As shown in -4, the precise collection device for cotton layer thickness of the carding machine includes a cotton feeding roller 1, a cotton feeding board 2 and a measuring rod 3. The cotton roller 1 is fixed and the measuring rod 3 is set on the cotton feeding plate 2 and the measuring rod 3. Between the feed rollers 1, sixteen detection areas are evenly set in the length direction of the cotton feed rollers. Each detection area is provided with a measuring rod 3, and the sixteen measuring rods 3 can be freely rotated through the spacer 7. Covered on the supporting shaft 4, the cotton feeding roller 1 acts on the measuring end of the measuring rod 3 through the cotton layer. The output end of the measuring rod 3 is movably connected with the terminal balance rod 64 of the balance transfer structure 6, and the upper end of the terminal balance rod 64 is connected to the pull rod 12 is movably connected, the lower end is movably connected with the bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com