Lamp with infrared reflection coating

A technology for electric lamps and filaments, which is applied to circuits, incandescent lamps, electrical components, etc., and can solve the problems of returning to the filament to reflect infrared radiation interference, support structure shadows, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

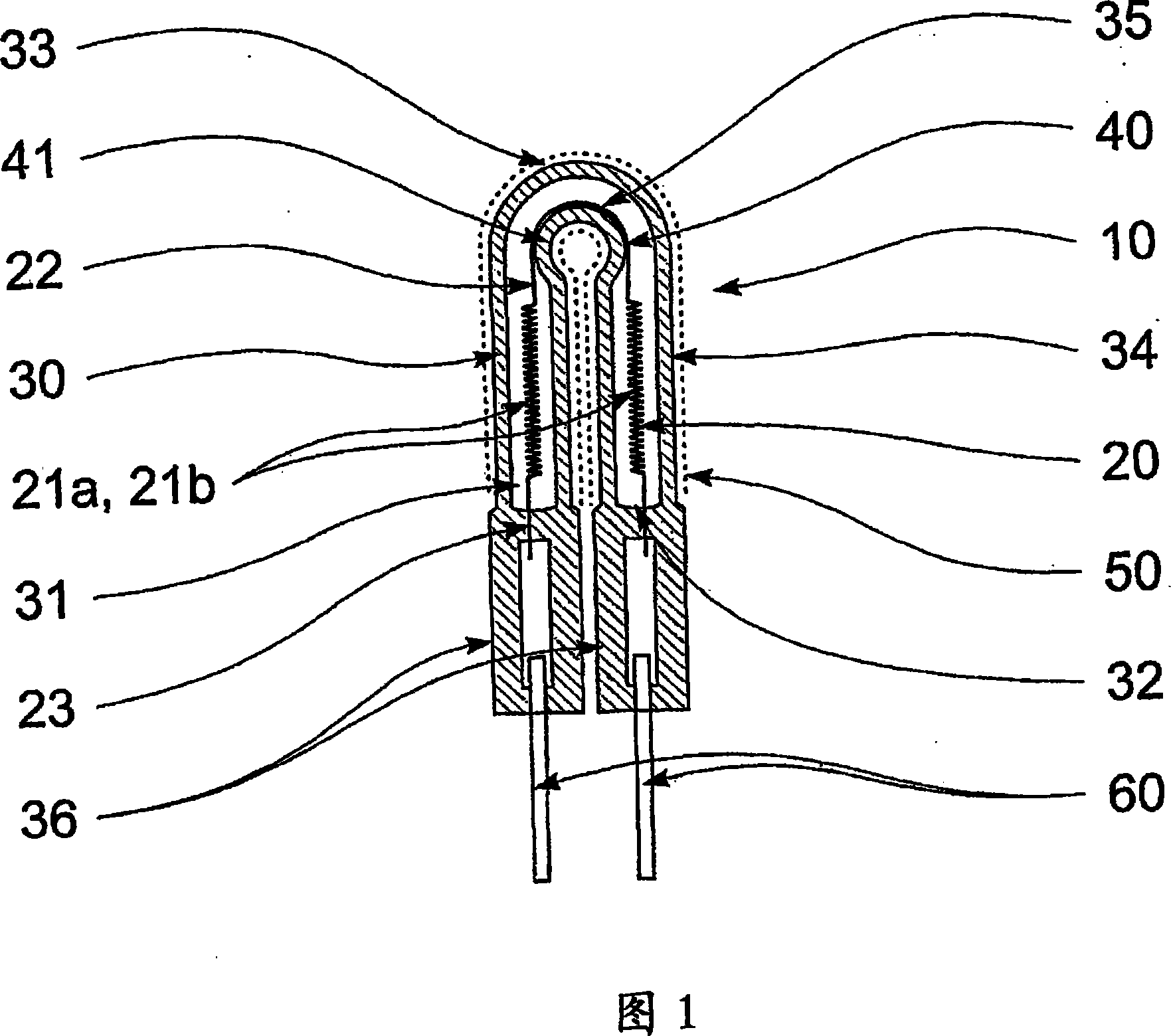

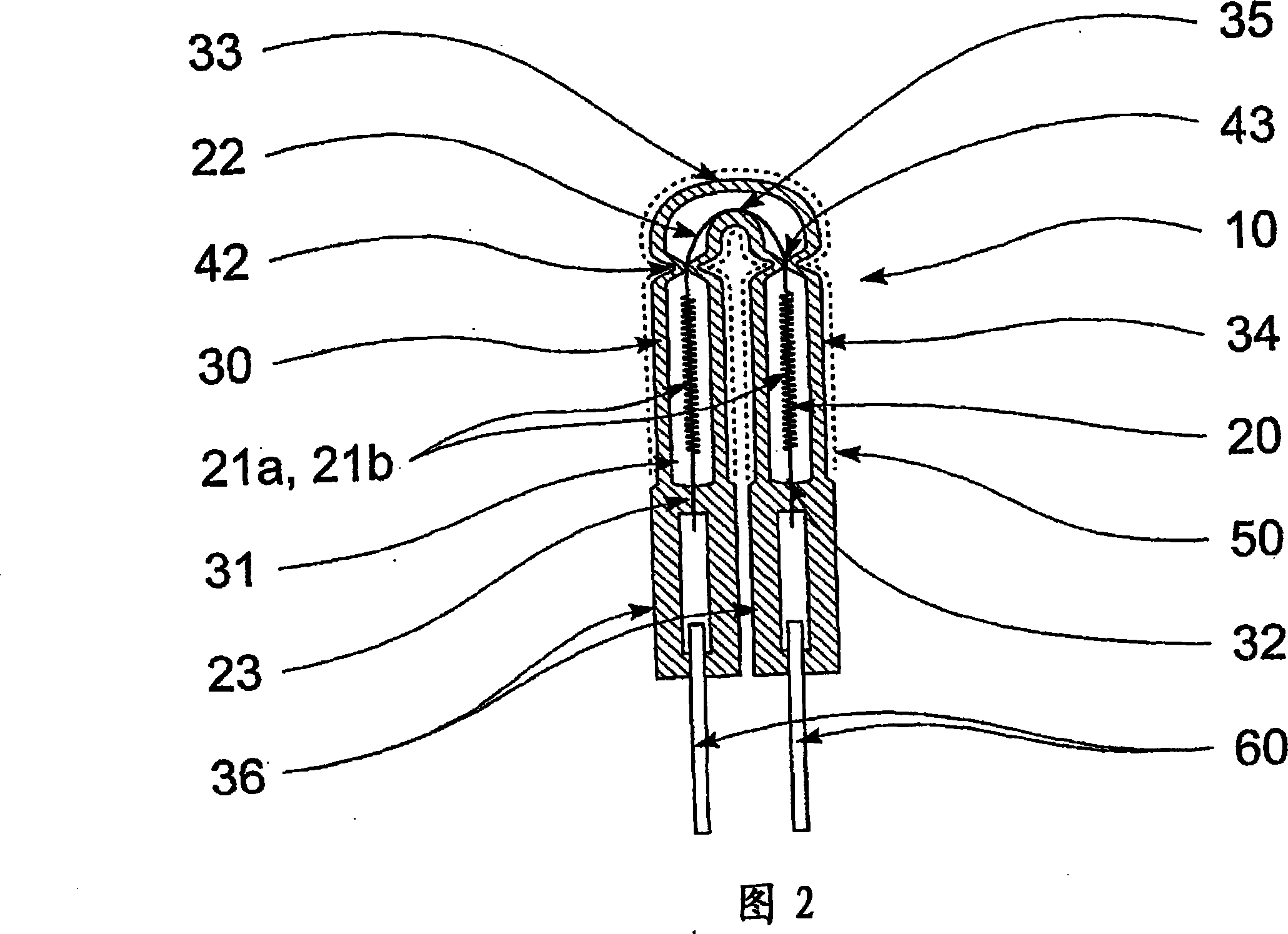

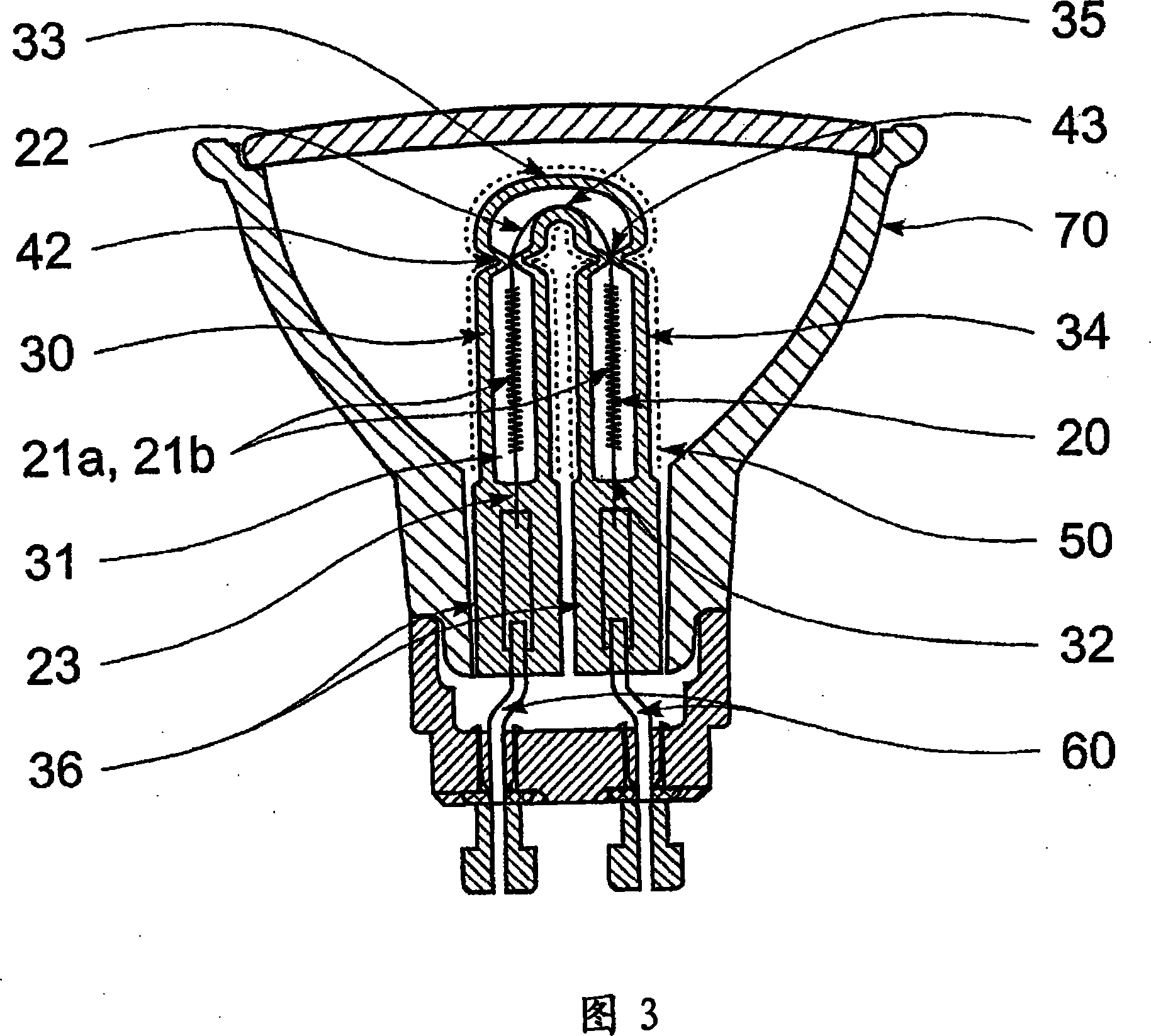

[0022] Figure 1 shows a first embodiment of a luminaire 10 according to the invention. The electric lamp 10 comprises a filament 20 housed within a quartz tube 30 . Inside the quartz tube 30 there is a hollow central region 31 in which the filament 20 is accommodated. As can be seen, the quartz tube 30 has a substantially U-shaped geometry such that the two end regions 34 of the tube are substantially adjacent to each other. Connecting the two end regions 34 together is a U-bend region 33 which is preferably bent such that the two end regions 34 of the quartz tube 30 are very close to each other. It is further desirable that the axes along the center of the quartz tube 30 in each end region 34 be parallel to each other. It can also be seen from the figure that the hollow central region 31 does not extend along the full length of the quartz tube 30 but is actually sealed in a hermetic manner at each end 32 of the quartz tube 30 . This simple design results in an easily manuf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com