Extrusion nozzle for extruding hollow profiled elements

A profile and hollow technology, applied in the field of extrusion nozzles, can solve the problems of reducing strength and high processing cost of extrusion nozzles, and achieve the effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

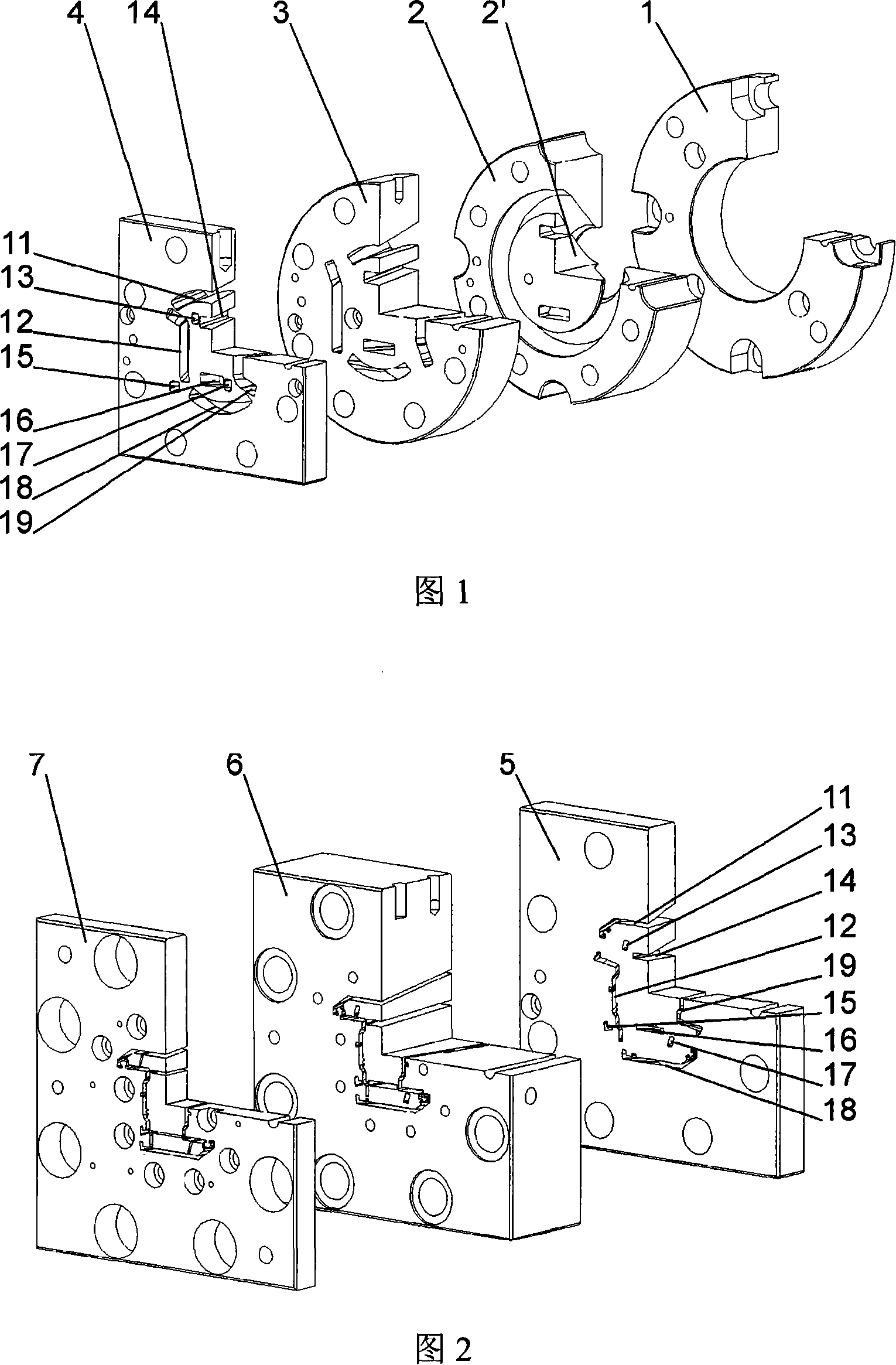

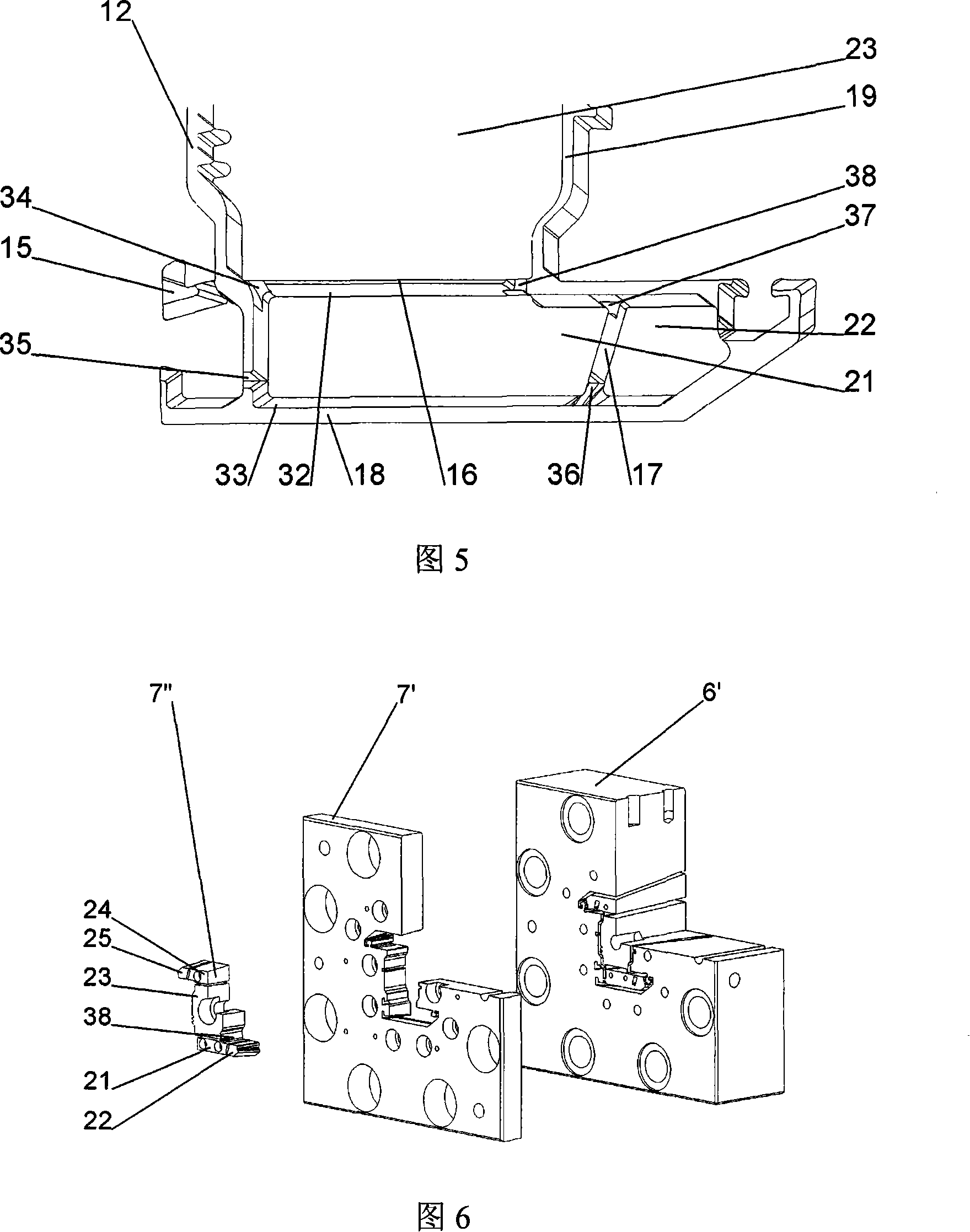

[0028] Starting from a circular melt flow in flange plate 1 ( FIG. 1 ), the melt flow is transformed into a circular shape in distribution plate 2 with spreading tip 2 ′. Here, the melt stream is reshaped into a shape that is larger than the desired size. The residence time of the extrudate is thus extended, which allows the material to be homogenized to a certain extent, which is necessary to increase production efficiency. This circular shape is then subdivided again in the other plates 3 and 4 by segment-shaped flow channels 11 - 19 . These segmented runners 11-19 themselves form separate, independent runners whose shape and position correspond to those of the finally produced profiles.

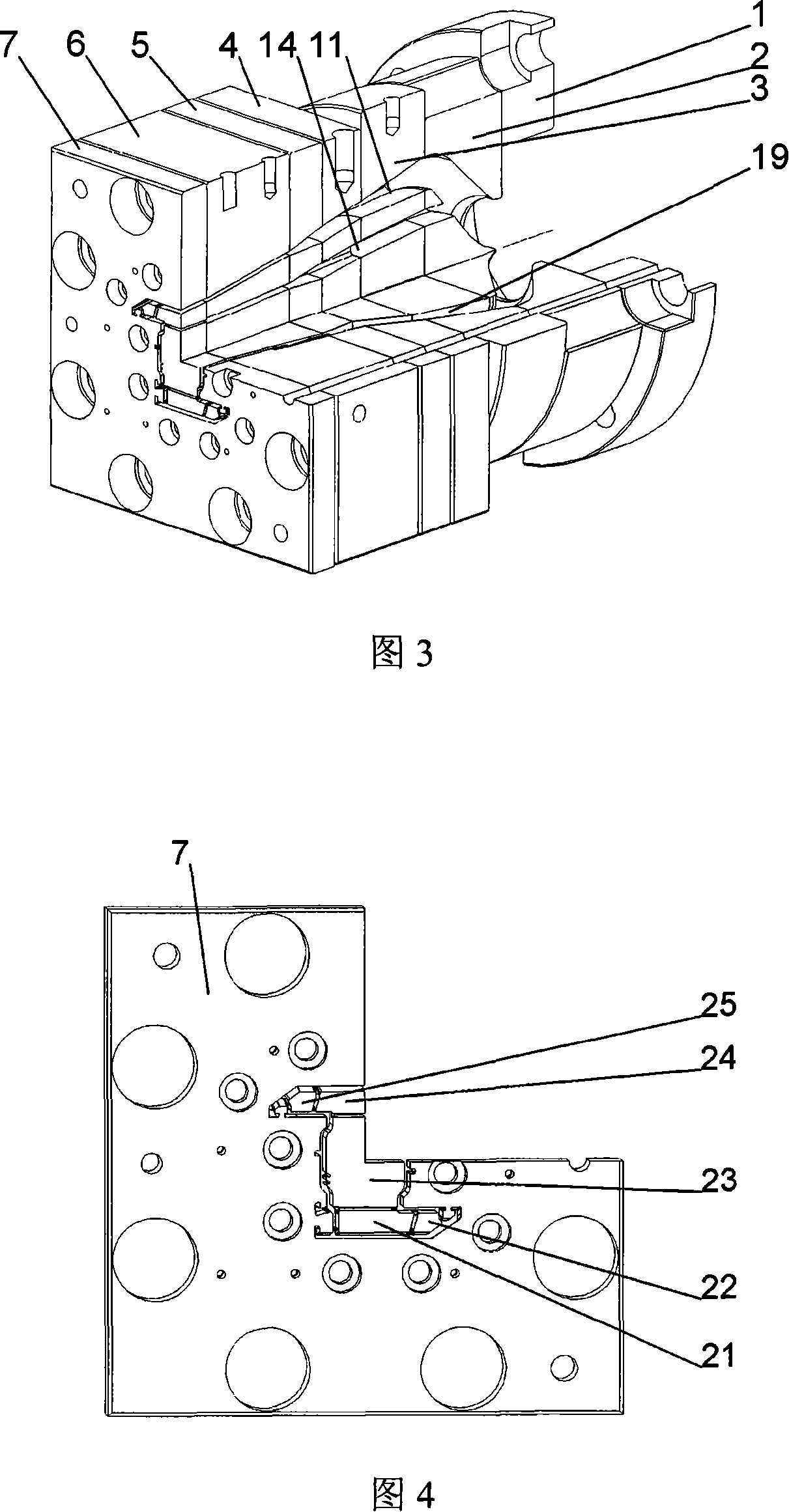

[0029] In subsequent plates 5 , 6 and 7 ( FIG. 2 ), the segment-shaped flow channels 11 - 19 are gradually adjusted in position and thickness to the subsequent profile shape. The core part of the present invention is that these segmented flow channels 11-19 are independent of each other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com