Method for preparing bioartificial heart valve material by cross-linking quercetin

A heart valve, quercetin technology, applied in the field of biomedical engineering, can solve problems such as fragility, brittleness, and weakening of the mechanical strength of biological valves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

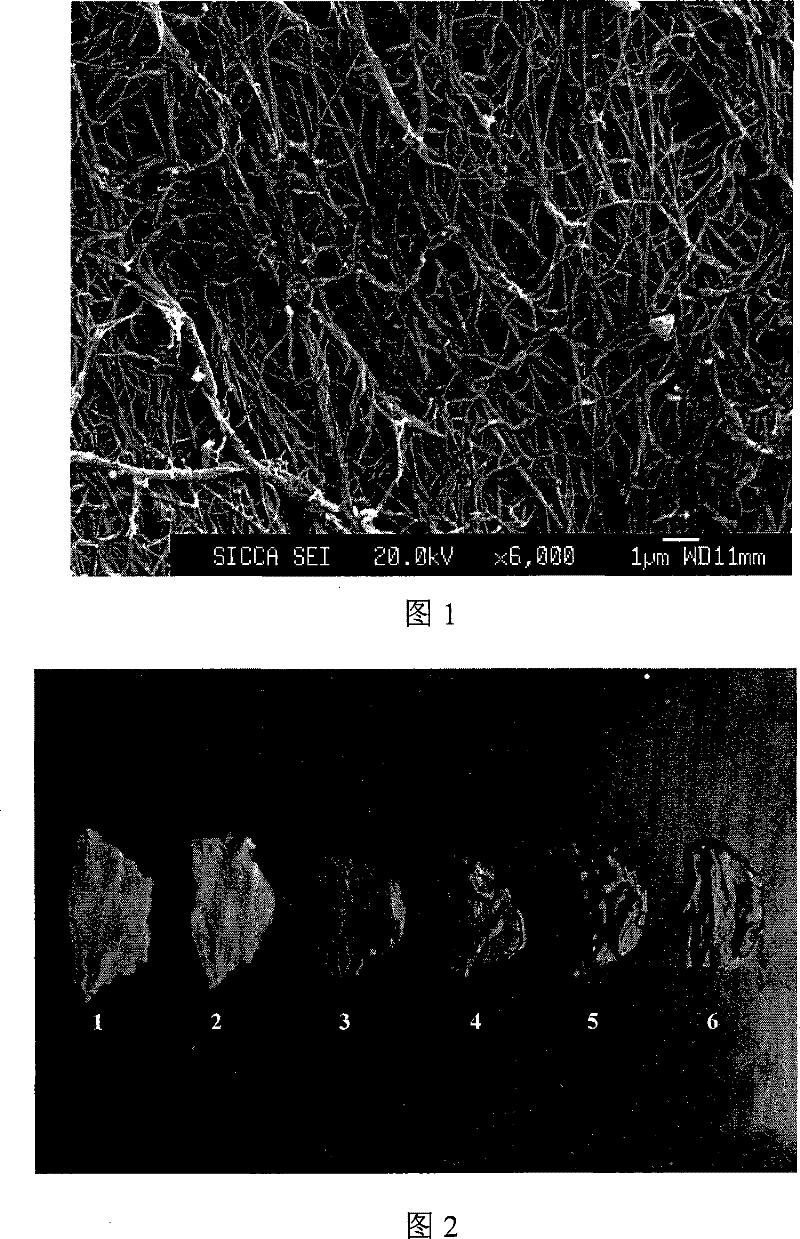

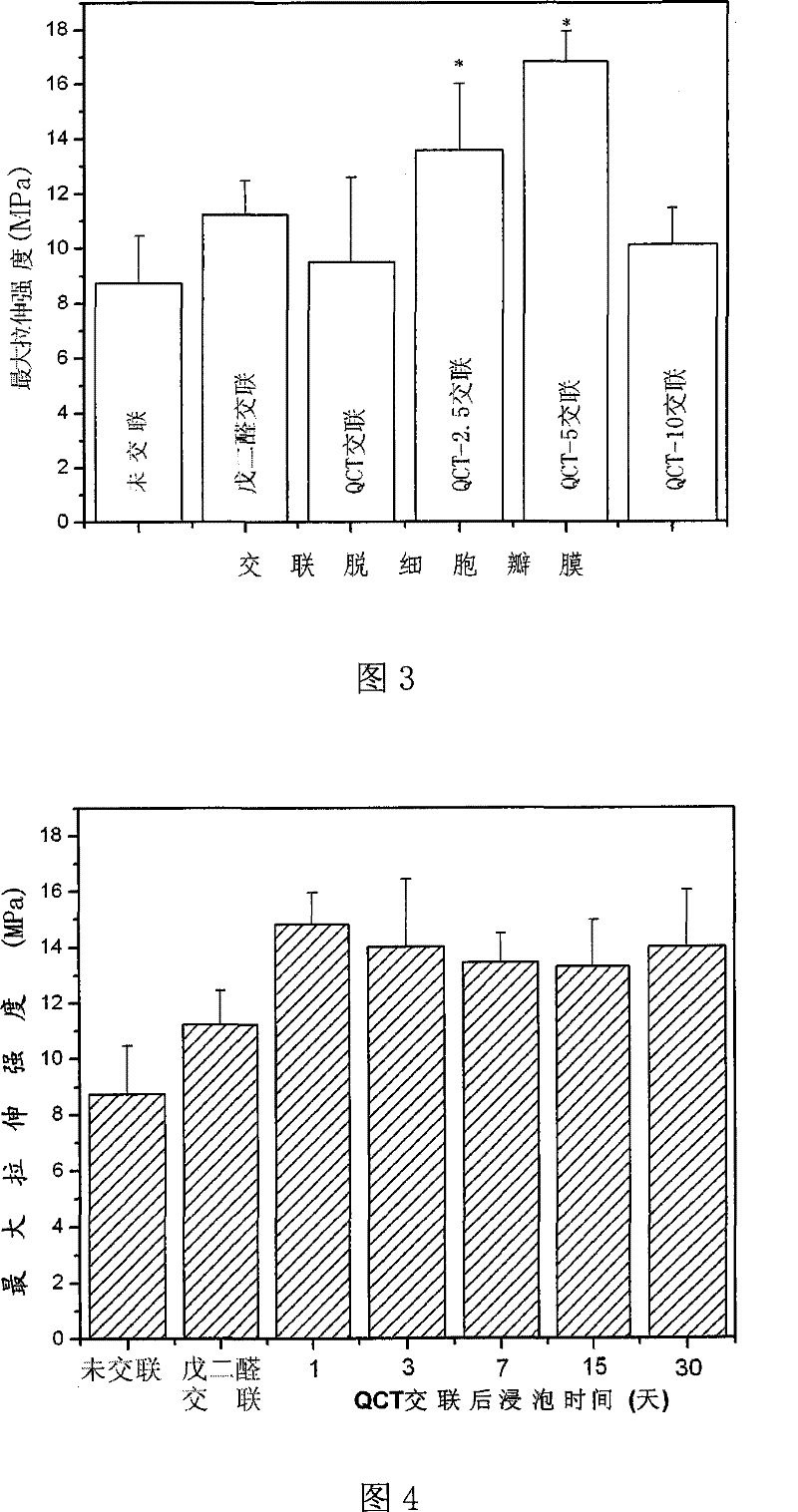

[0056] Use the balanced salt buffer D-Hanks solution at 1-6°C as the storage and transportation solution, take the fresh porcine aortic heart valve from the slaughterhouse, cut the valve leaflets at 4°C within 4 hours, and use D-Hanks Fluid clean. Afterwards, the decellularized porcine heart aortic valve was prepared according to the aforementioned method, and washed cleanly to obtain the following: figure 1 Structure and shape of decellularized valve materials. Then add 2ml of quercetin to each valve to soak in ethanol-containing D-Hanks special solution, shake and cross-link at 120rpm at 37°C for 48 hours. Add 2ml of D-Hanks solution to each valve to soak the valve, shake and wash at 120rpm at 37°C for 48 hours, and repeat the washing 3 times. The obtained biological valve material was evaluated for the above performance. figure 2 Middle 2 is a decellularized valve cross-linked with 6.25 mg / ml glutaraldehyde, which is as loose as the non-cross-linked decellularized valve...

Embodiment 2

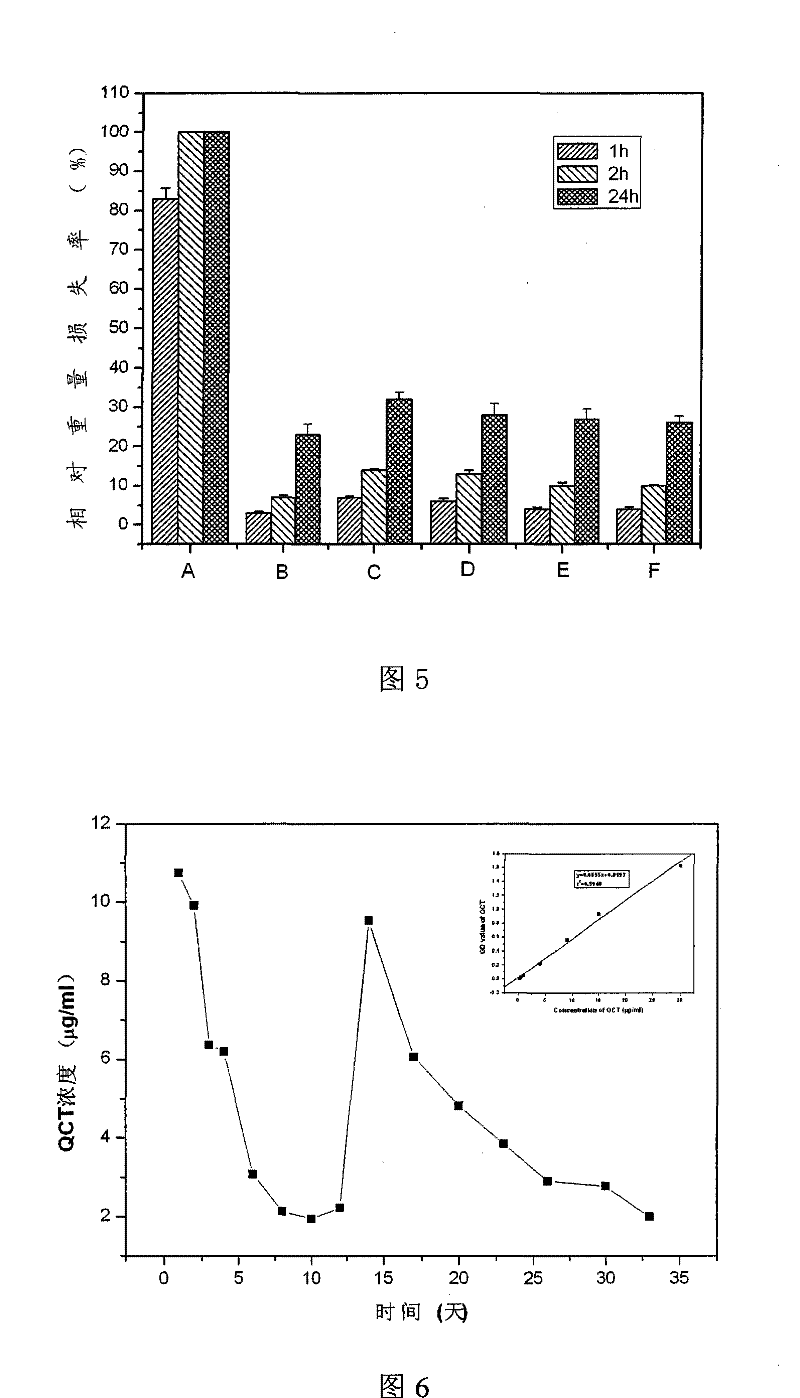

[0058] Prepare the decellularized porcine heart aortic valve according to the method described in the summary of the invention and clean it, add 2.5mg / ml quercetin-containing D-Hanks special solution with ethanol at a ratio of 2ml per valve. Example 1 Method Cross-linking, the resulting cross-linked biological valve material can also maintain the original shape of the valve, soft and moist without shrinking. image 3 The maximum tensile strength of the decellularized valve cross-linked by 2.5 mg / ml quercetin was 13.9 MPa. Figure 5 It was shown that only 28.5% of the decellularized valves cross-linked with 2.5 mg / ml quercetin were degraded after 24 hours of enzymatic hydrolysis. It shows that this concentration of quercetin also has a cross-linking effect on the decellularized valve, and has good mechanical properties and stability against enzymolysis.

Embodiment 3

[0060] Get fresh porcine aortic heart valve from slaughterhouse by the method of embodiment 1 and clean up. After washing with D-Hanks solution three times, valve cells were removed by shaking with decellularization solution at 60 rpm at 4°C for 96 hours. Use D-Hanks solution to shake the decellularized heart valve material at 21°C (room temperature) at 120rpm to wash valve cell residues, debris, free protein, nucleic acid and other macromolecules for 96 hours. Add 0.1mg / ml, 0.2mg / ml, 0.5mg / ml, 2mg / ml and 5mg / ml quercetin in ethanol-containing D-Hanks special solution at a rate of 20ml per valve, at 20°C, at 240rpm shaking speed, cross-linked for 96 hours. Add 20ml of D-Hanks solution to each valve to soak the valve, and wash at 120rpm for 10 minutes at room temperature. The bioprosthetic valve material of the present invention that makes like this is done aforementioned performance evaluation, and its maximum tensile strength is respectively 10.4MPa, 12.5MPa, 14.4MPa, 14.9M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com