Material sonic velocity measurement method

A measurement method and technology of sound speed, which are applied in measurement devices, measurement of propagation speed, measurement of ultrasonic/sonic/infrasonic waves, etc., to achieve the effect of solving the difficult problem of material sound speed measurement

Active Publication Date: 2010-09-15

STATE GRID HEBEI ELECTRIC POWER RES INST +2

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003]The premise of the above-mentioned commonly used methods to measure the sound velocity of materials is that the sample can be cut from the workpiece to be tested or the thickness of the test piece can be accurately measured by mechanical means, but in the engineering site When measuring the sound velocity of a certain workpiece material, destructive sampling of the workpiece is often not allowed, and even the wall thickness of the workpiece cannot be measured by mechanical methods due to the structure of the workpiece, so the above-mentioned conventional methods cannot be used to measure the sound velocity of the workpiece material

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0038] When the destructive sampling of the workpiece is not allowed on the engineering site, or the wall thickness of the workpiece cannot be measured mechanically due to the structural reasons of the workpiece, the sound velocity of the workpiece material can be measured by using the technical solution described in the above summary of the invention. Measurement.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

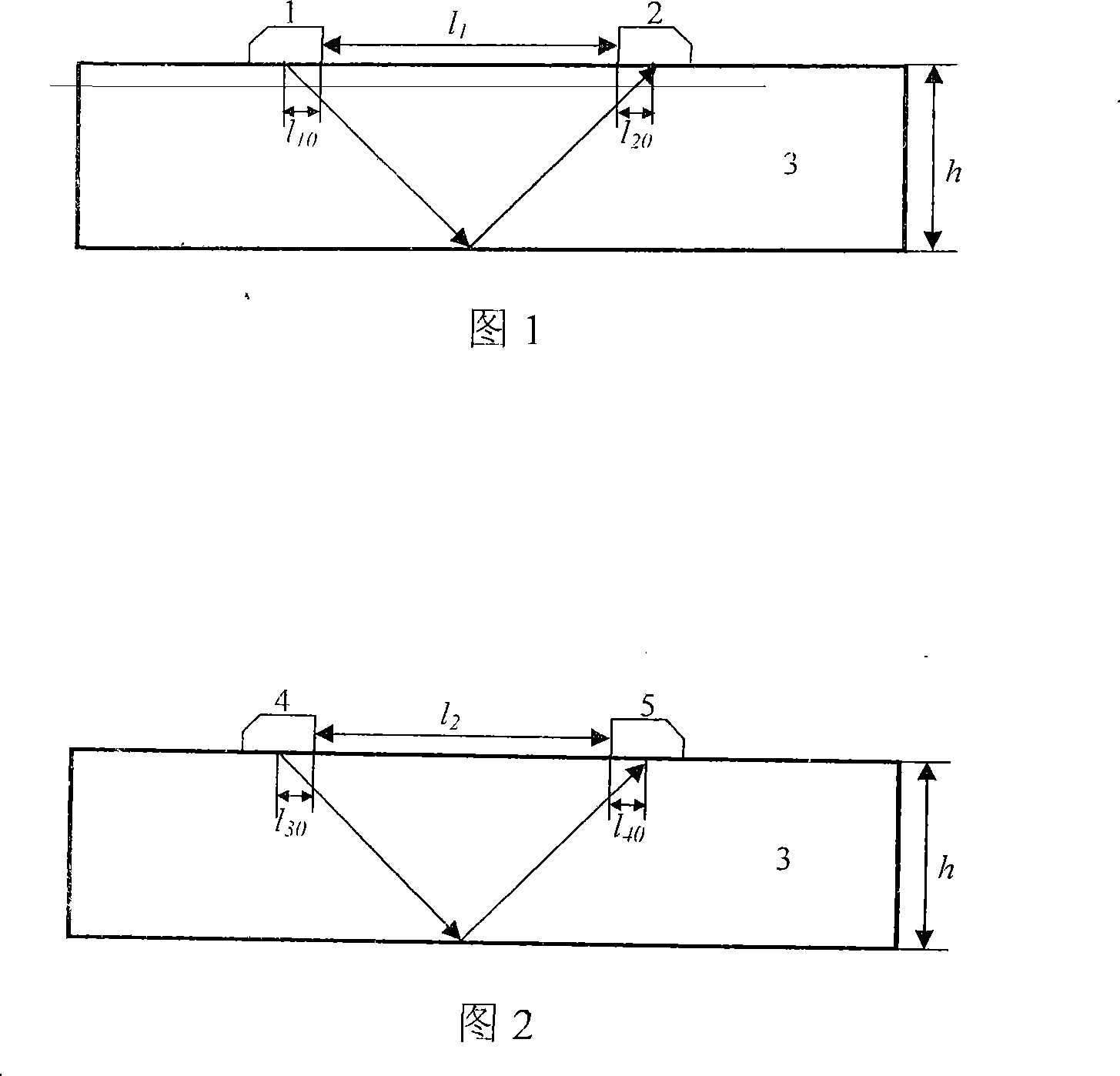

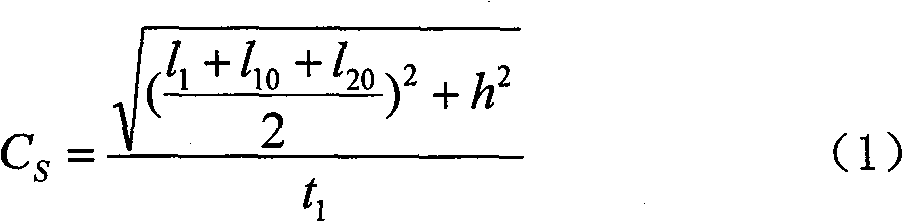

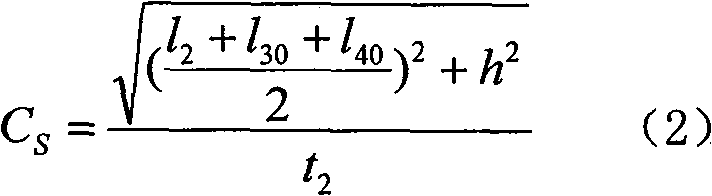

The invention relates to a material sound velocity measuring method. The sound velocity of the ultrasonic transverse wave of the work piece material is calculated by measuring the travel time of the ultrasonic transverse wave in work material for two times and using the method for respectively ultrasonic transverse wave incidenting and being received at different angle. The sound velocity of the ultrasonic longitudinal wave and the sound velocity of the ultrasonic surface wave are calculated based on the travel velocity relation of the sound velocity of the ultrasonic transverse wave respectively with the sound velocity of the ultrasonic longitudinal wave and the sound velocity of the ultrasonic surface wave. The sound velocity of the work piece with unknown thickness at project site can be measured. The method is convenient and practical.

Description

technical field [0001] The invention relates to a method for measuring sound velocity of a material. Background technique [0002] At present, the principle of the material sound velocity measurement method stipulated by domestic and foreign standards is to cut the sample from the workpiece to be tested, and after accurately measuring the thickness T of the sample and the propagation time t of the ultrasonic wave in the sample, according to the relationship Calculate the speed of sound V. [0003] The premise of the above-mentioned commonly used method to measure the sound velocity of the material is that the sample can be cut from the workpiece to be tested or the thickness of the test piece can be accurately measured by mechanical means. However, when measuring the sound velocity of a certain workpiece material at the engineering site, it is often not allowed to For destructive sampling, even the wall thickness of the workpiece cannot be measured mechanically due to the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01N29/07G01H5/00

Inventor 张彦新牛晓光李中伟刘长福郝晓军王志永董国振

Owner STATE GRID HEBEI ELECTRIC POWER RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com