Wheel construction

A technology for rims and tires, applied to rims, transportation and packaging, vehicle parts, etc., can solve the problem that the bead is not directly on the rim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

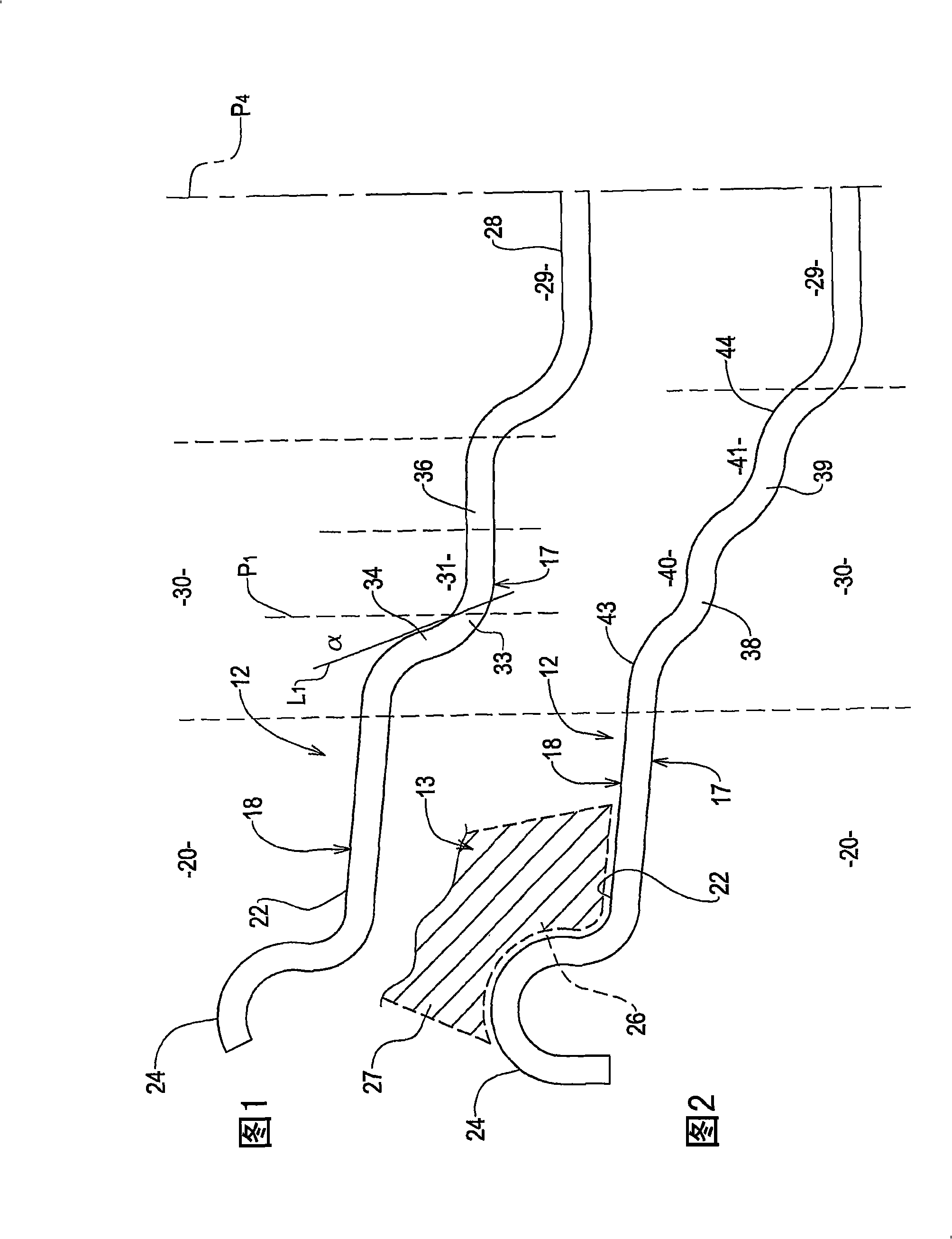

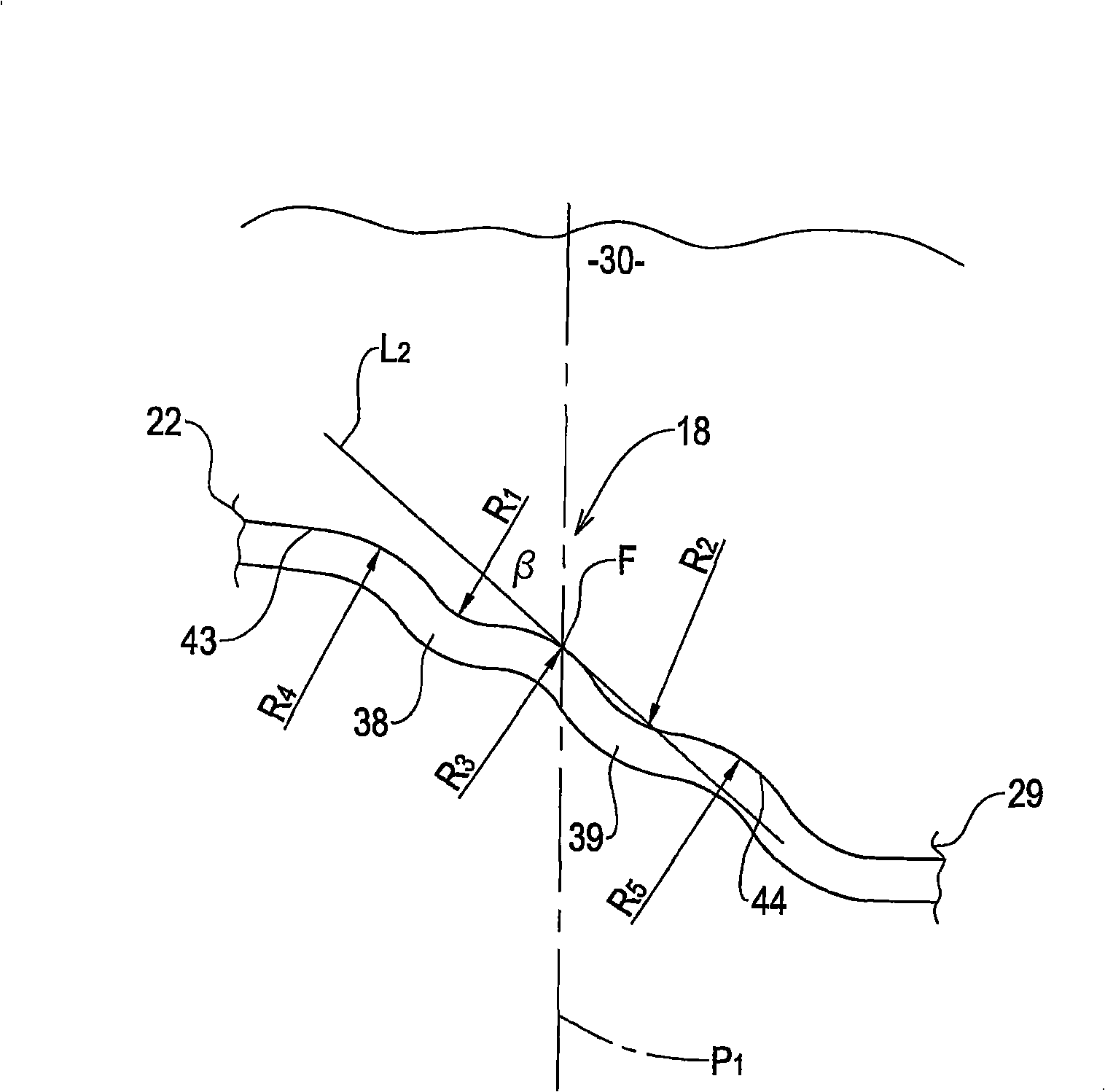

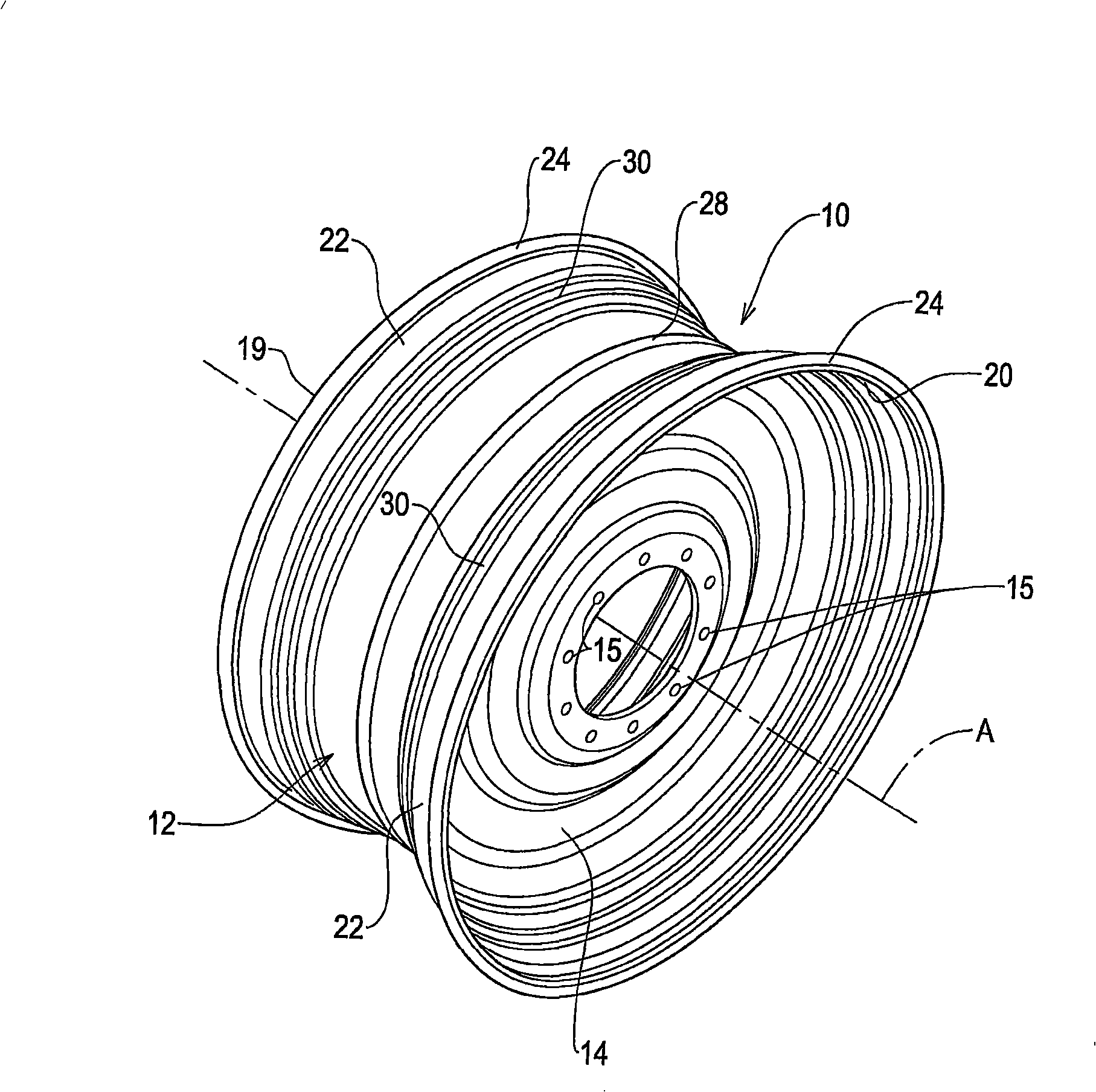

[0026] Referring to the drawings, a wheel structure 10 typically used for tractors, industrial machinery, etc. comprises a rim 12 on which, in use, a tire 13 (a portion of the tire is shown in phantom in FIG. 2 ) is mounted; The wheel structure 10 may be connected to a hub or axle of a tractor, industrial machine or the like via the spokes.

[0027] The spokes 14 include a plurality of openings 15 for receiving bolts or other fasteners for this purpose; Figure 4 In one example, the rim 12 is permanently affixed to the spokes 14 by welding, but in other examples, the rim 12 may be attached to the rim 12 by fasteners, as has been widely accepted in the art, which may be The axial position of the rim 12 is enabled to be varied relative to the hub or axle of the vehicle, thereby varying the distance between a pair of wheels rotating about a generally common axis A.

[0028] The rim 12 is circular in shape with a radially inner surface 17 and a radially outer surface 18 ;

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com