Method and device for removing leads from the twist machine and placing into stator and rotor groups

一种扭转器、定子组的技术,应用在绕组、电动组件、制造电动发电机等方向,能够解决不适合大批量生产、劳力高度密集、程序缓慢等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

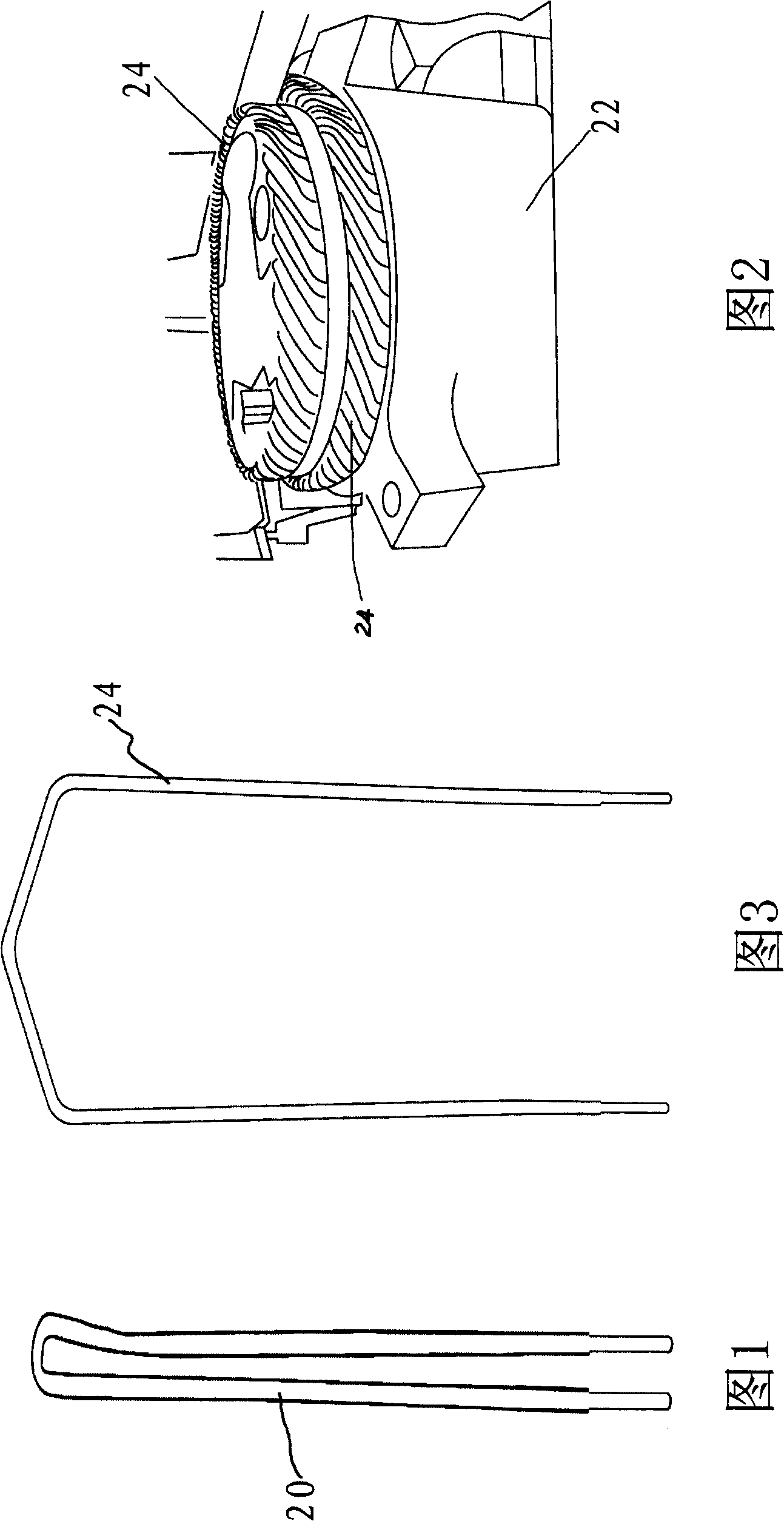

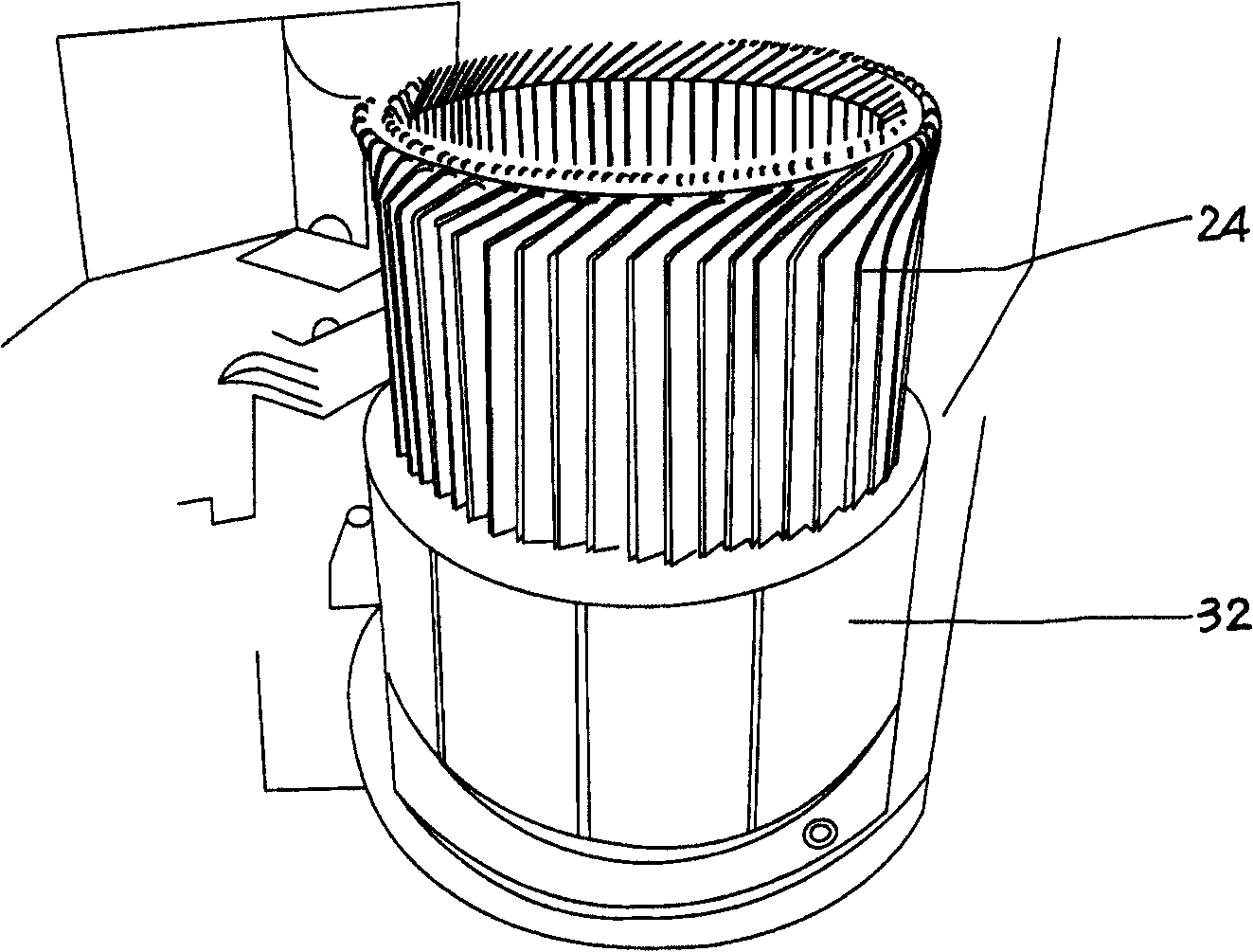

[0031] The object of the invention is to simultaneously remove all rectangular winding wires from the torsion jig and place the wires on the desired rotor or stator core. In particular, a rectangular insulated wire with stripped ends is bent to form a hairpin wire 20 as shown in FIG. 1 . Then, except for the special length stator wires used for the phase connection in AC motors, all the wires required are simultaneously bent into the rotor or stator wires 24 ( FIG. 3 ) in the torsion jig 22 shown in FIG. 2 . After the twisting operation, the wire 24 remains in the clamp 22, which has sufficient depth so that the end of the wire 24 is still located in the cavity within the clamp. The term "chamber" as used here is used in a general sense and includes not only enclosures enclosed on all sides, but also grooves which are open on one side.

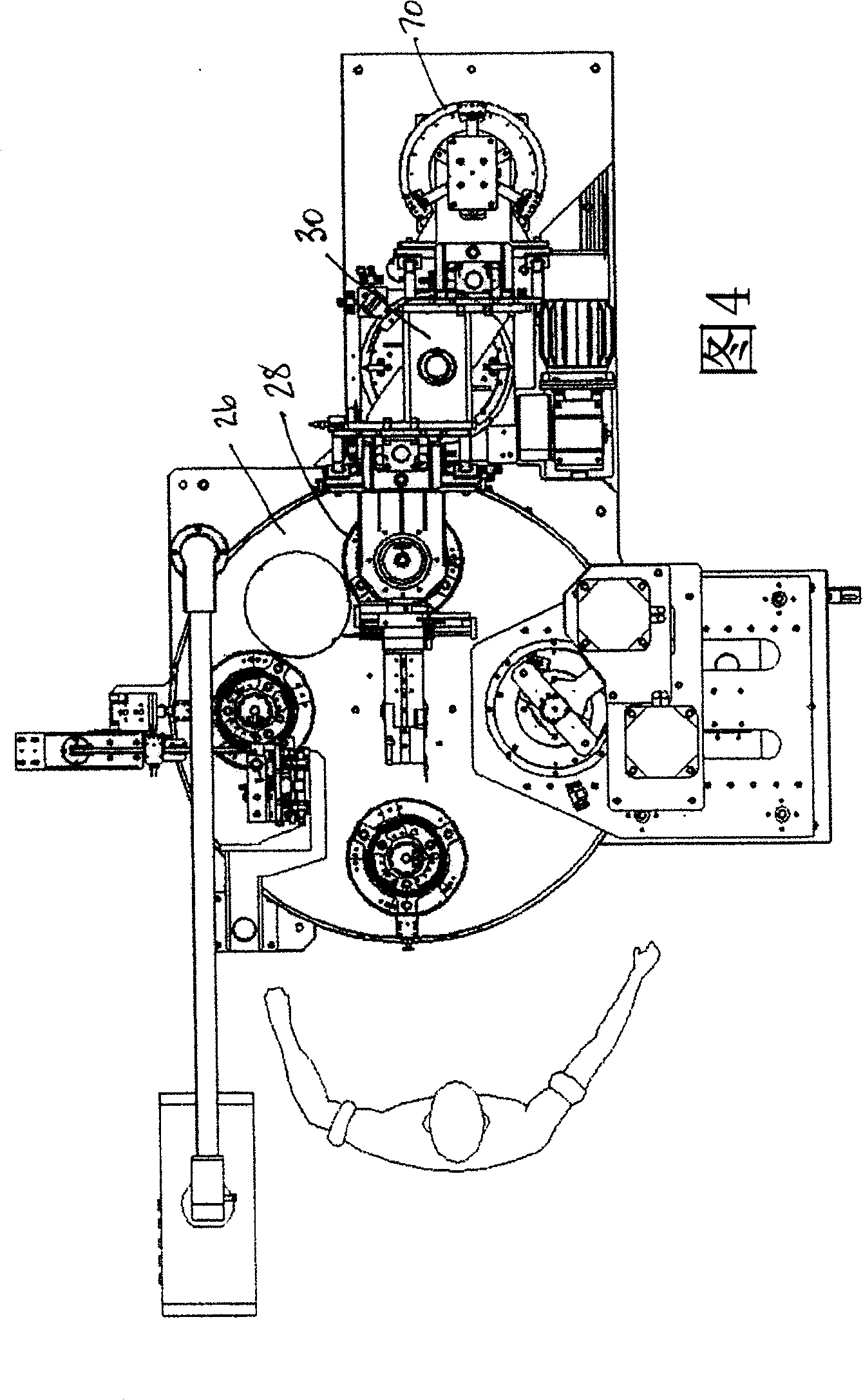

[0032] Figure 4 shows a top view of the entire system using the present invention. After the twisting operation, the table 26 is rotated so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com