Ultrasonic fuel injector

A fuel injector, ultrasonic technology, applied in the direction of low pressure fuel injection, low pressure fuel injection, fuel injection device, etc., can solve the problem of difficult to accommodate and operate valve components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

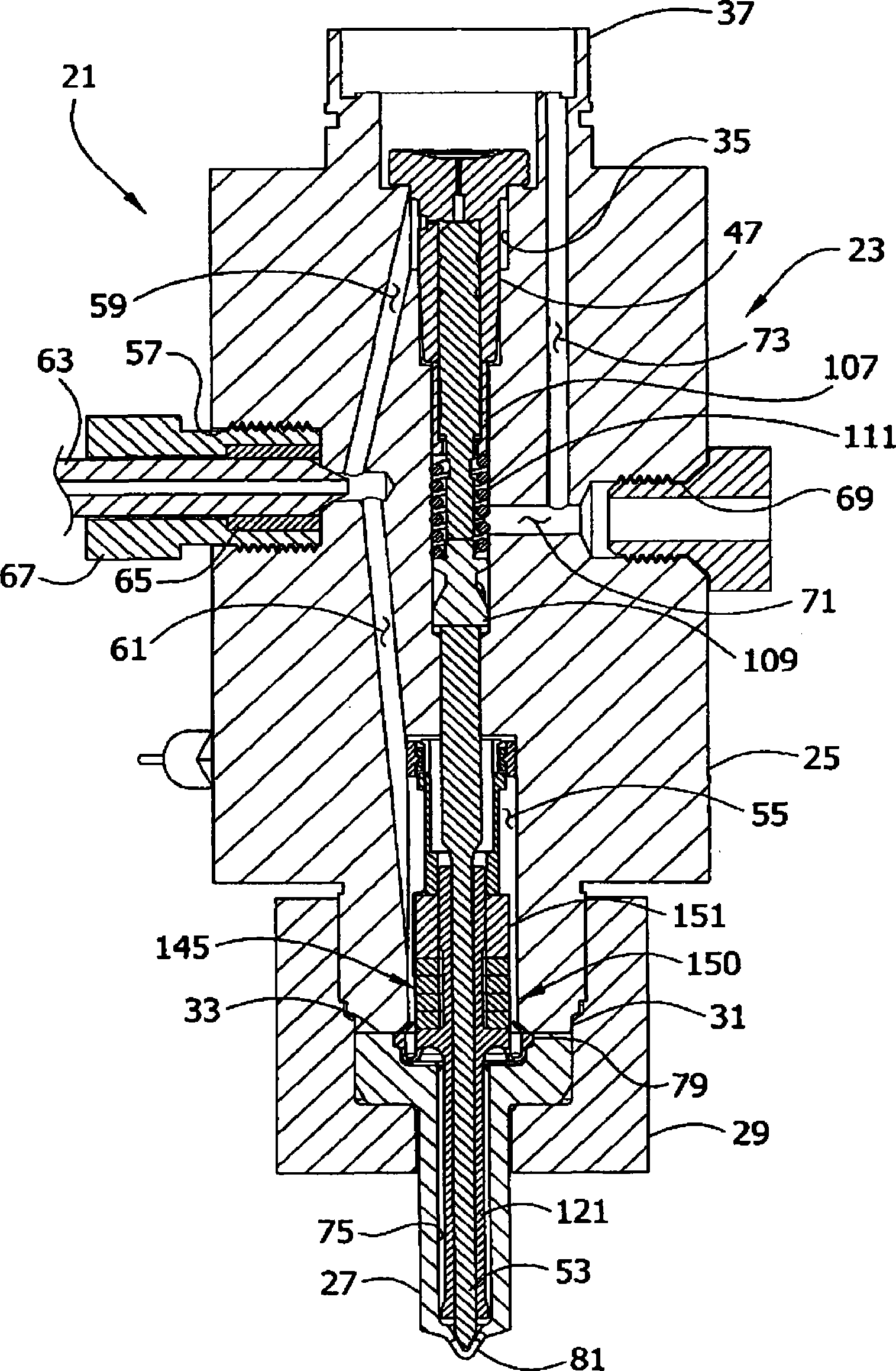

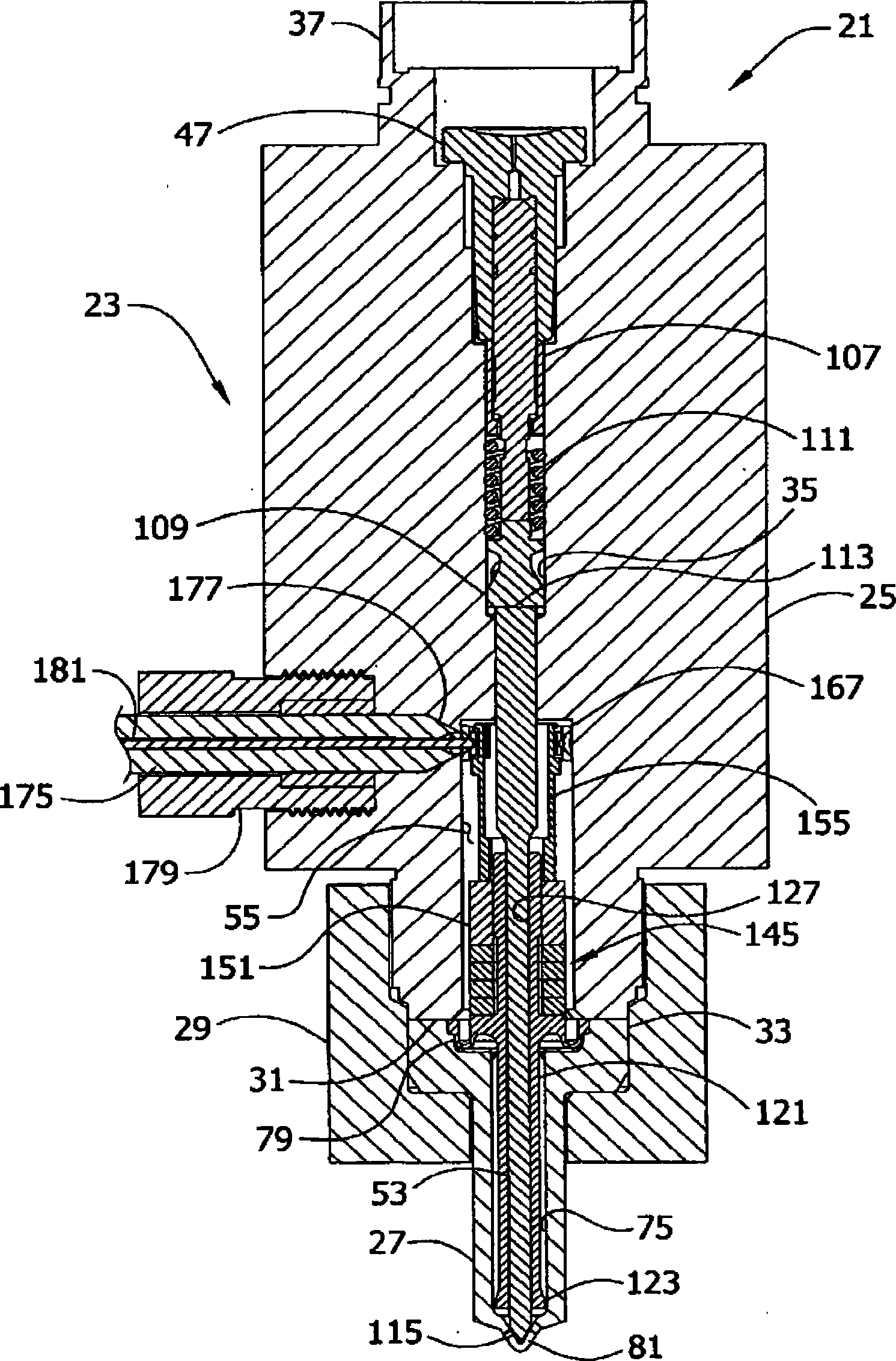

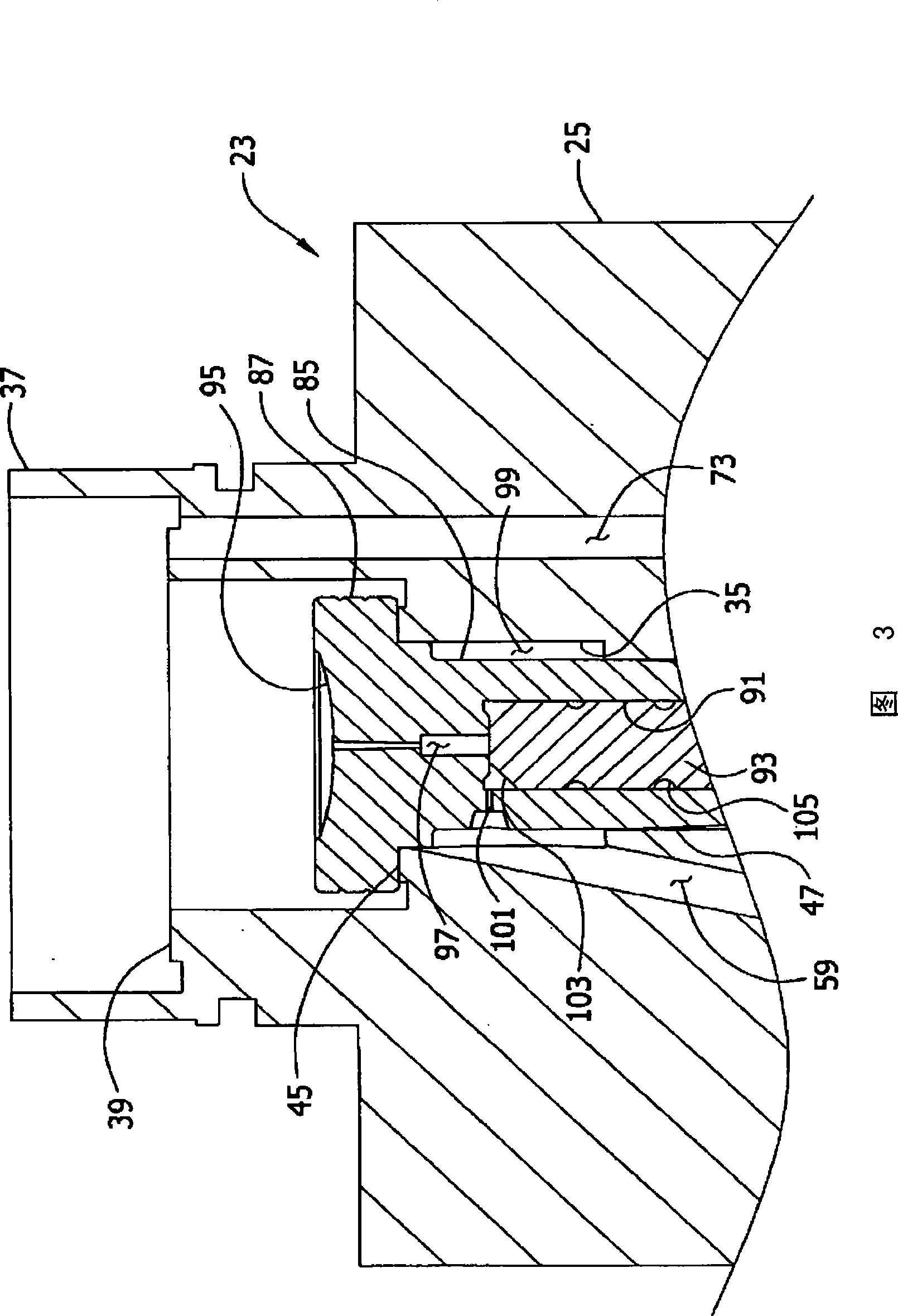

[0024] Referring now to the accompanying drawings, in particular figure 1 , generally designated 21, is one embodiment of an ultrasonic fuel injector for delivering fuel to an engine (not shown). The fuel injector can be used in land, air, sea vehicles, generators, and other devices using engines. In particular, the fuel injector is suitable for use with engines using diesel fuel. However, it should be understood that the term fuel as used herein means any combustible fuel used in the operation of the engine and is not limited to diesel.

[0025]Fuel injector 21 includes a housing generally indicated at 23 for receiving pressurized fuel from a fuel source (not shown) and delivering an atomized spray of fuel droplets to an engine, such as to a combustion chamber of the engine. In the illustrated embodiment, the housing 23 includes an elongated body 25, a nozzle 27 (sometimes referred to as a valve body) and a retaining member 29 (such as a nut) that holds the body, nozzle and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com