Fill level measuring device for determining and/or monitoring a fill level

A liquid level measurement device and a technology for fixing devices, which are applied in the direction of measuring devices, liquid/fluid solid measurement, liquid level indicators for physical variable measurement, etc., can solve problems such as unfavorable driving stack relaxation or load, and achieve thermal characteristic optimization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

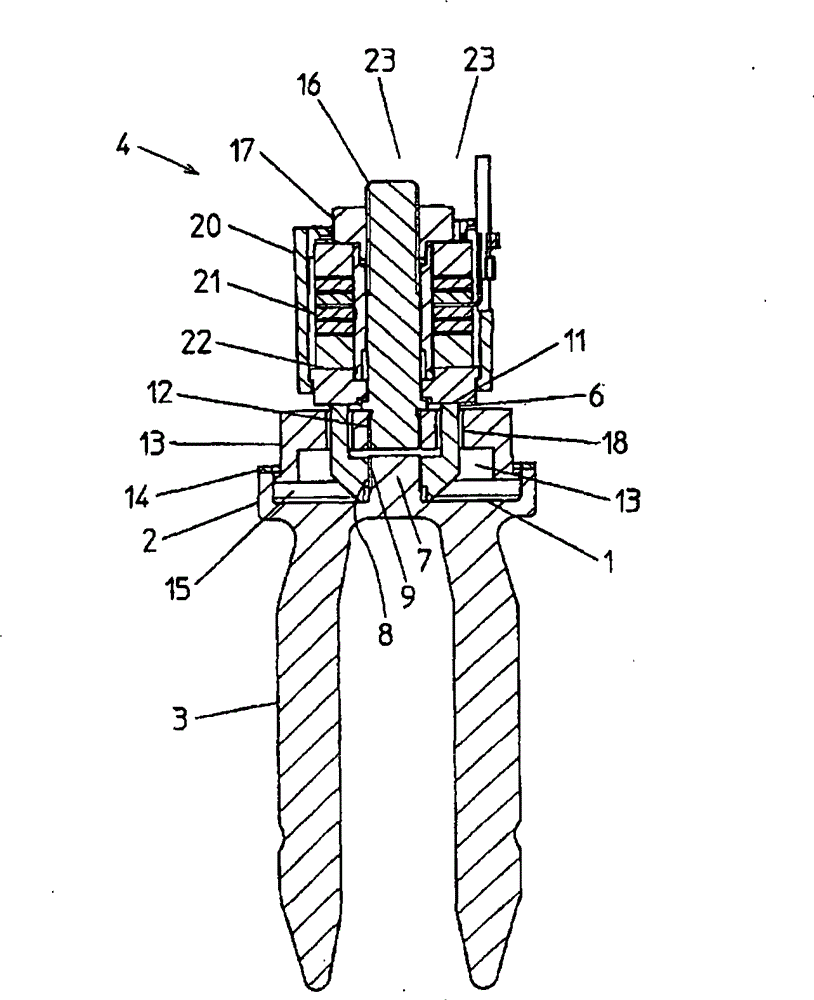

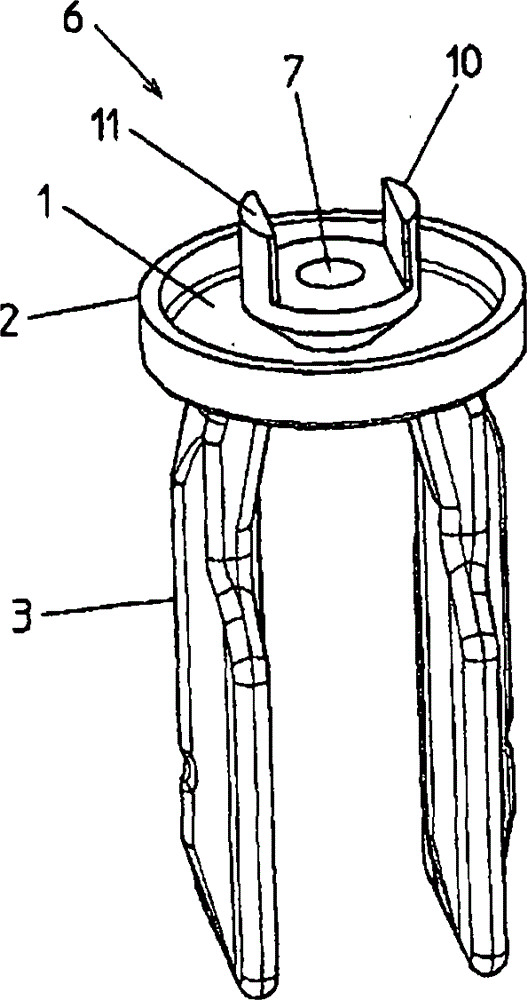

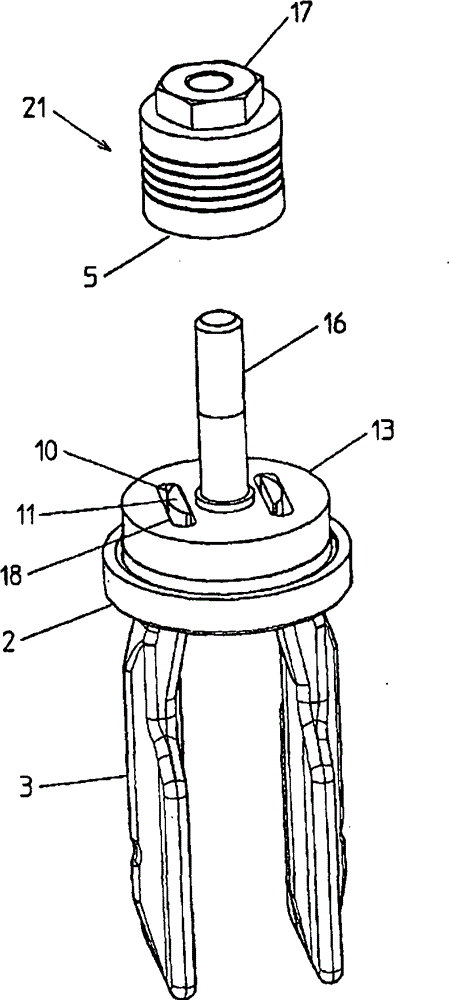

[0027] Figures 1 to 3An exemplary fill level measuring device or at least individual components of such a fill level measuring device for determining and / or monitoring a fill level, in particular in a container, are shown in different views.

[0028] Such a level measuring device consists in a manner known per se of a diaphragm 1 which can be fastened in a housing by means of its diaphragm rim 2 . The diaphragm 1 is surrounded here by a rigid diaphragm rim 2 , but at the same time the diaphragm 1 remains vibrateable. Diaphragm 1 has a vibrating body, for example in the form of a fork 3, towards the front, which serves as an antenna for transmitting vibrations of the diaphragm 1 to the surroundings of the front and simultaneously as a receiver of vibrations from the surroundings of the front for sending vibrations to the surroundings of the front. Diaphragm 1 passes. Arranged toward the rear of the membrane 1 is a drive 4 which clamps against the membrane 1 with a front driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com