Conicity measurement mechanism for circular copper pipe crystallizer

A technology of measuring devices and crystallizers, which is applied in the direction of measuring devices, instruments, etc., can solve problems such as difficulty and lack of detection methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

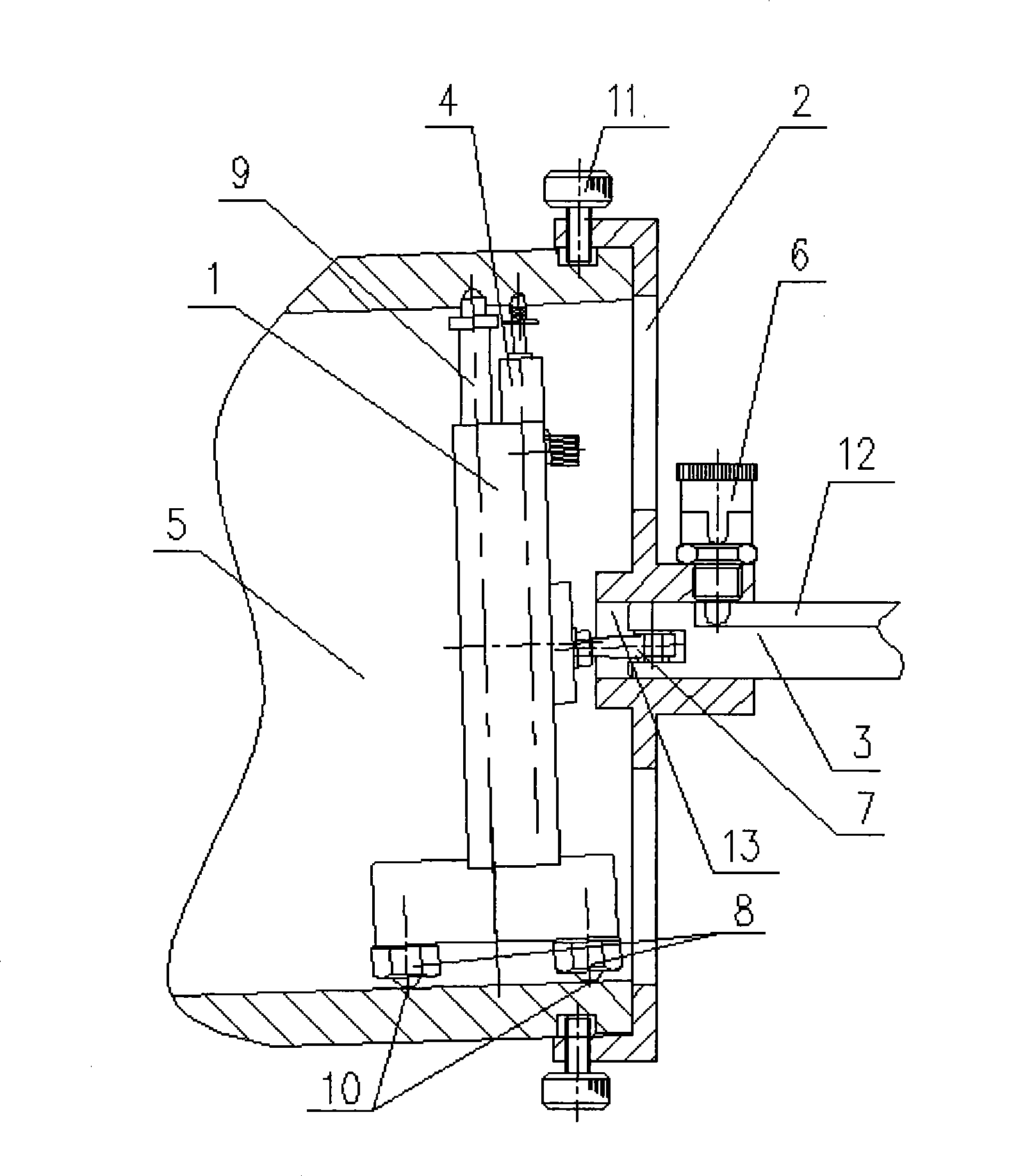

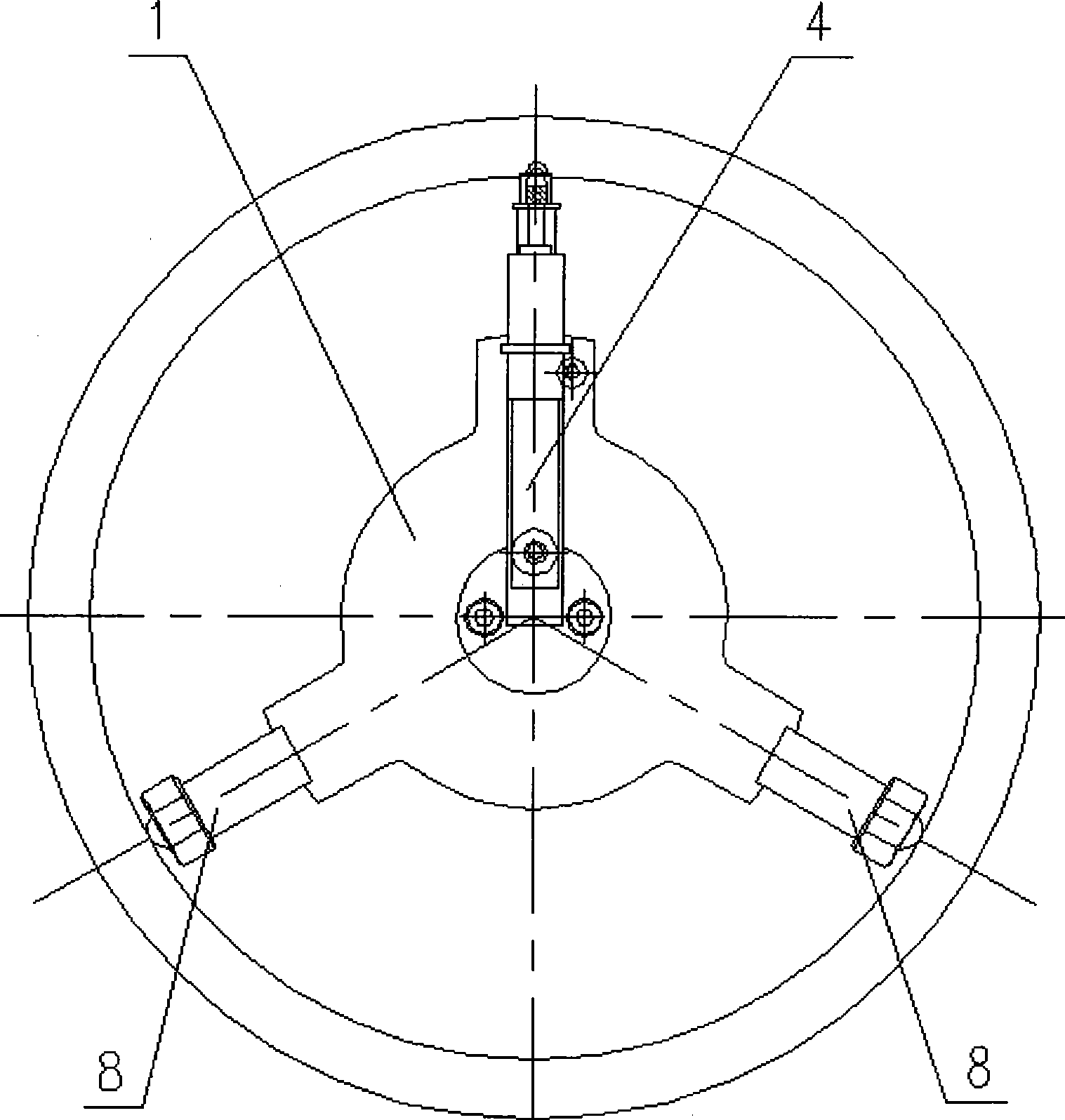

[0012] The taper measuring device of the circular copper tube crystallizer of the present invention is composed of two major systems of mechanical structure and data processing; it can be used for on-site measurement and special measurement room measurement. Among them, the detection instrument is the main body in the mechanical structure, see figure 1 , 2 As shown, it includes three major components: a detection body 1, a guide cover 2, and a feed push rod 3. The detection body 1 is supported in the inner cavity of the circular copper tube 5 by two fixed support rods 8 and one elastic support rod 9 (elastic support point), which is responsible for movement and detection in the inner cavity of the circular copper tube 5 . Between the two fixed support rods 8, the fixed support rods 8 and the elastic support rods 9 are arranged at equal angles. According to the rule that three points form a surface, they constitute a stable detection volume. In order to increase the stabilit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com