Multilayer ceramic electronic component and manufacturing method thereof

A technology of electronic parts, ceramics, applied in the field of laminated ceramic electronic parts and its manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

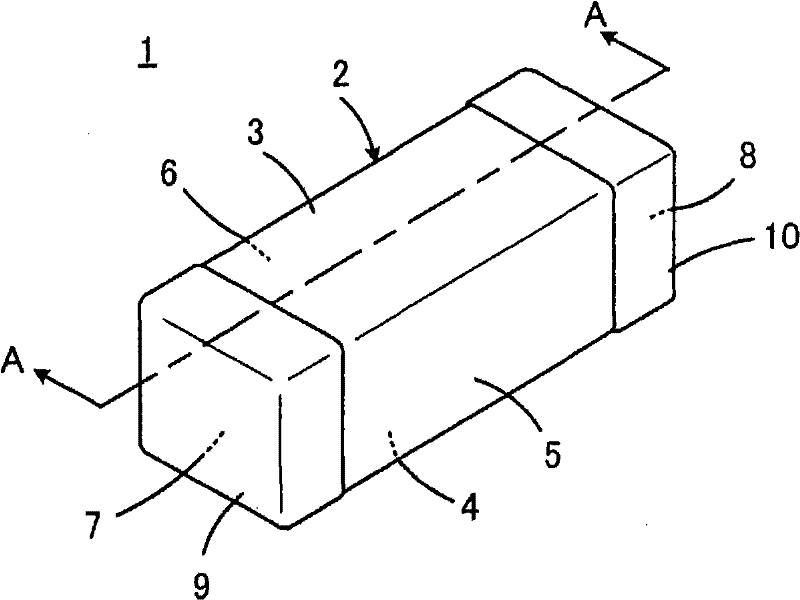

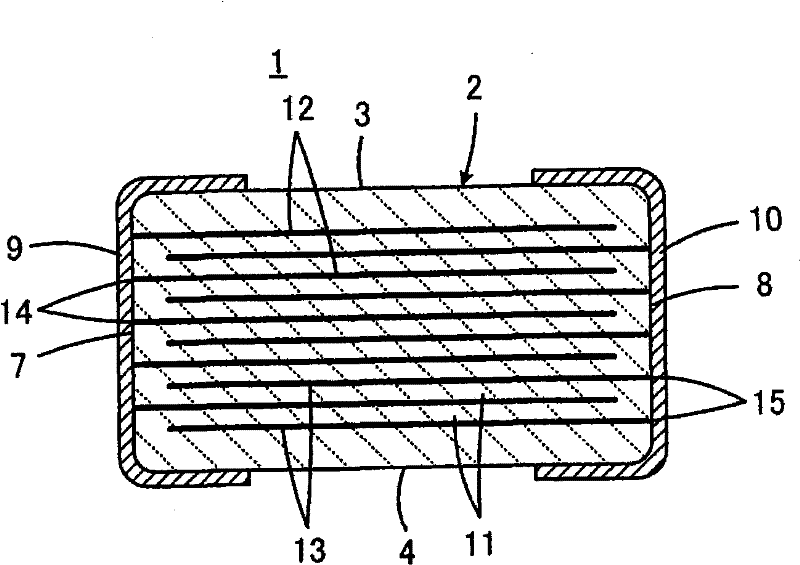

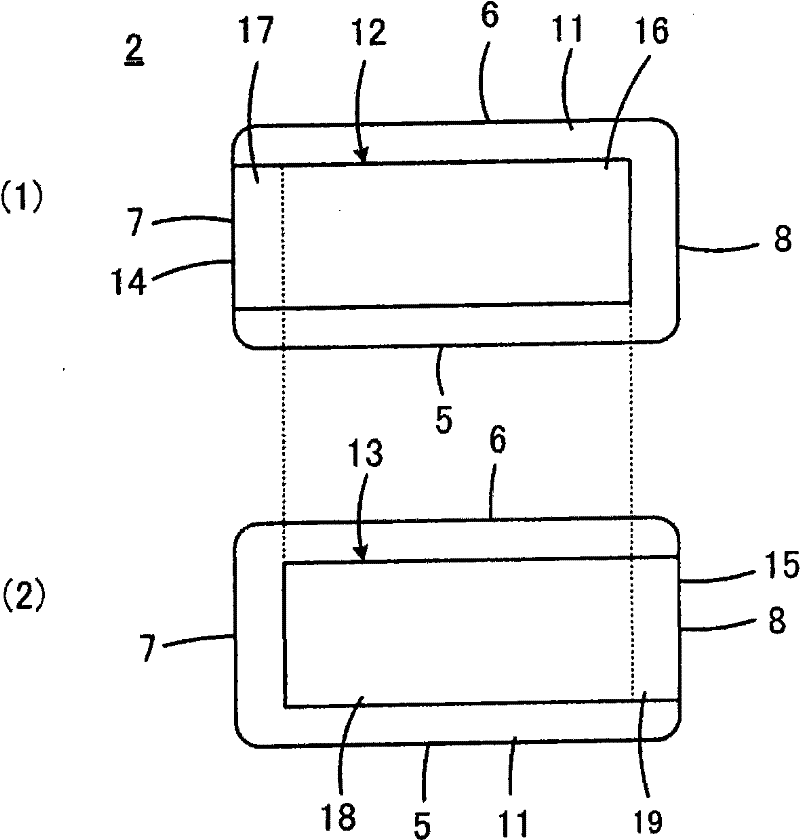

[0060] Figure 1 to Figure 4 It is used to explain the first embodiment of the present invention. here, figure 1 It is a perspective view showing a multilayer ceramic capacitor 1 as an example of a multilayer ceramic electronic component. figure 2 for along figure 1 A profile of the line A-A.

[0061] A multilayer ceramic capacitor 1 includes a ceramic raw material 2 . The ceramic raw material 2 has a cubic shape, and has mutually opposing first and second main surfaces 3 and 4 , and four side surfaces 5 to 8 connecting the first and second main surfaces 3 and 4 . In addition, in the following description, among the four side surfaces 5 to 8, the side surfaces 5 and 6 extending in the longitudinal direction of the main surfaces 3 and 4 are referred to as first and second side surfaces, respectively, and the side surfaces extending in the short direction are referred to as 7 and 8 are referred to as first and second end faces, respectively.

[0062] First and second ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com