Self-pressing stern shaft filler seal

A packing sealing and self-compression technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of troublesome operation, heavy workload, and difficulty in truly ensuring the stability and reliability of the sealing performance of the sealing device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

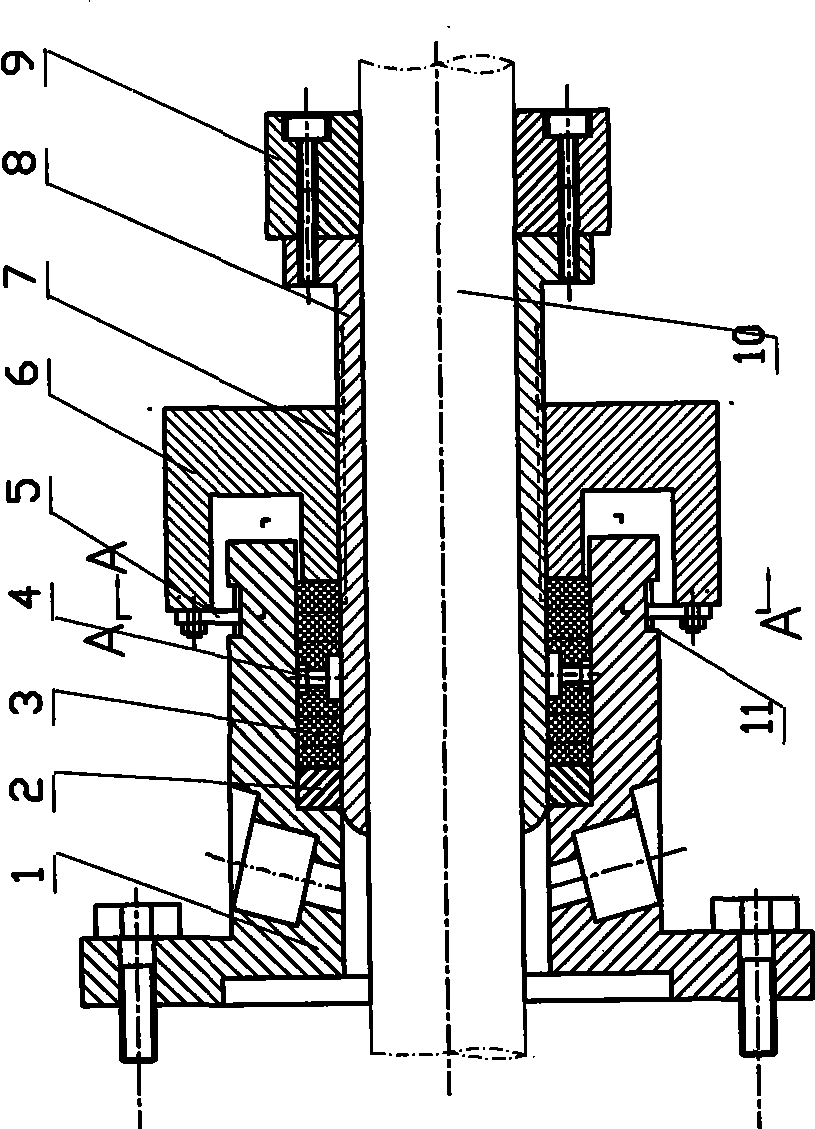

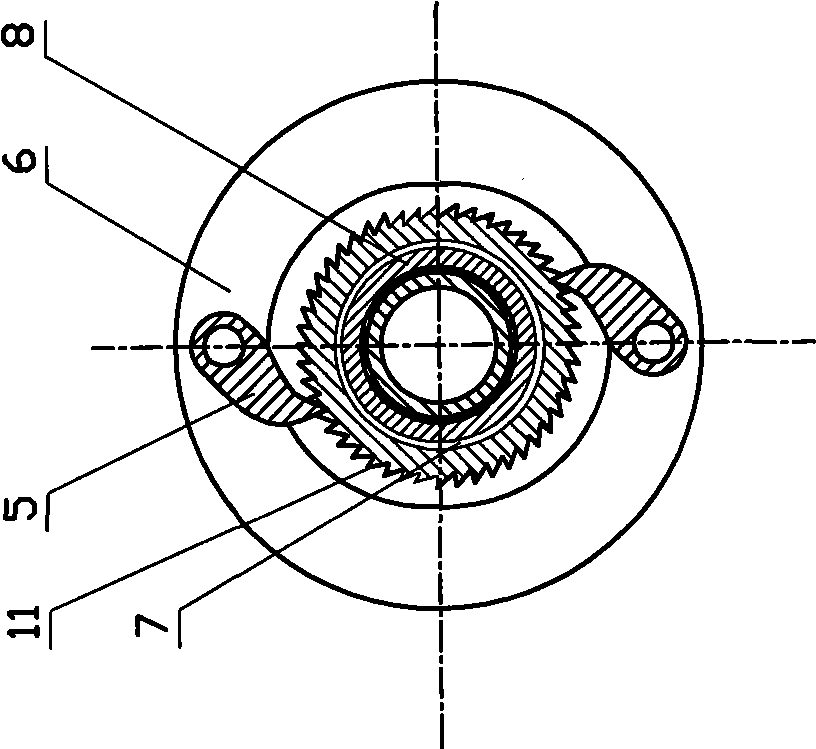

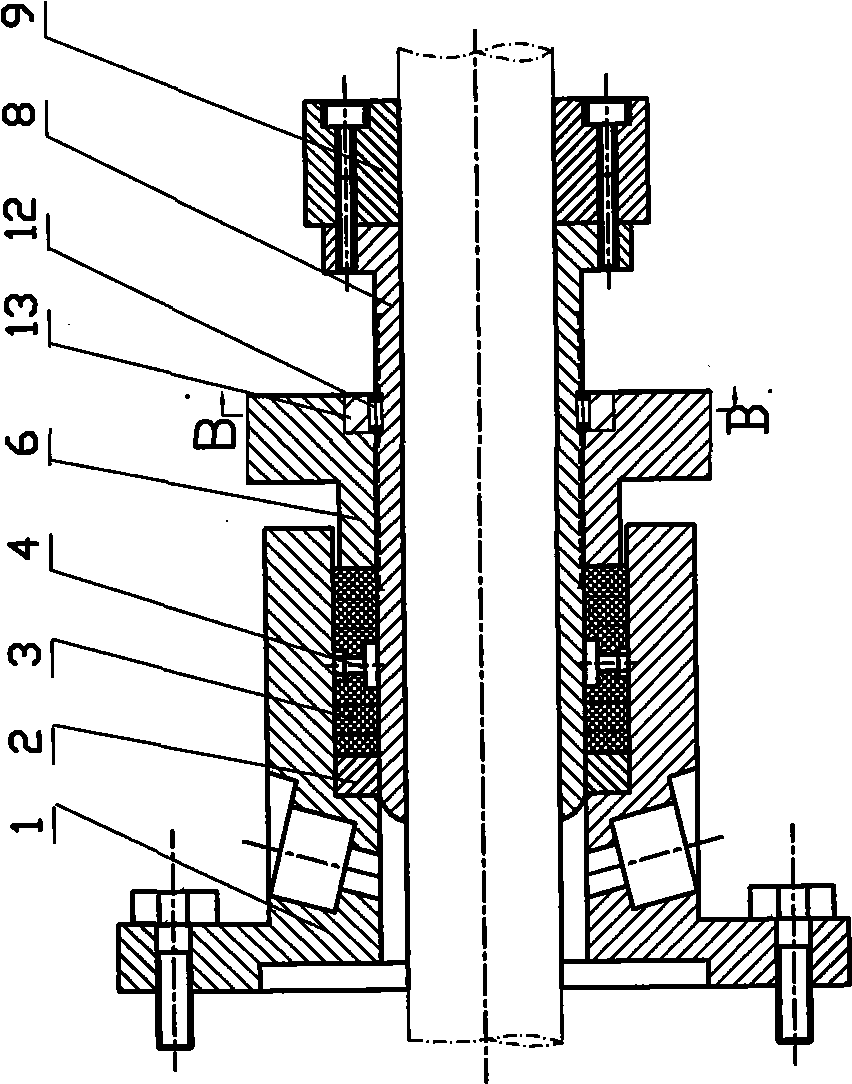

[0015] exist figure 1 , figure 2 In the shown self-compressing stern shaft packing seal structure, the clamping ring 9 of the split structure is clamped and fixed on the stern shaft 10, and rotates together with the stern shaft 10; the shaft sleeve 8 is tightly sleeved on the stern shaft 10 And it is fixedly connected with the clamp collar 9 by bolts, and an external thread is arranged on the outer cylindrical surface of the axle sleeve 8 . The packing gland 6 adopts a disc-shaped structure, and its center is provided with a threaded hole. The packing gland 6 is screwed to the external thread position of the shaft sleeve 8 through the threaded hole. The threaded hole of the packing gland 6 and the external thread on the shaft sleeve 8 The thread forms the connecting thread 7 . The sealing device body 1 is empty sleeved on the stern shaft 10. The sealing device body 1, the shaft sleeve 8 and the packing gland 6 form a packing cavity, and the packing cavity is filled with sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com