Paint shop and corresponding method of operation

A painting and equipment technology, applied in the direction of spraying device, etc., can solve the problems of complex rotating station, time-consuming, reducing the overall length of the dryer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

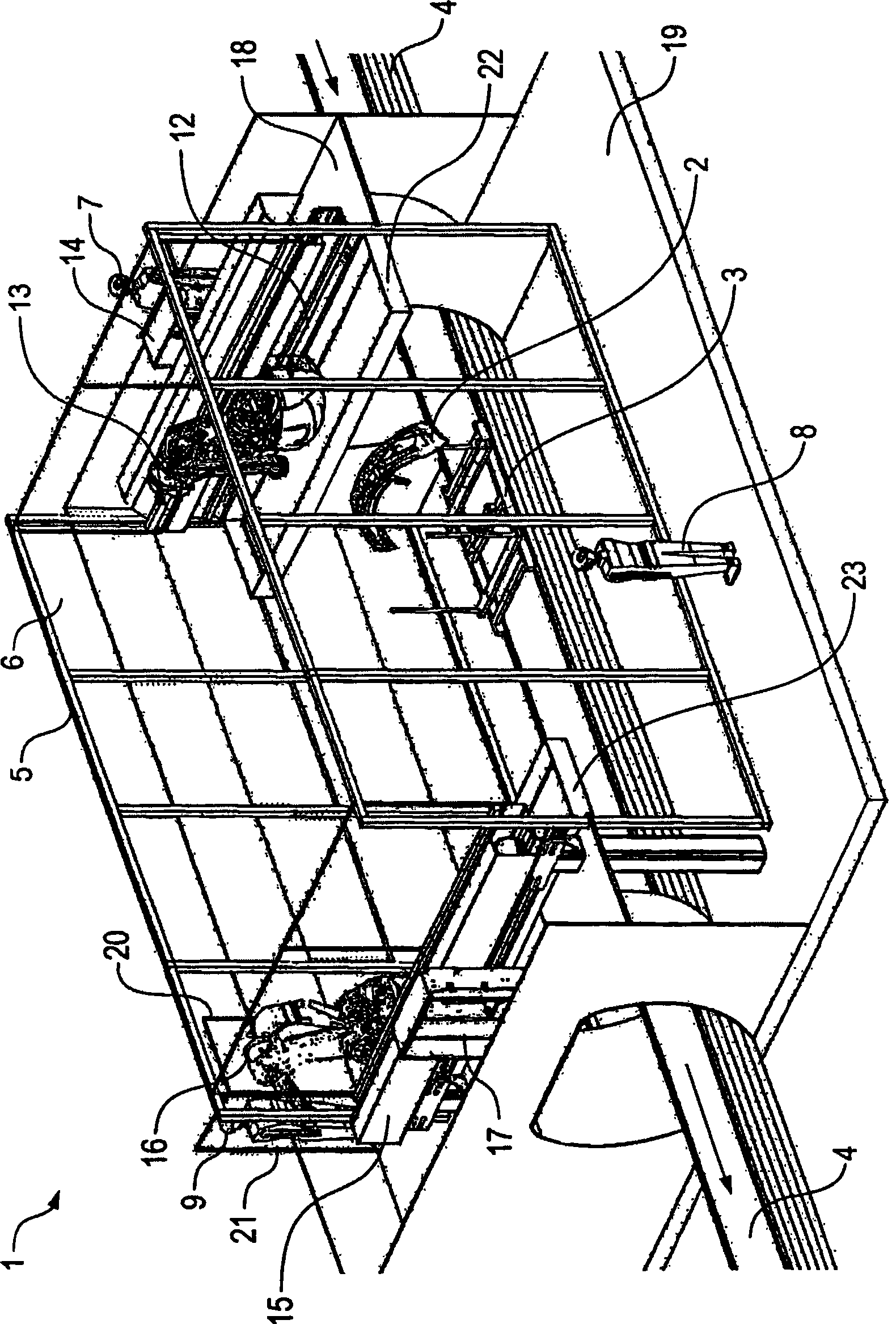

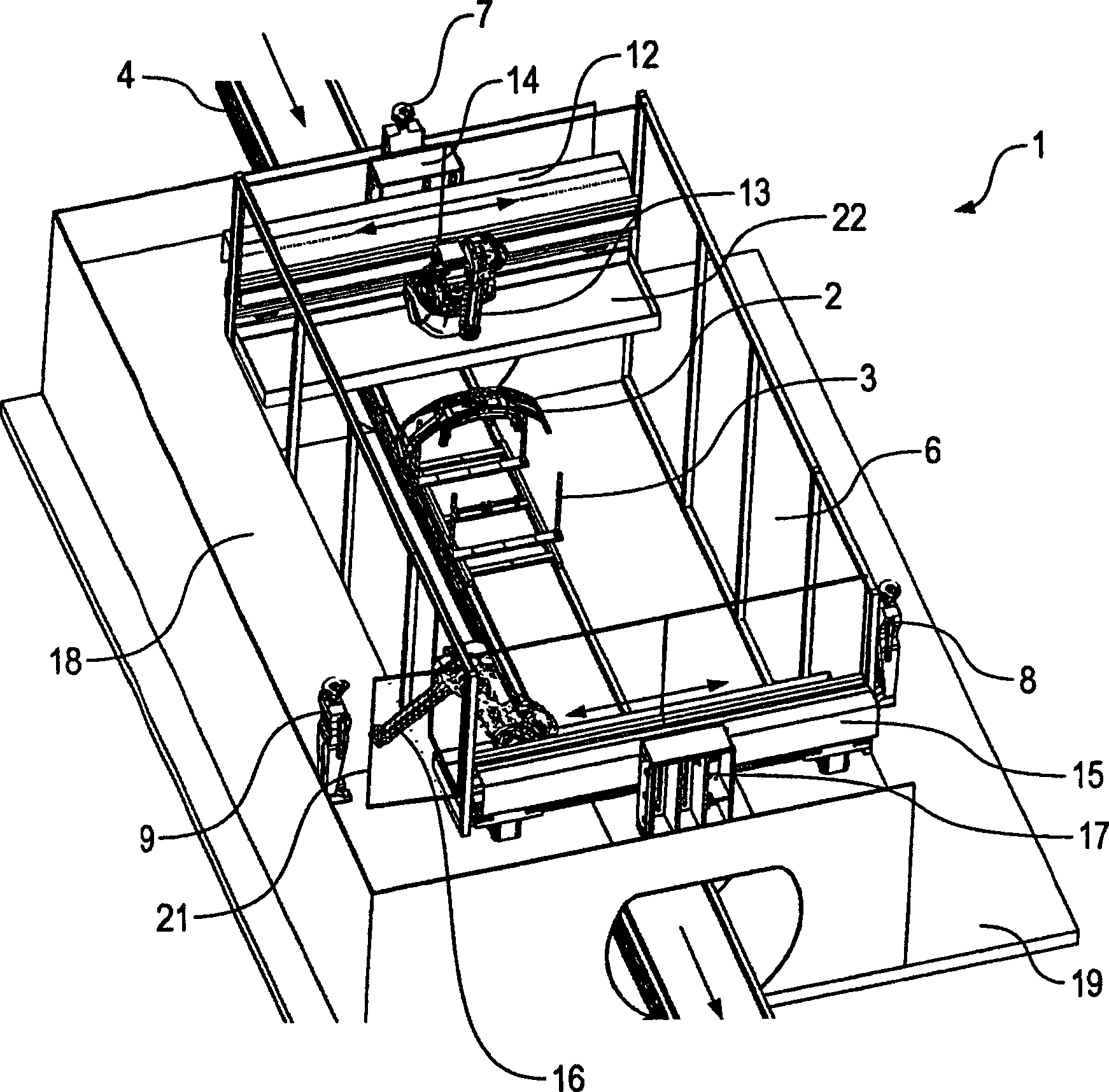

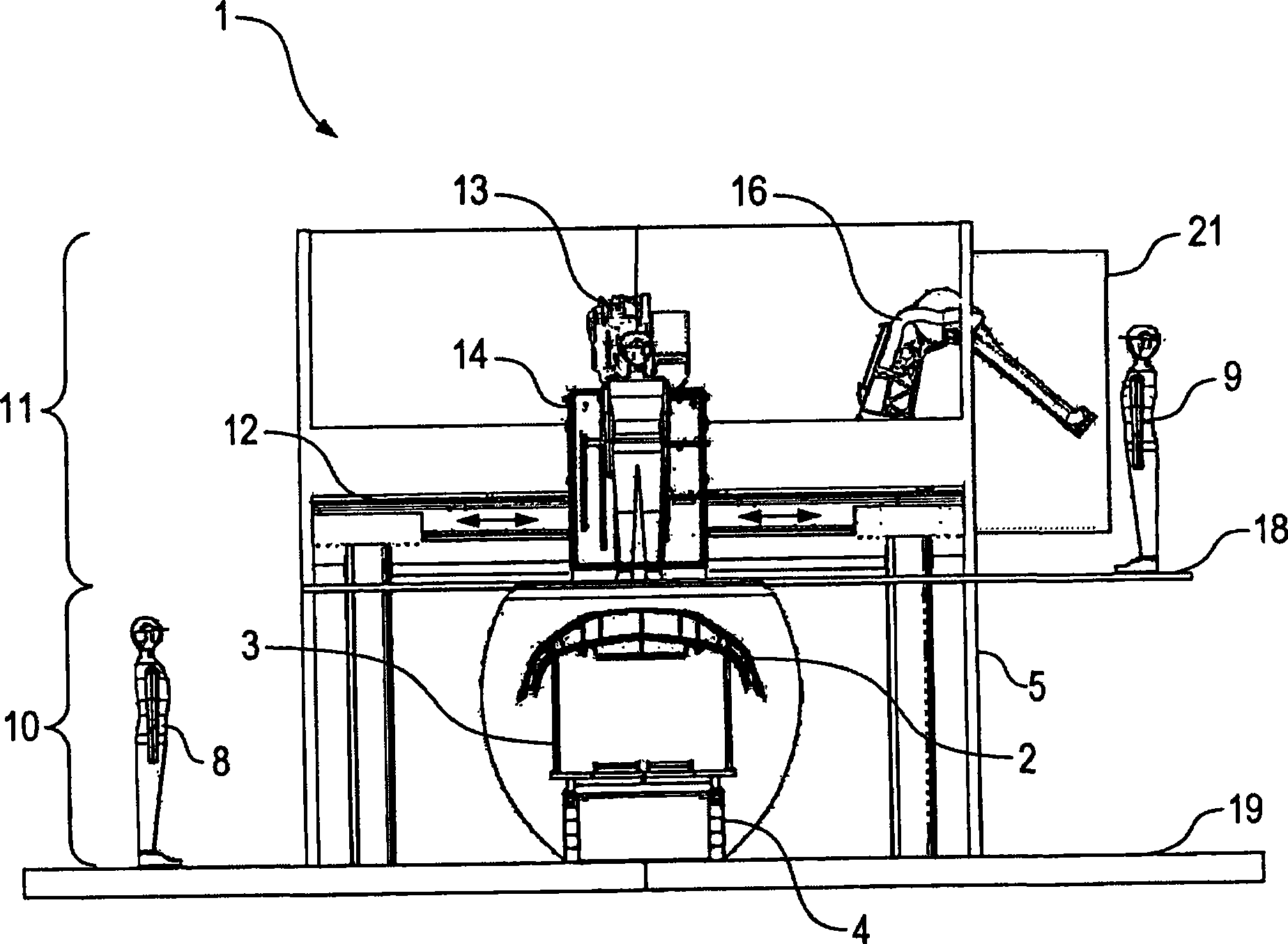

[0044] The figures show a preferred embodiment of the painting cabin 1 according to the invention for painting a motor vehicle bumper 2, wherein the motor vehicle bumper 2 is located on a slide rail 3 along a transport path 4 along the direction indicated by the arrow. Directions are conveyed through the paint cabin 1.

[0045] Additional processing stations (for example dryers) can be located in the direction of transport before and after the painting cabin 1 , but are not shown here for reasons of clarity.

[0046] The painting cabin 1 is provided as a clean room and has a frame 5 with continuous window panels 6 on all sides. Firstly, this offers the advantage that the painting process taking place in the painting booth 1 can be observed from the outside by operators 7 to 9 . Secondly, the continuous window arrangement enables a clean room, since the painting cabin 1 has no openings through which dust can enter the painting cabin 1 .

[0047] as image 3 Specifically show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com