Electric power transformer field calibration vehicle

A power transformer and on-site calibration technology, which is applied to instruments, motor vehicles, and object transport vehicles, can solve problems such as time-consuming, labor-intensive, low efficiency, and economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiment of the present invention will be described in detail below in conjunction with accompanying drawing:

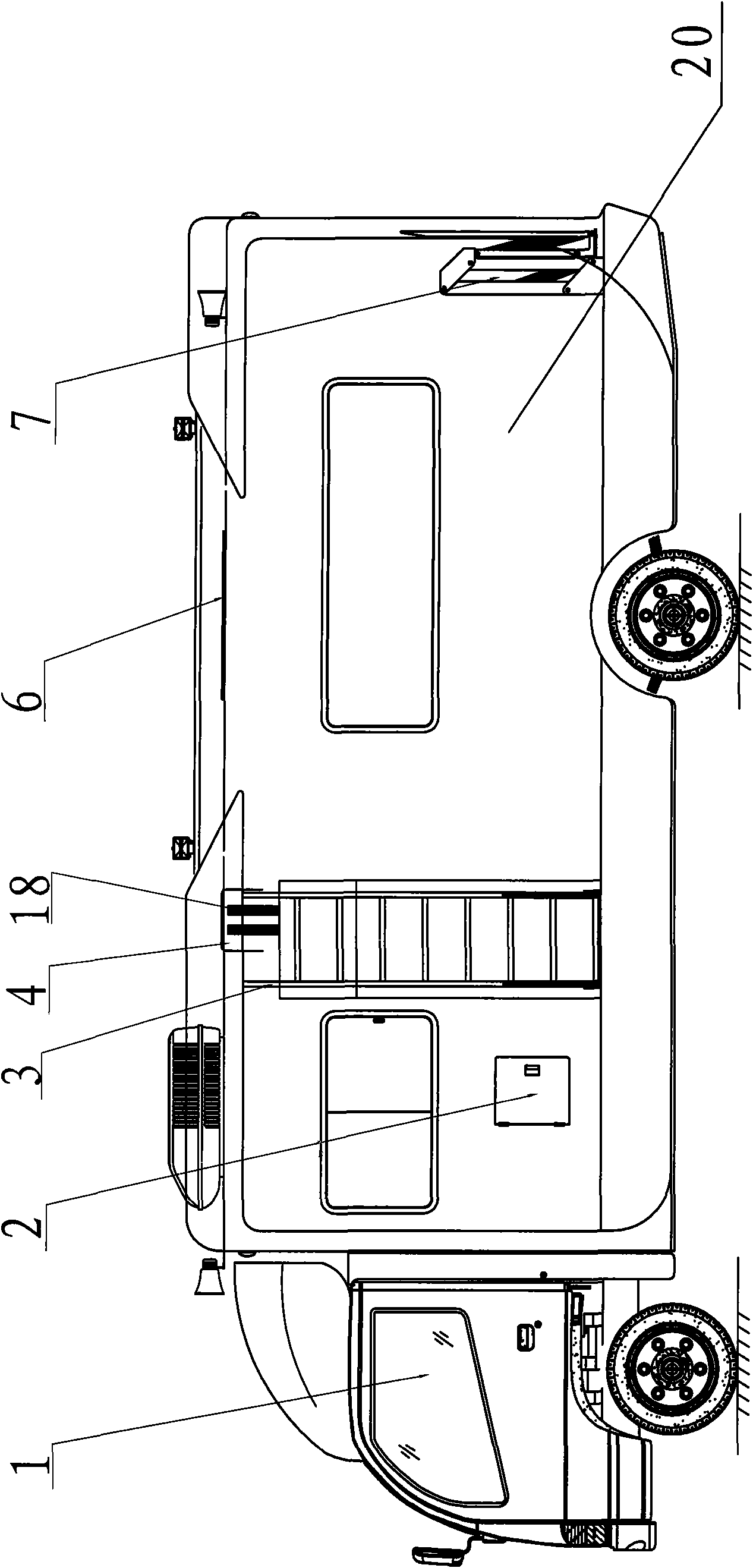

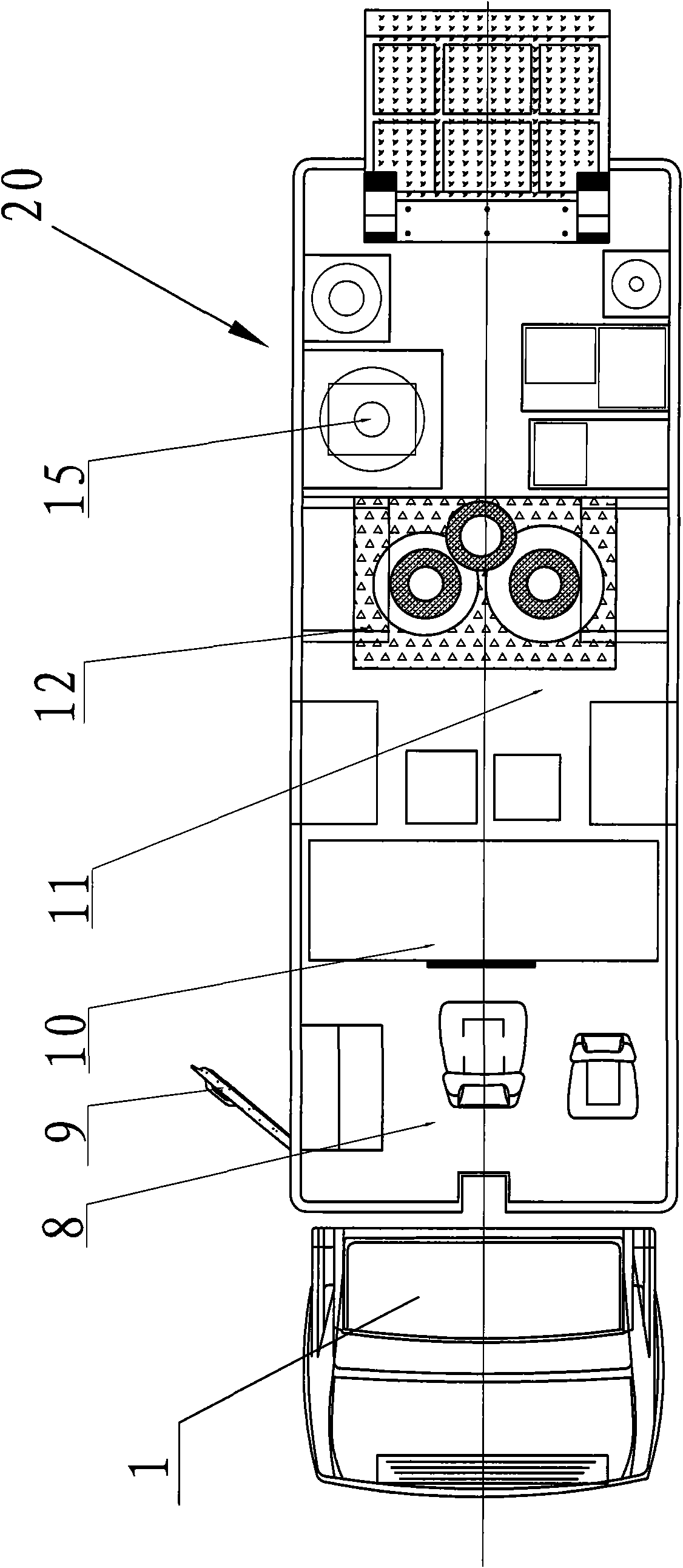

[0020] figure 1 and figure 2 Shown is a schematic diagram of a power transformer on-site calibration vehicle implemented by the present invention. Its main body is a special vehicle. The vehicle includes a driver's cabin 1 and a compartment 20. There is a door at the rear, through which the equipment can be loaded and unloaded.

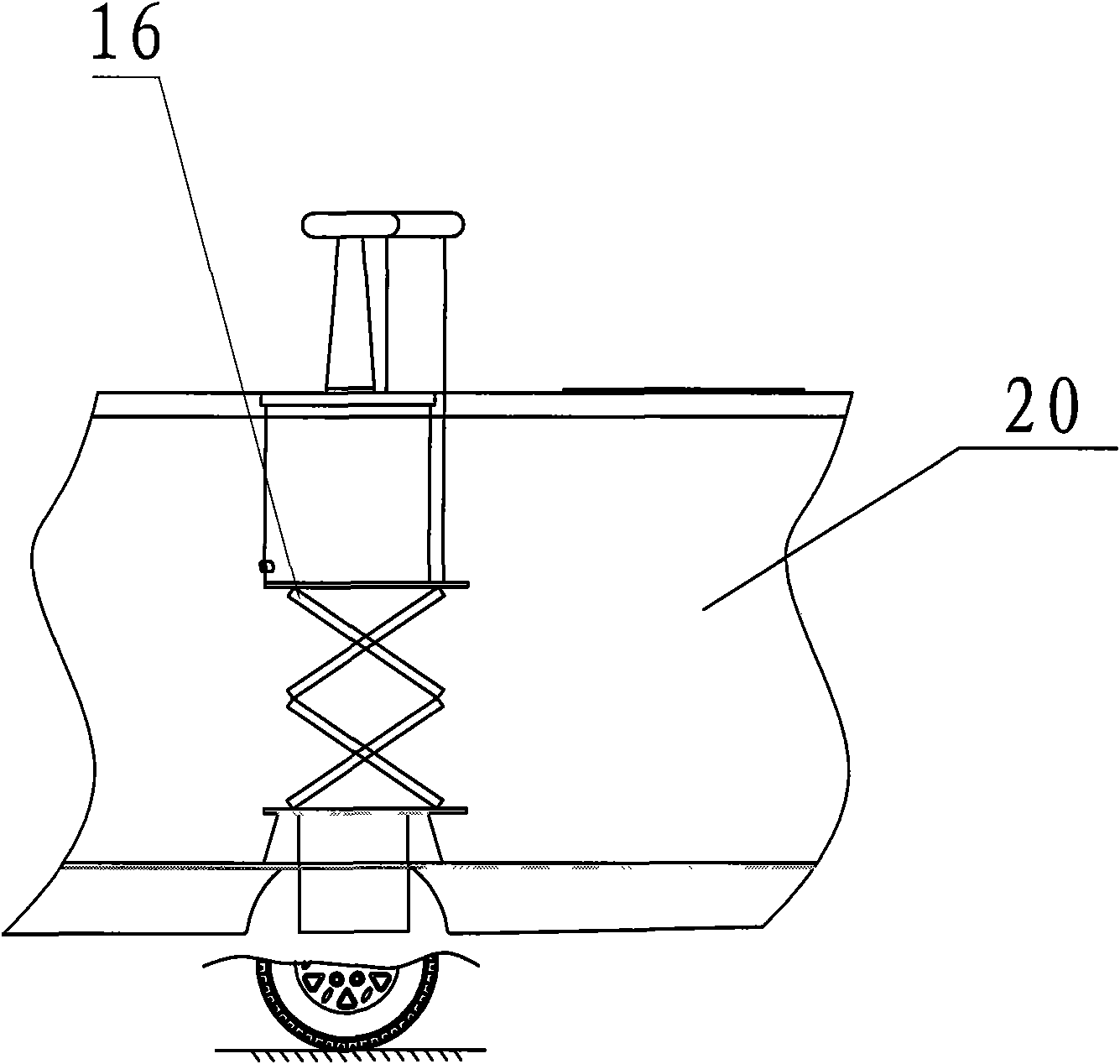

[0021] The space of the carriage 20 can be divided into the control room 8 at the front end and the equipment cabin 11 located at the rear of the control room 8. The control room 8 and the equipment cabin 11 are separated by the integral frame 10 arranged therebetween, in order to facilitate observation and communication , A window is also arranged between the control room 8 and the equipment cabin 11, and at the same time, the control room 8 is provided with a side door 9, so that the staff can go up and down the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com