Zero-clearance bolted joint

A technology of bolted joints, bolts, applied in the direction of screws, connecting members, shrinkage connections, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] While the invention is susceptible of embodiments in different forms, with respect to the embodiments of the invention shown in the drawings and described in detail herein, it should be understood that the description herein is to be considered as illustrative of the principles of the invention and that It is not intended to limit the invention to the embodiments shown and described herein.

[0025] The present invention relates to a zero-backlash bolting joint that can be used, for example, as a method of fastening a differential case to a ring gear that is not critical of alignment and minimizes multiple passes under load on the ring gear. Gear slippage while cycling.

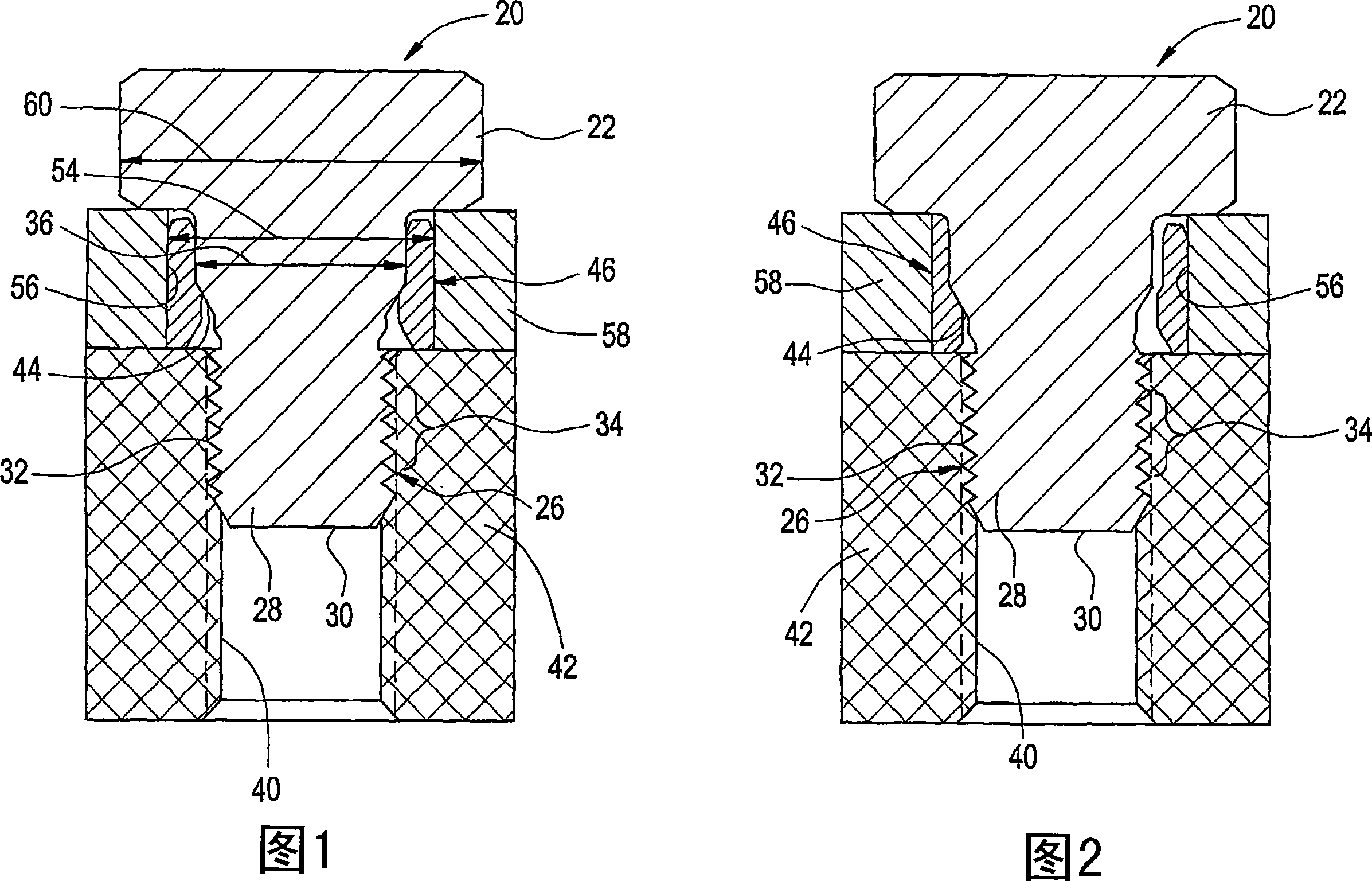

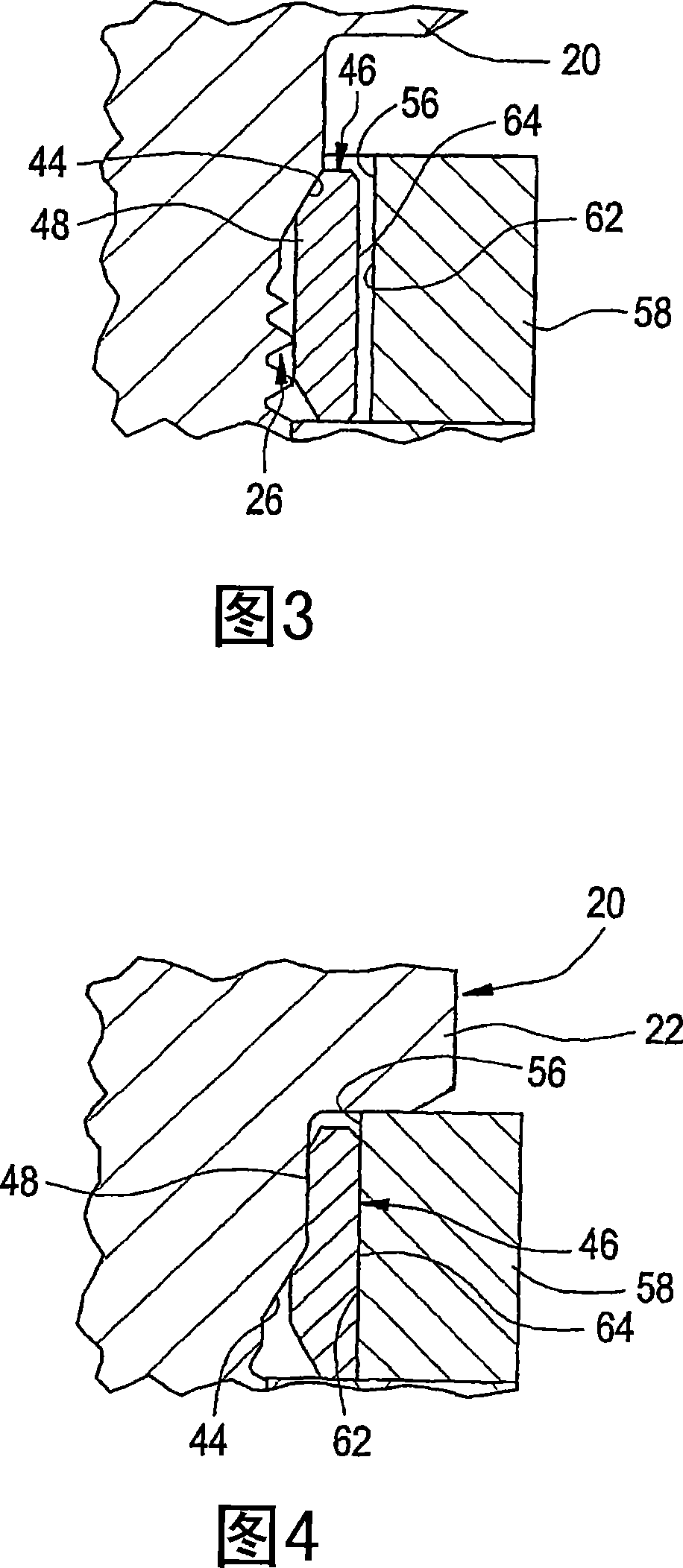

[0026] Such as figure 1 and figure 2 As shown, the bolted joint includes a bolt 20 having a head 22, which preferably has Figure 7 The hexagonal profile 24 is shown. Of course, the head 22 can also have other contours than hexagonal. Near the opposite end 30 of the bolt 20 , the threaded portion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com