Method for adjusting magenta pigment colour difference and product thereof

A magenta and pigment ink technology, applied in the field of adjusting the color difference of magenta pigments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

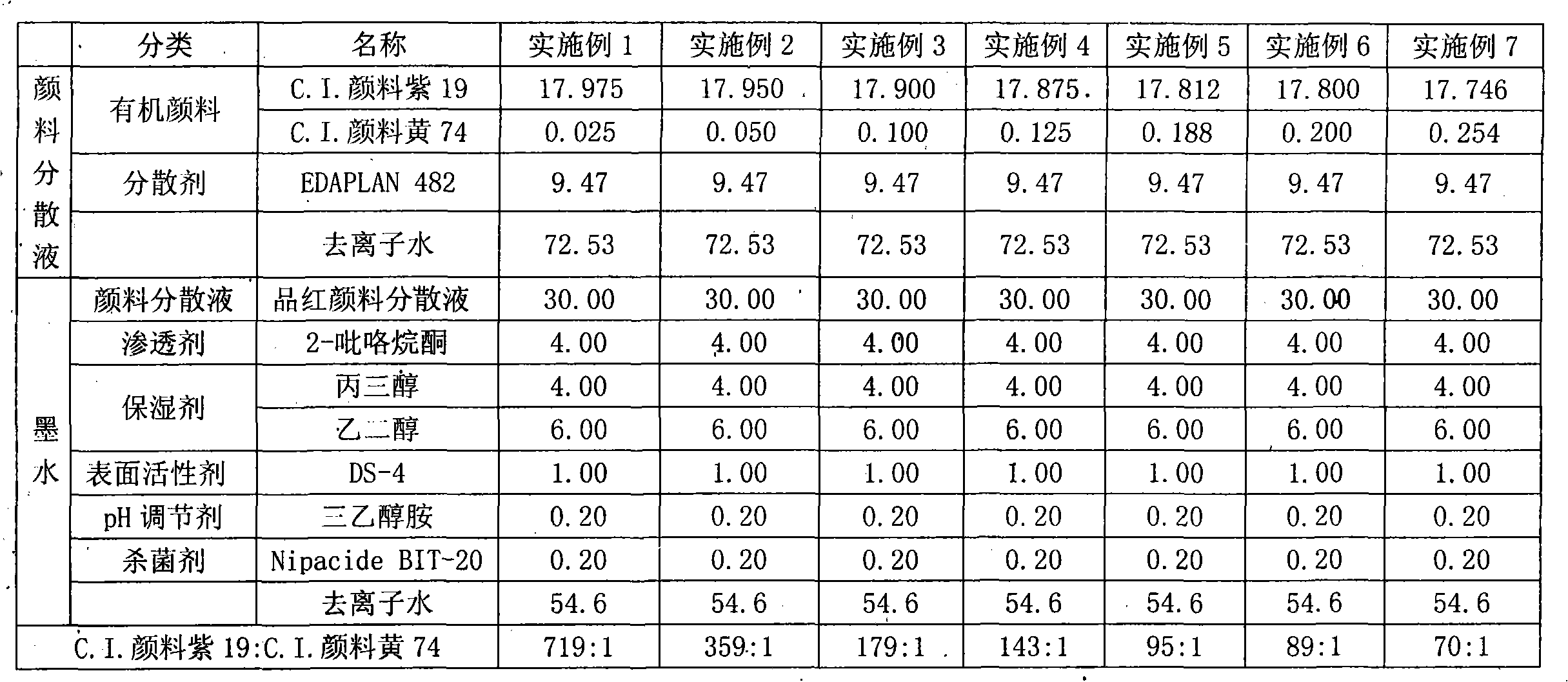

[0033] Embodiment 1: a method for adjusting the color difference of magenta pigment (the ratio of C.I. Pigment Violet 19 and C.I. Pigment Yellow 74 is 719: 1) and its products and applications:

[0034] With the C.I. pigment purple 19 of 17.975 parts of DIC companies, the C.I. pigment yellow 74 of 0.025 parts of Ciba companies, the dispersant EDAPLAN 482 of 9.470 parts of Ming Ling company (MUNZING), its active ingredient content 85.5%, 72.530 parts of deionized water with high-speed shears Mix with a stirrer for 1 hour until uniform to obtain a shear dispersion, and then grind 300 g of the shear dispersion in a 0.14 L grinder for 2 hours to obtain a magenta pigment dispersion. The ratio of C.I. Pigment Violet 19 and C.I. Pigment Yellow 74 is 719:1; select 30 parts of magenta pigment dispersion prepared in this example, 4 parts of 2-pyrrolidone as penetrating agent, 4 parts of glycerol and 6 parts of ethyl alcohol as humectant Glycol, surfactant selects 1 part of DS-4 of Rhodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com