Device for conveying small sheet workpieces one by one

A technology of small workpieces and flakes, applied in the field of automatic assembly devices, can solve the problems of low assembly efficiency, high fault maintenance rate, and low assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

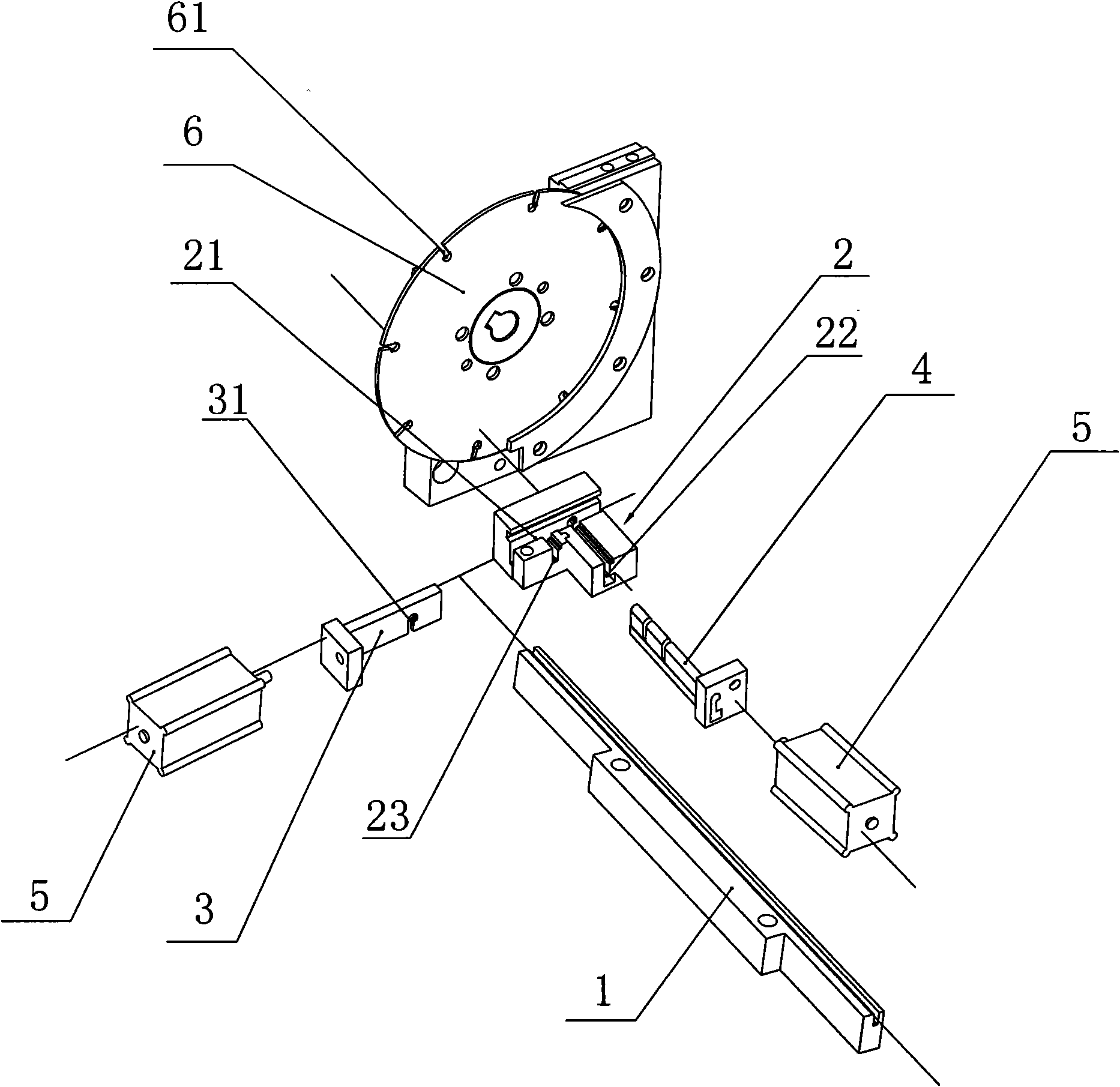

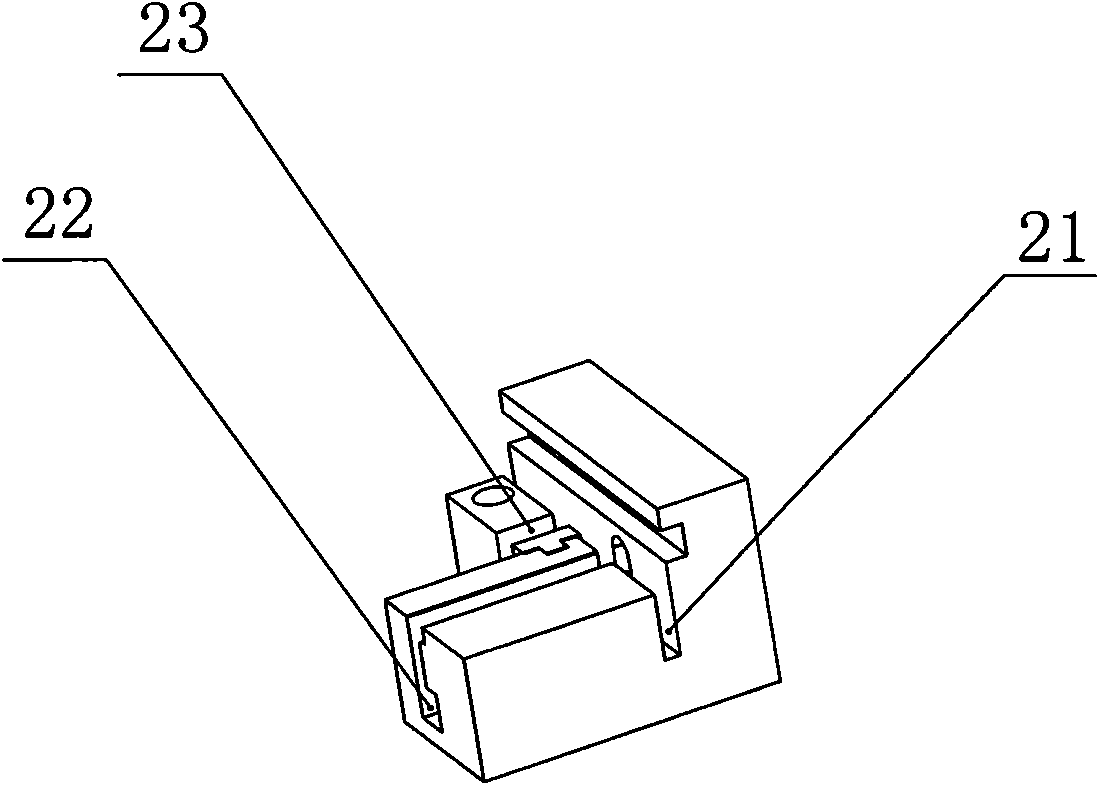

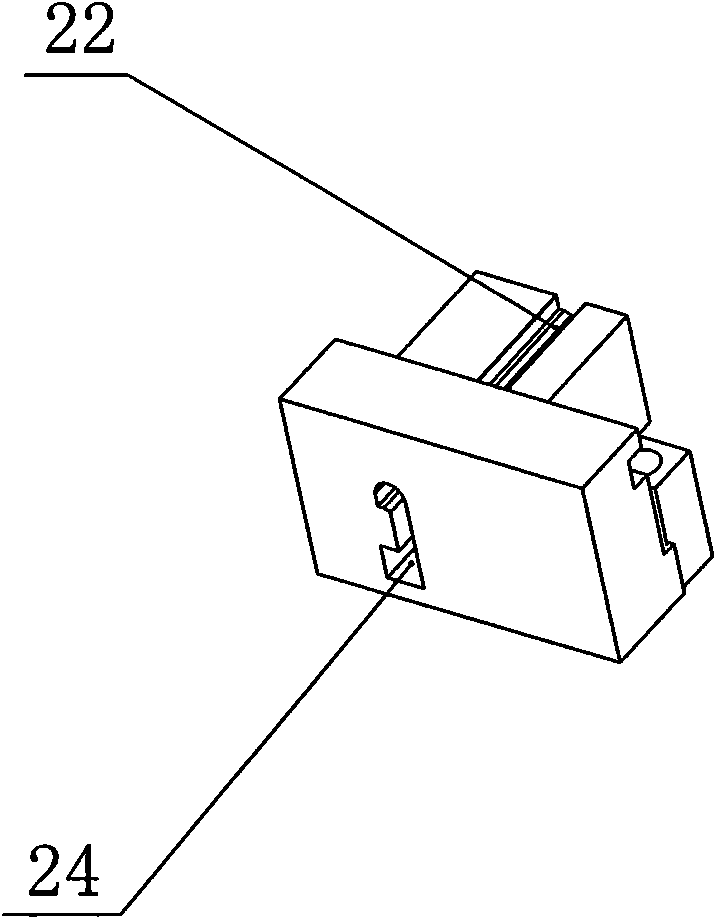

[0019] like Figure 1-3 The specific embodiment of the present invention described above includes a transport guide rail 1, a support seat 2, a first transport member 3, a second transport member 4, and a power mechanism. The power mechanism described in this embodiment is preferably a cylinder 5, The outer ends of the first transport member 3 and the second transport member 4 are connected with the cylinder 5 to form a linkage cooperation. The support seat 2 is provided with a through support seat 2 and is connected with the first transport member 3 and the second transport member. The first transport member sliding guide groove 21 and the second transport member sliding guide groove 22 cooperating with each other, the first transport member sliding guide groove 21 and the second transport member sliding guide groove 22 are perpendicular to each other Intersecting arrangement, the groove wall of the first conveying member sliding guide groove 21 is provided with an inlet port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com