Light source packaging structure

A packaging structure and light source technology, applied in the direction of light source, electric light source, point light source, etc., can solve problems such as not being as expected, and the device is not popular

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] In order to have a further understanding and understanding of the characteristics, purpose and functions of the present invention, the relevant structure and design concept of the system of the present invention are described below, and the detailed statements are as follows:

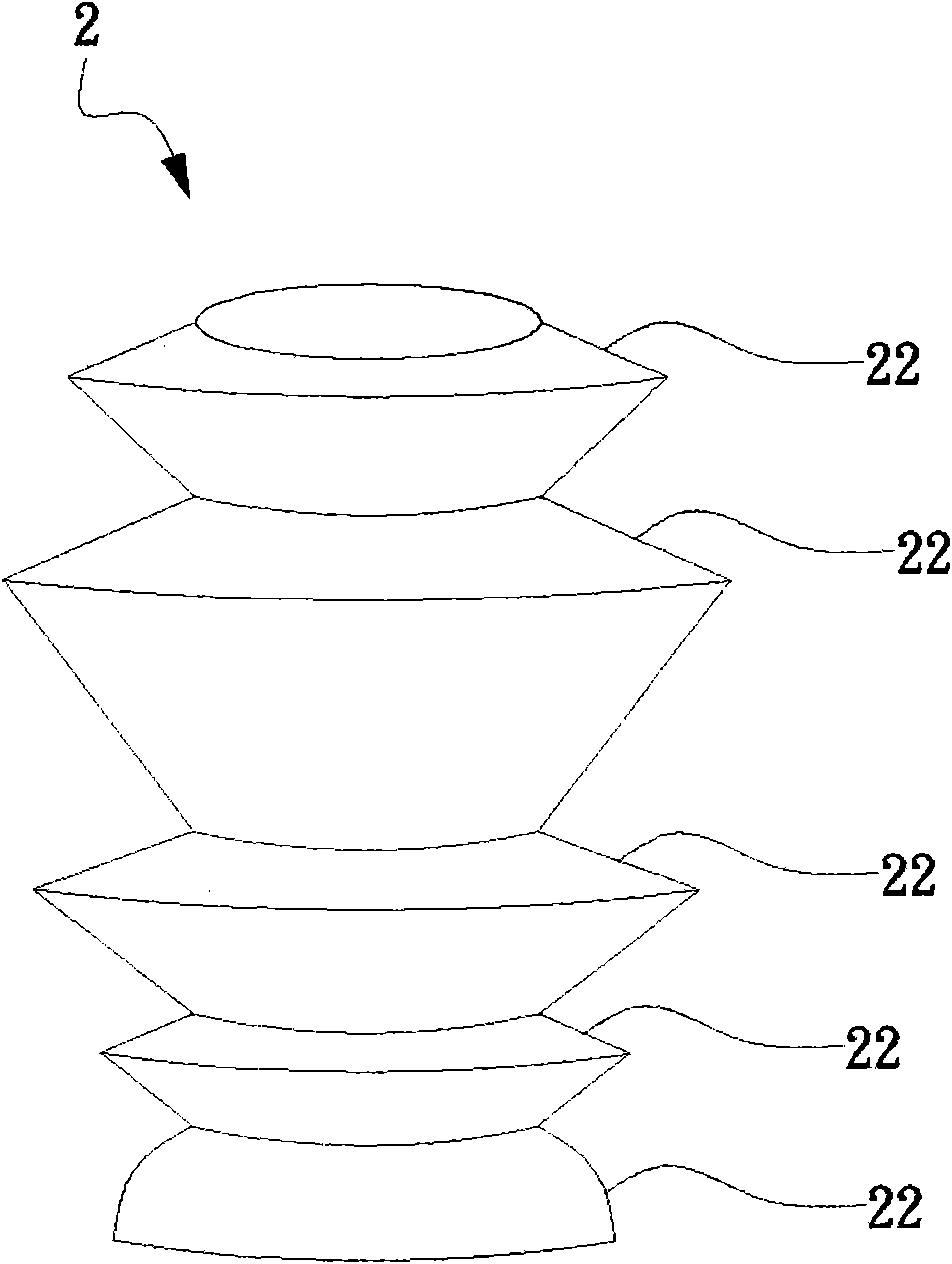

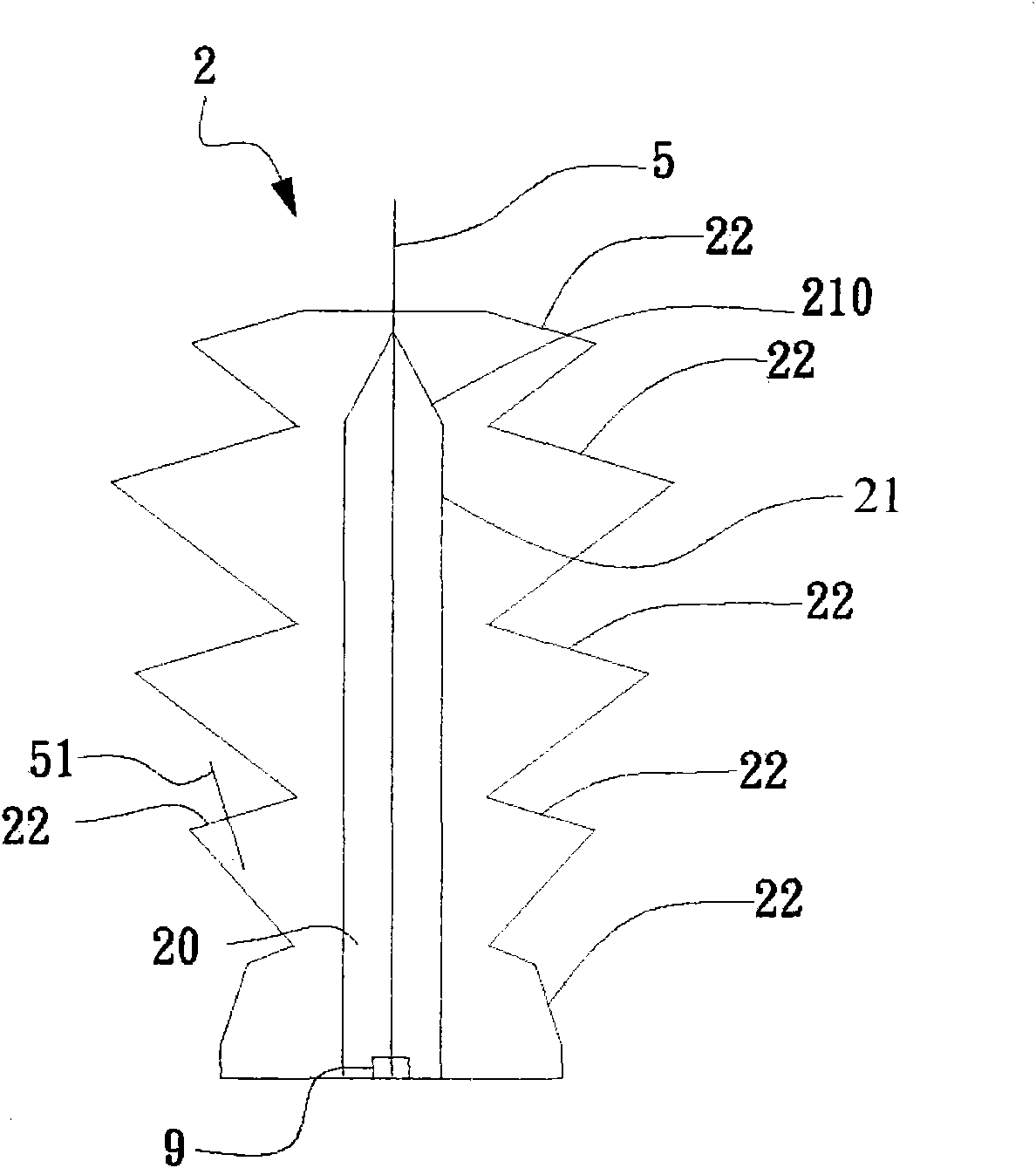

[0086] see Figure 2A as well as Figure 2B As shown, the figure is a perspective view and a schematic cross-sectional view of the first preferred embodiment of the light source packaging structure of the present invention. The light source packaging structure 2 includes: a light source accommodating portion 20 , a first refraction surface 21 and at least one second refraction surface 22 . The light source accommodating portion 20 can accommodate a light source body 9 . The first refraction surface 21 covers the light source body 9 to receive the light generated by the light source body 9 to form a first refraction light. The top of the first refraction surface 21 has a tapered surface 210 . T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com