Touch control panel

A technology of touch panels and substrates, which is applied in the direction of instruments, electrical digital data processing, static electricity, etc., can solve the problems of touch circuit damage, yield reduction, etc., and achieve good electrostatic discharge protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

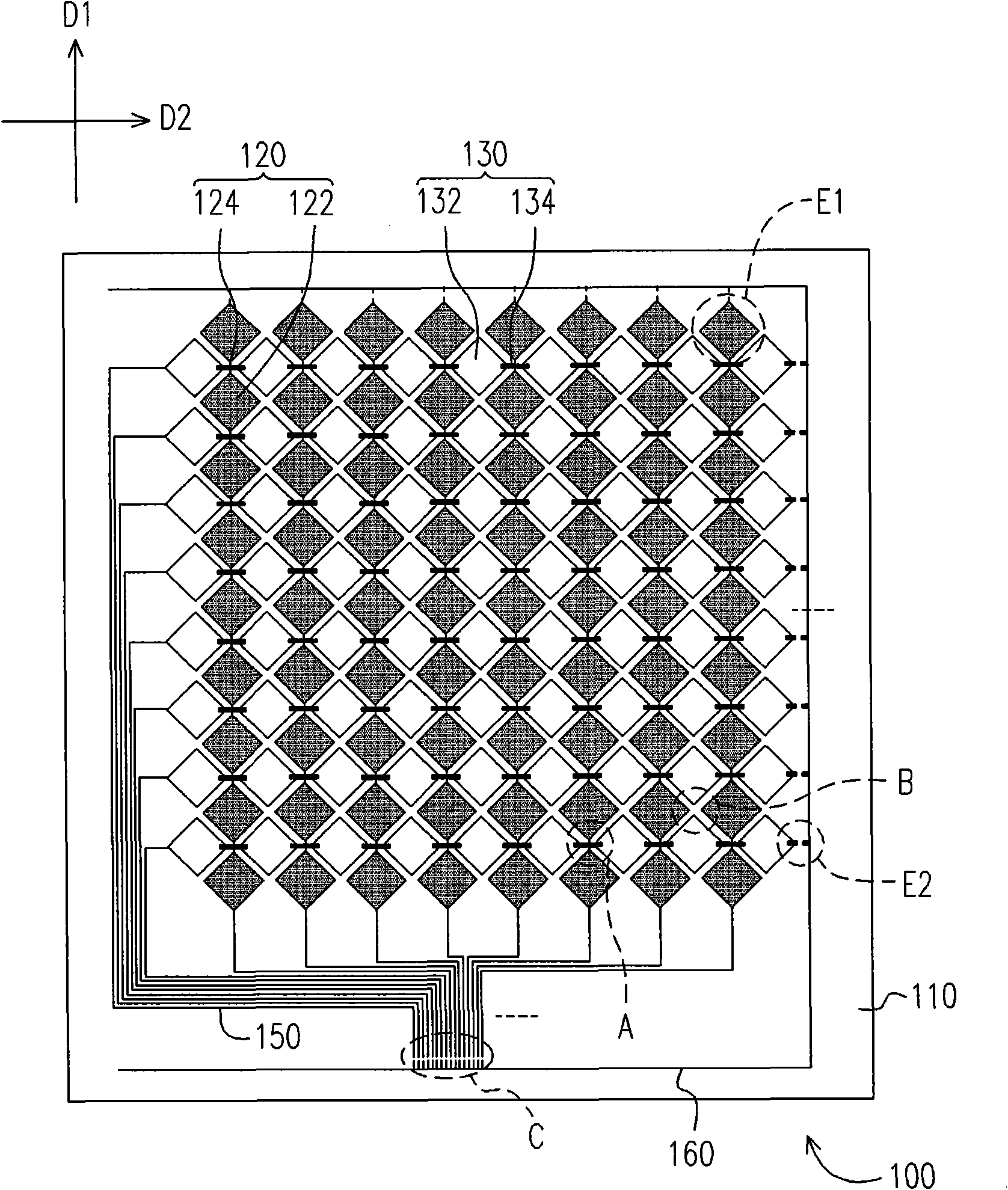

[0070] Image 6 It is a schematic diagram of the touch panel according to the second embodiment of the present invention. Please refer to Image 6 In the touch panel 200 of the present embodiment, the second sensing series 230 arranged in the same row can be divided into two second sensing series 230, where the second sensing series 230 on the left and the distribution The sensing signal transmission line 250 on the left is electrically connected, and the second sensing series 230 on the right is electrically connected with the sensing signal transmission line 250 distributed on the right. In detail, the second sensing series 230 are divided into two groups, and are electrically connected to the two groups of sensing signal transmission lines 250 respectively.

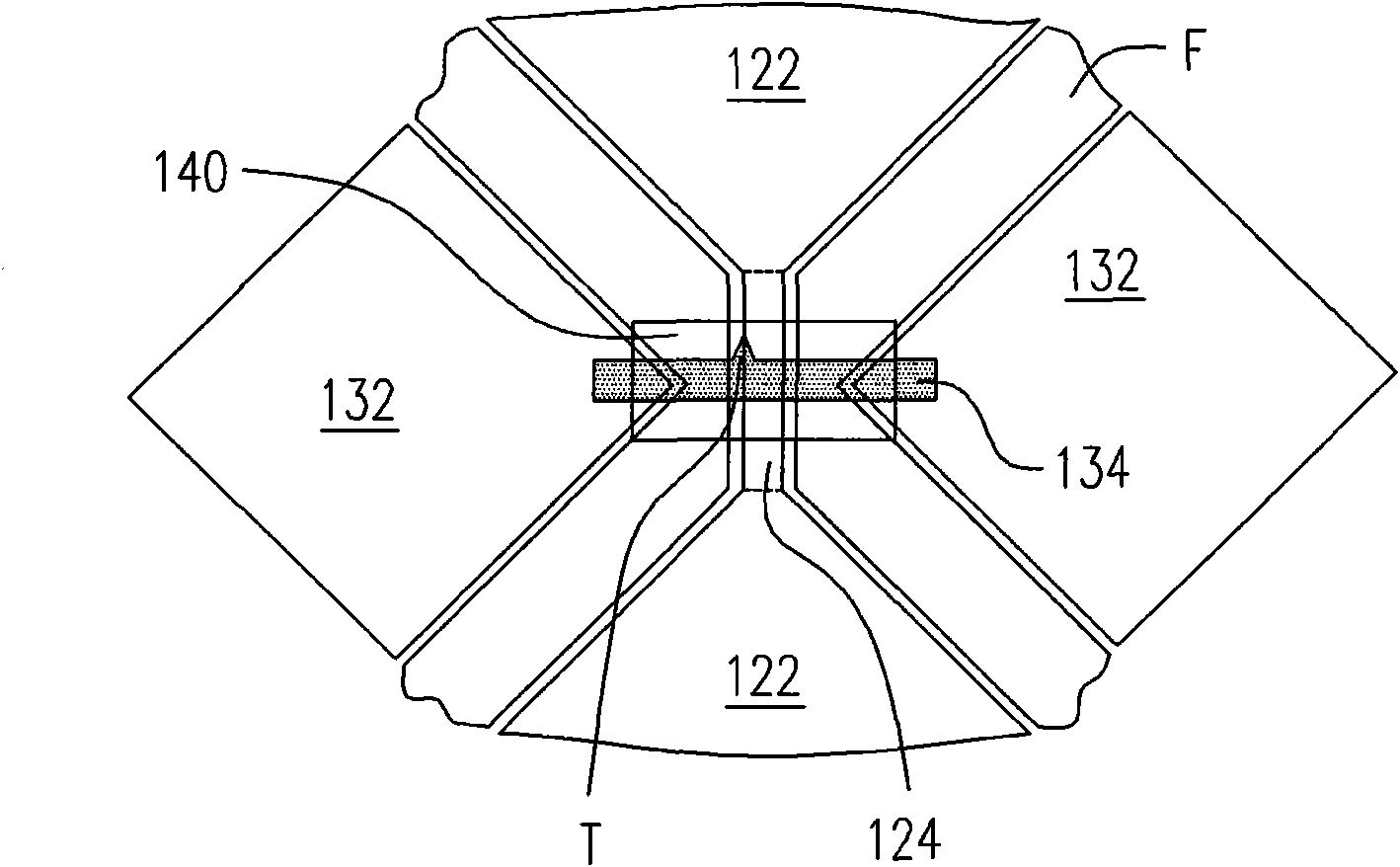

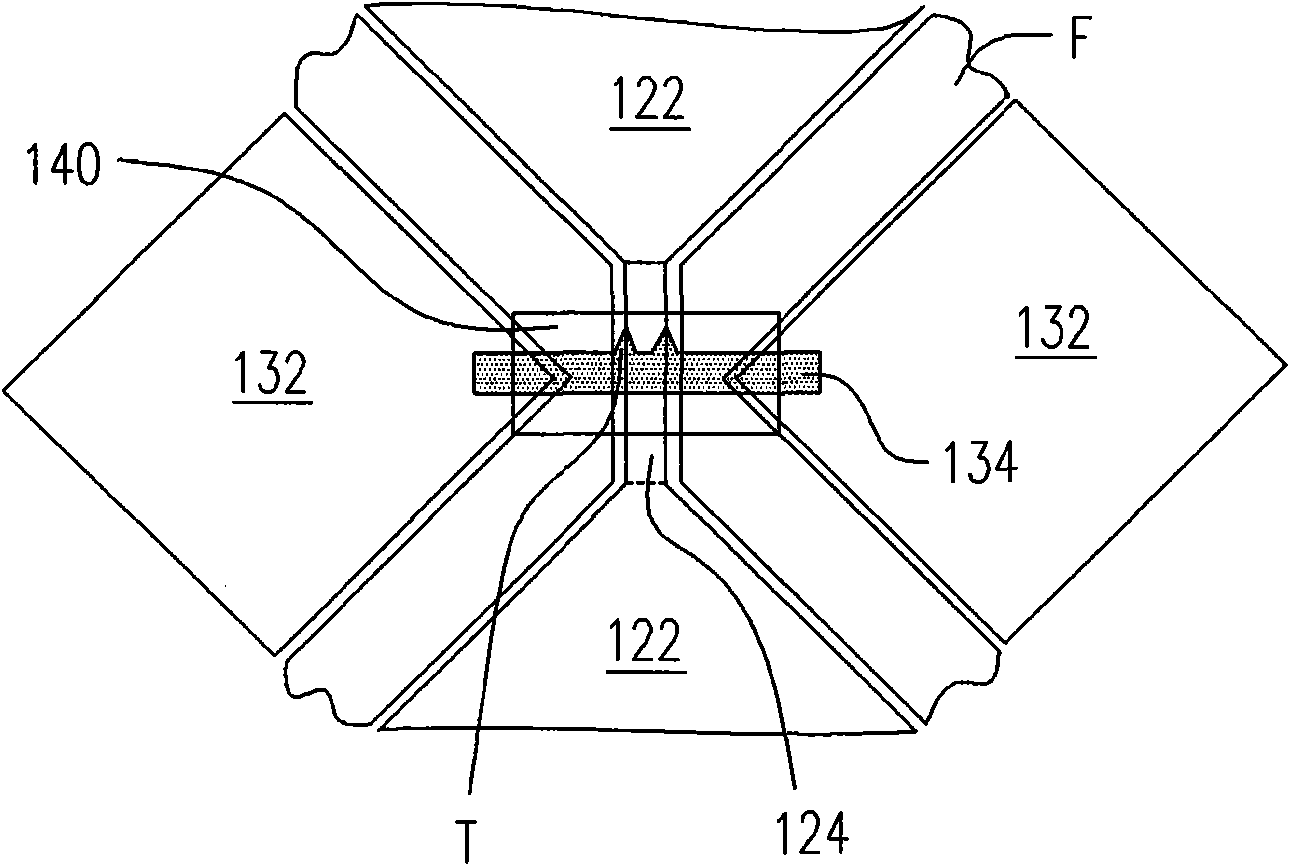

[0071] Figure 7A to Figure 7C for Image 6 A partial enlarged schematic diagram of the middle D area. Please refer to Image 6 versus Figure 7A The touch panel 200 of this embodiment includes a substrate 210, a plurali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com