Backlight module of liquid crystal display panel

A technology for backlight modules and liquid crystal panels, which is applied to electric light sources, components of lighting devices, safety devices of lighting devices, etc., can solve the problems of cumbersome assembly process, warping of aluminum foil, abnormal short circuit, etc., and achieves good conduction effect. Firm connection, good electrostatic discharge protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

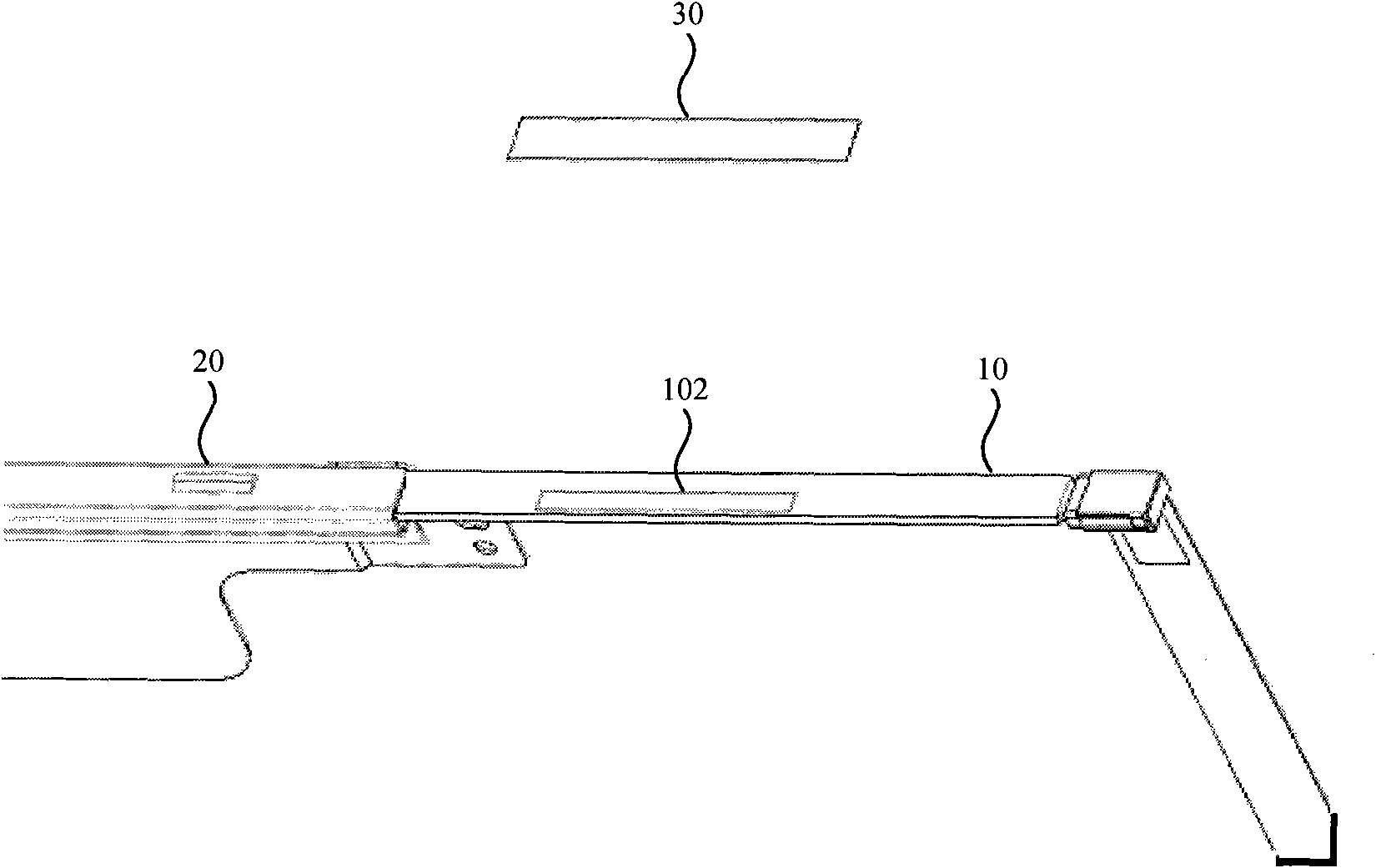

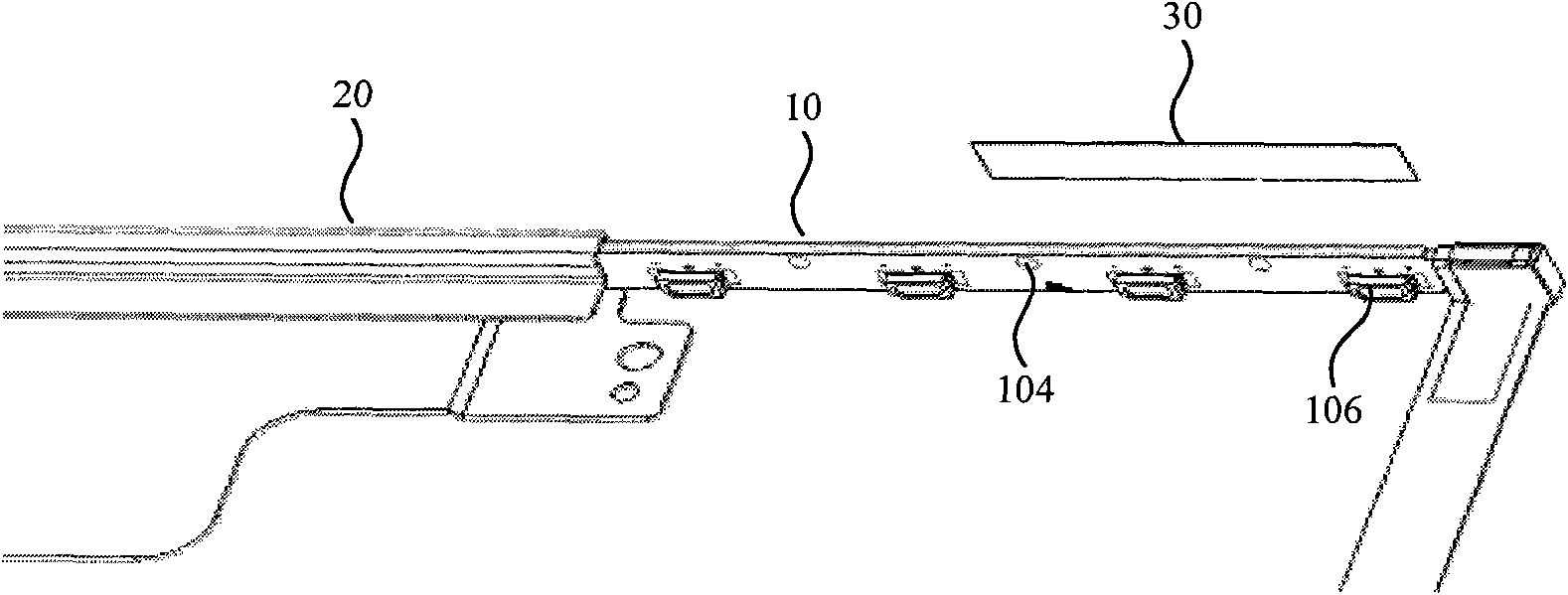

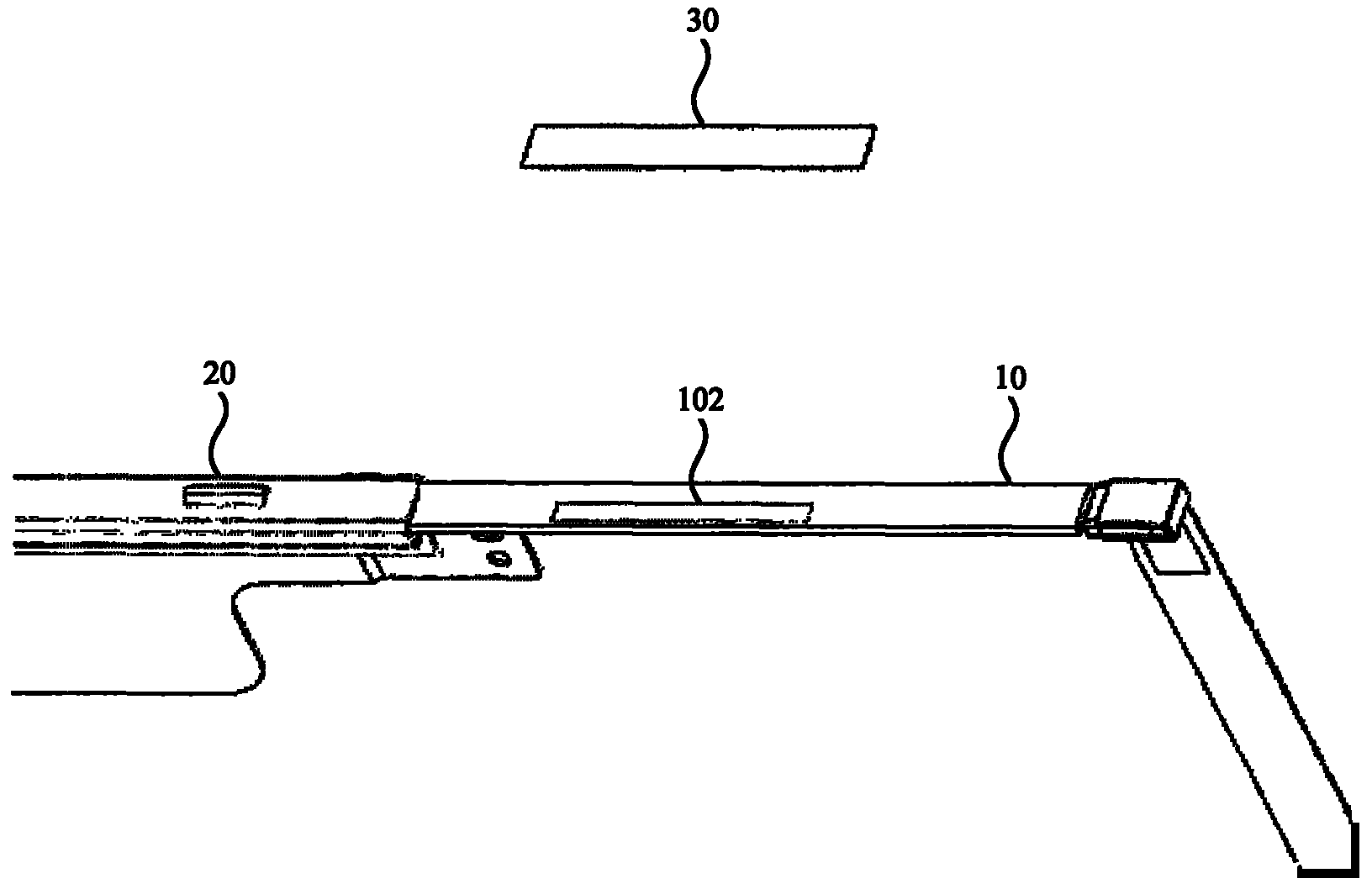

[0020] figure 1 According to a preferred embodiment of the present invention, a schematic diagram of a surface of a light bar used for electrostatic discharge protection in a backlight module of a liquid crystal panel is shown. As mentioned above, in order to prevent high-voltage static electricity generated during manual or machine operation, it is often necessary to set up a certain static electricity discharge path to protect the backlight LED of the backlight module and the corresponding circuit board from damage. refer to figure 1 , the backlight module at least includes: a light bar 10 , a bracket 20 and a connecting piece 30 . Wherein, the bracket 20 is used for accommodating the light bar 10 when the light bar 10 is pushed in. Moreover, the light bar 10 has two surfaces, namely a first surface and a second surface, and the second surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com