Hexagon-channel silicon light conduction pipe

A hexagonal and channel technology, applied in the field of silicon light guides, can solve the problems of unreachable light transmission and achieve ideal transmission effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

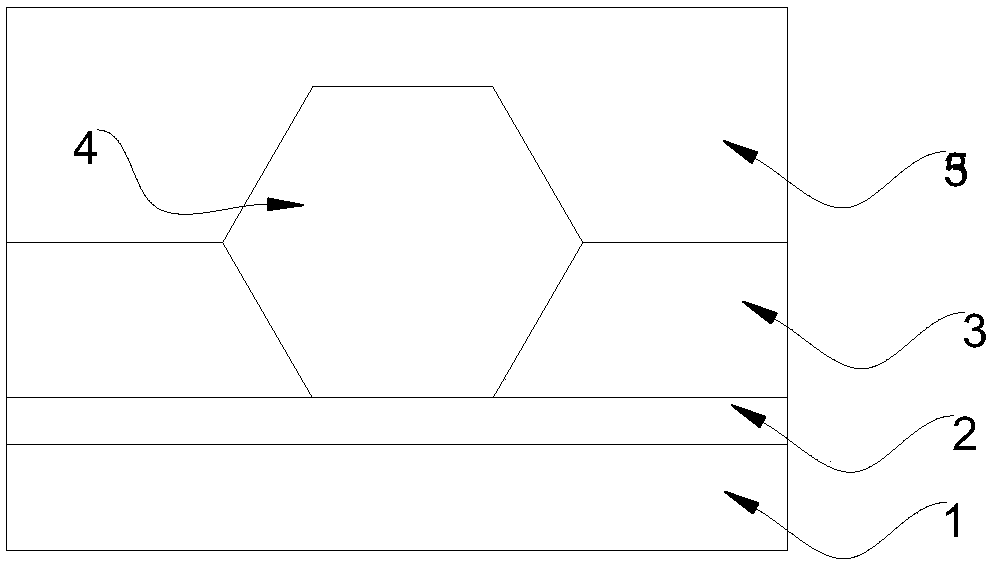

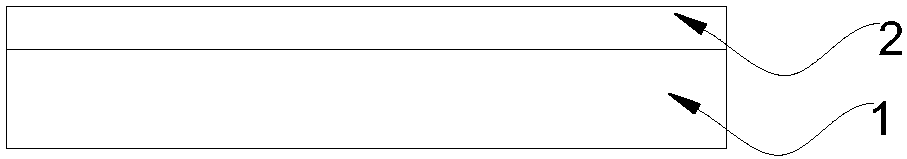

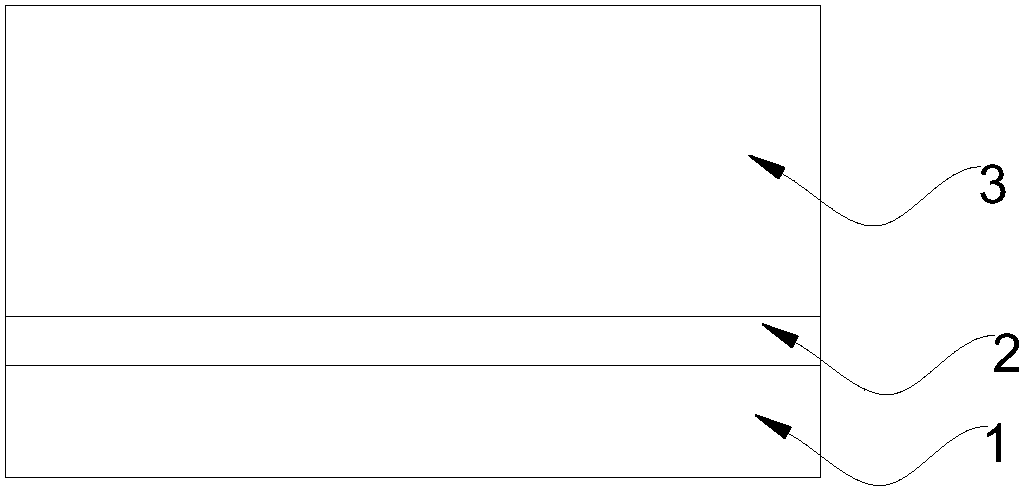

[0019] figure 1 It is a structural representation of the present invention. Such as figure 1 As shown, the present invention includes a silicon-based substrate 1 . A first silicon oxide layer 2 is epitaxially formed on the silicon base substrate 1 . A silicon region 4 with a regular hexagonal cross-section grows on the first silicon oxide layer 2 . The bottom edge of the silicon region 4 coincides with the surface of the first silicon oxide layer 2 . Bounded by the central axis in the horizontal direction of the regular hexagonal cross-section of the silicon region 4, a second silicon oxide layer 3 is wrapped around the silicon region 4 between the central axis and the first silicon oxide layer 2, On the second silicon oxide layer 3 , a third silicon oxide layer 5 is wrapped around the silicon region 4 . The length of the diagonal of the cross section of the silicon region 4 is 1 μm to 3 μm. In this embodiment, the silicon oxide layer mentioned above refers to the dioxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com