Method for operating a cleaning apparatus of a printing press

A technology for cleaning devices and printing machines, applied to printing machines, general parts of printing machinery, printing, etc., can solve the problems of not being able to clean thoroughly, not being able to make practical and beneficial contributions, and achieve the effect of strengthening contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

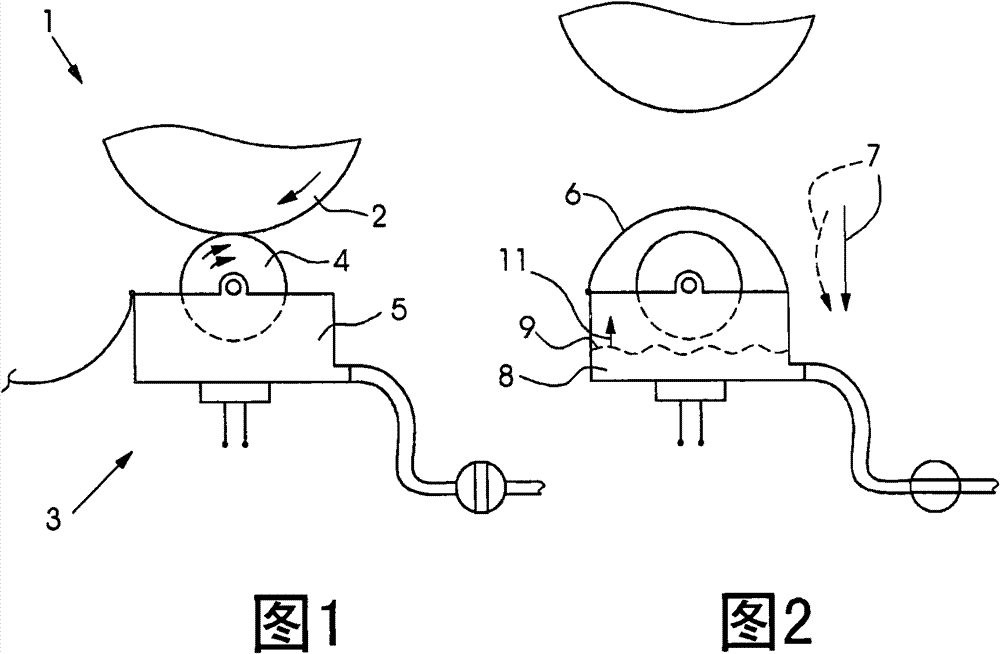

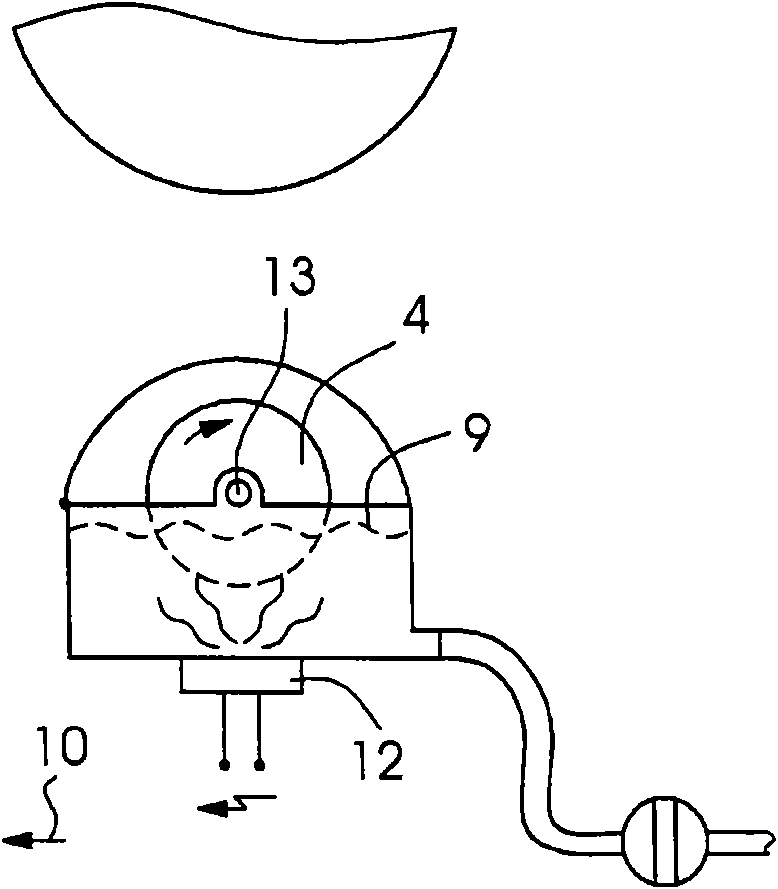

[0027] figure 1 A partial view of a printing press 1 is shown in . The printing press 1 is an offset lithographic printing press for printing sheets. The detail shows the components of the varnishing device of the printing press 1 . The varnishing device comprises a cylinder 2 which carries a blanket for full-surface varnishing or a flexographic printing plate for partial varnishing. A cleaning device 3 is assigned to the drum 2 . During the cleaning of the cylinder 2 , the brush roller 4 of the cleaning device 3 rests against this cylinder, or more precisely against the blanket or flexographic printing plate. The brush roller 4 is partially immersed in the tank 5 , with which the brush roller 4 forms a structural unit that is movable towards and away from the drum 2 .

[0028] figure 2 It is shown that the cover 6 of the tub 5 is closed in order to cover the opening of the tub 5 directed toward the drum 2 and the part of the brush roller 4 protruding from the tub 5 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com