Winding connection structure for double-active-part on-load-tap-changing auto-transformer

A voltage regulating transformer and wiring structure technology, applied in the direction of transformer/inductor coil/winding/connection, transformer, variable transformer, etc., can solve the problem of large voltage deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

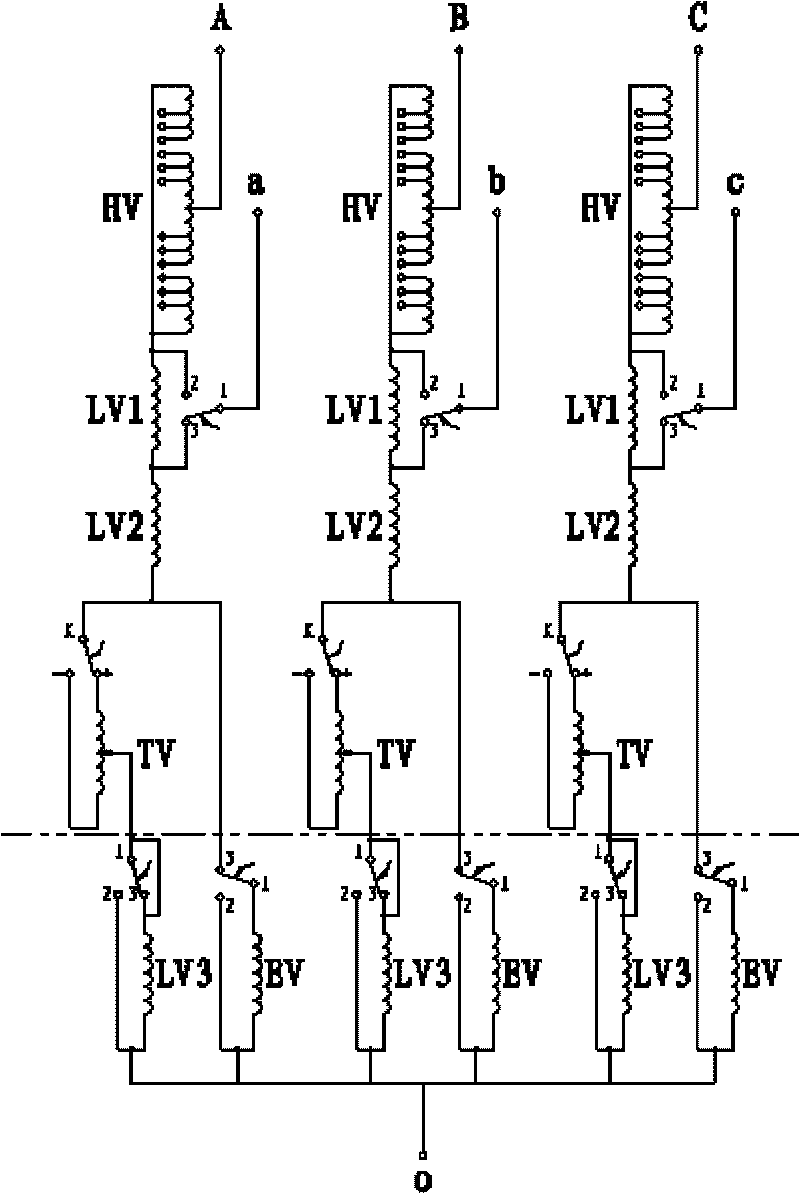

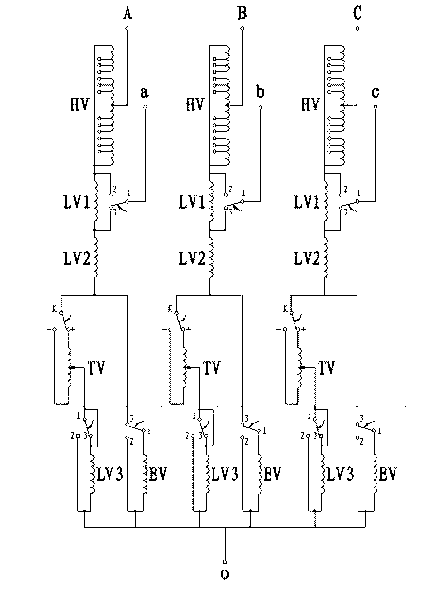

[0012] Below in conjunction with the accompanying drawings, the present invention will be further described through embodiments.

[0013] In the embodiment, the winding wiring structure of a double-body self-coupling on-load tap changer includes a series winding HV, a common winding LV2, and a switch winding LV1. There is a switching winding LV1 between it and the common winding LV2, and it is controlled by an off-load switch to be serially connected to the series winding or to the common winding, that is, through this control, the number of turns of the common winding can be greatly changed to achieve low voltage in two The voltage level of the grid varies greatly.

[0014] In order to make the low-voltage windings under the two voltage levels share a set of voltage regulating windings and on-load switches, and to ensure that the voltage error of each tap is as small as possible, a new dual-body, variable flux compensation voltage regulation structure is adopted: There are t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap