Thrust ball rotor supported micro-cylinder ultrasonic motor

An ultrasonic motor, rotor support technology, applied in the direction of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc. Design and processing problems, to achieve the effect of short structure, simple structure and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

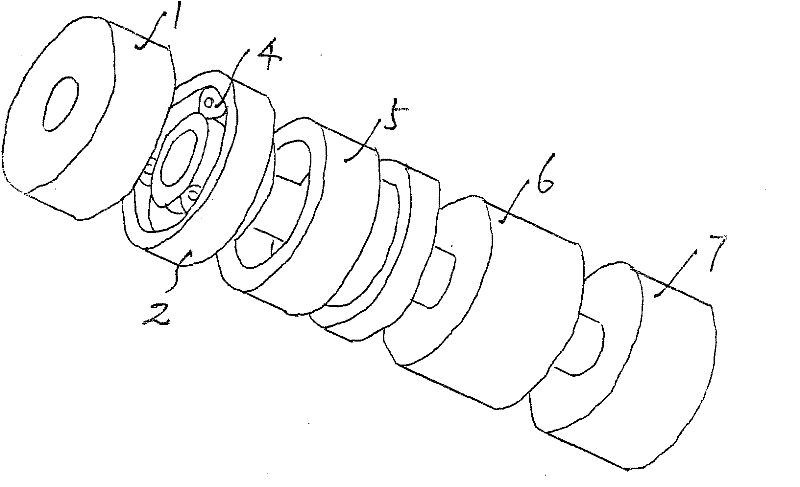

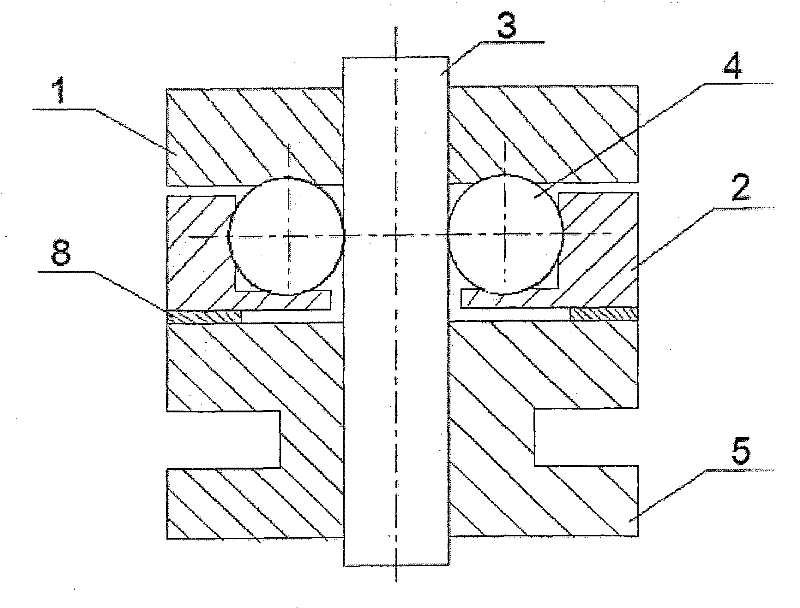

[0020] The thrust ball rotor supported miniature cylindrical ultrasonic motor of the present invention is composed of a rotor 2, a steel ball 4, a stator upper matching block 5, a stator lower matching block 7, piezoelectric ceramics 6, connectors 8, fixing nuts and gaskets. The upper matching block of the stator and the lower matching block of the stator can be connected through a threaded matching mechanism, or can be threaded with the shaft (shaft sleeve). They clamp piezoelectric ceramics and lock them into a stator. The upper matching block of the stator is slotted to amplify the stator vibration. Stator diameter 4mm.

[0021] Such as figure 2 shown. The stator and the end cover 1 are fixedly connected with the shaft 3 directly. The rotor is processed into a ring shape, leaving a certain bottom surface to support the steel ball, the rotor and the shaft are separated, and the steel ball is used as the axial and radial support workpiece of the rotor at the same time. Th...

Embodiment 2

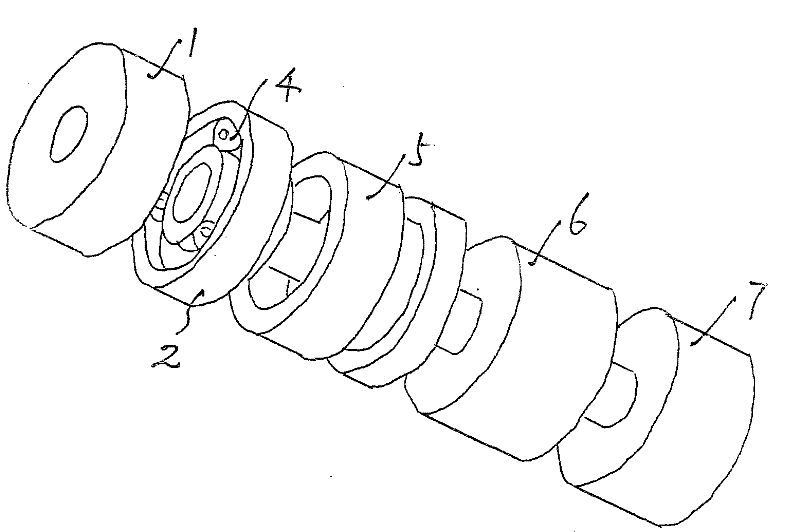

[0024] The thrust ball rotor supported miniature cylindrical ultrasonic motor of the present invention is composed of a rotor, a steel ball, an upper matching block on a stator, a lower matching block on a stator, piezoelectric ceramics, a bearing, a fixing nut and a washer. The upper matching block of the stator and the lower matching block of the stator can be connected through a threaded matching mechanism, or can be threaded with the shaft (shaft sleeve). They clamp piezoelectric ceramics and lock them into a stator. The upper matching block of the stator is slotted to amplify the vibration of the stator.

[0025] The surface of the rotor and the bottom surface of the end cover are processed with arc-shaped grooves for ball rolling, and the steel balls in the groove can bear large axial loads. Both the end cover and the stator are fixedly connected to the shaft, and the rotor is connected to the shaft through a bearing. The preload is applied through the nut gasket above t...

Embodiment 3

[0028] The thrust ball rotor supported miniature cylindrical ultrasonic motor of the present invention is composed of a rotor, a steel ball, an upper matching block on a stator, a lower matching block on a stator, piezoelectric ceramics, a bearing, a fixing nut and a washer. The upper matching block of the stator and the lower matching block of the stator are screw fit mechanisms. They clamp piezoelectric ceramics and lock them into the stator. The upper matching block of the stator is slotted to amplify the vibration of the stator.

[0029] The surface of the rotor and the bottom surface of the end cover are processed with arc-shaped grooves for ball rolling, and the steel balls in the grooves can bear certain axial loads. The rotor is fixedly connected to the shaft, and the end cover and stator are connected to the shaft through bearings. The pre-pressure is applied on the end cover through the nut gasket, and the pressure is evenly distributed on each steel ball, so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com