Traveling wave type ultrasonic motor of minitype column

An ultrasonic motor, traveling wave type technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc. complex problems, to achieve the effect of simple structure, solving the problem of two-phase mode merger, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

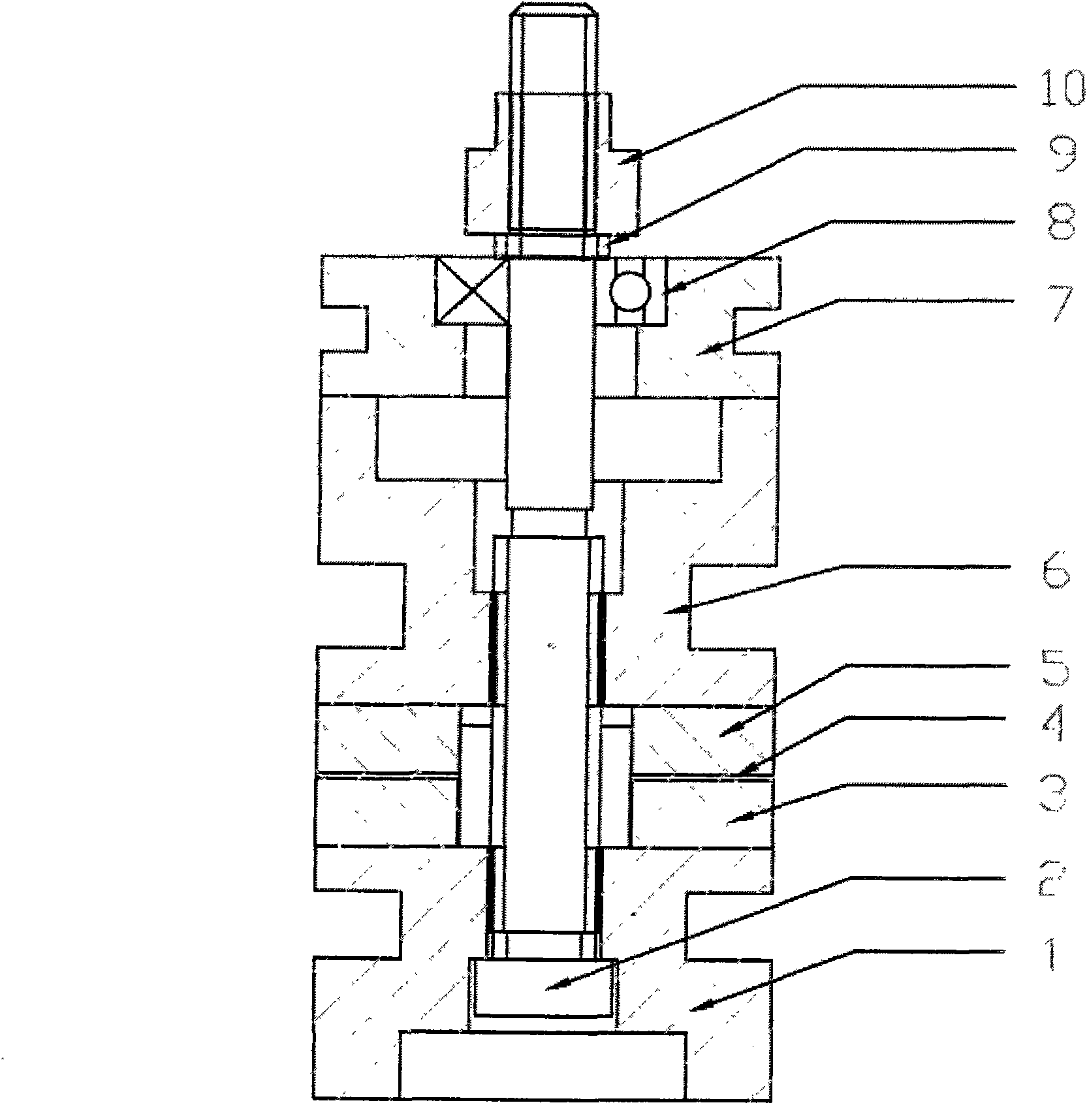

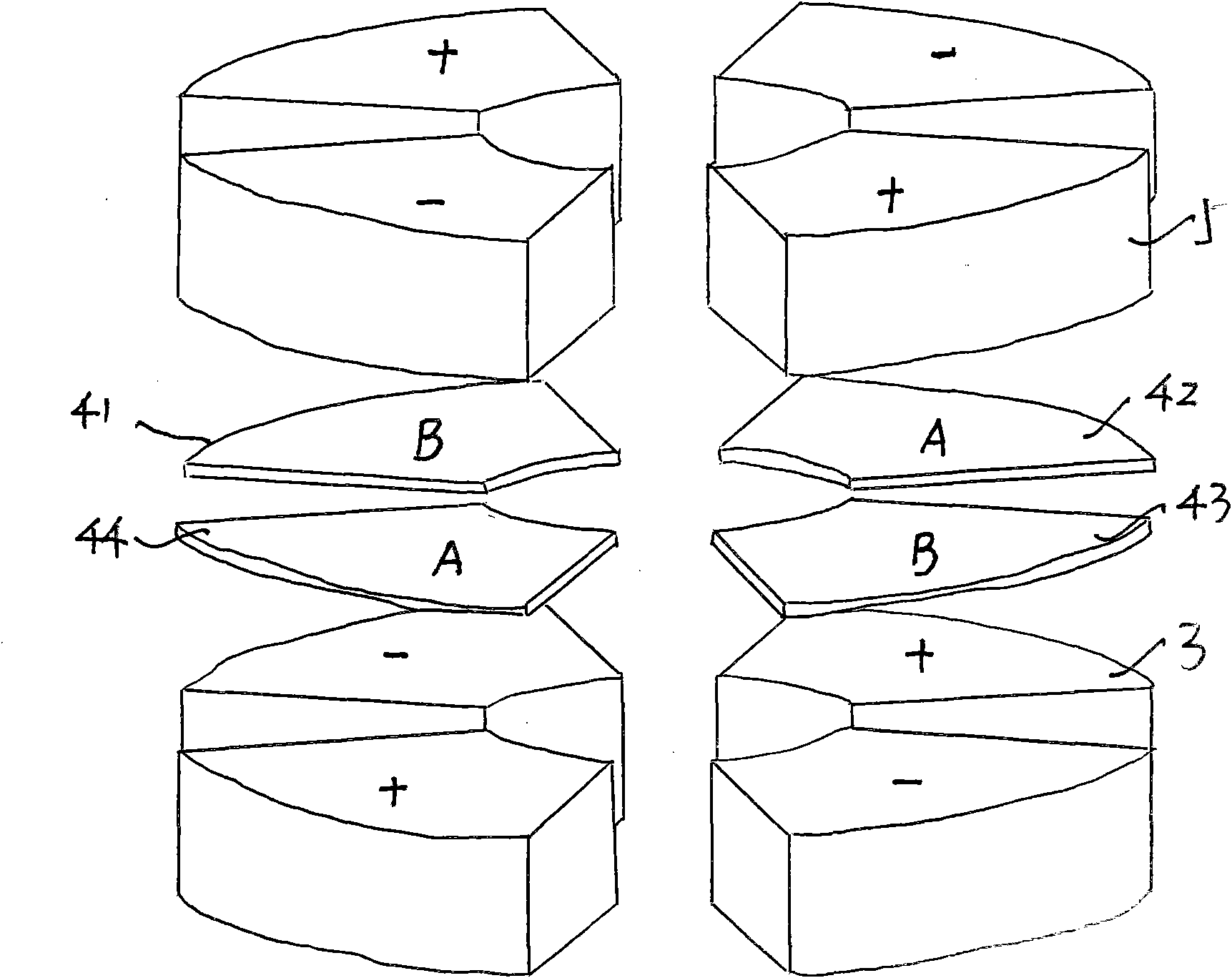

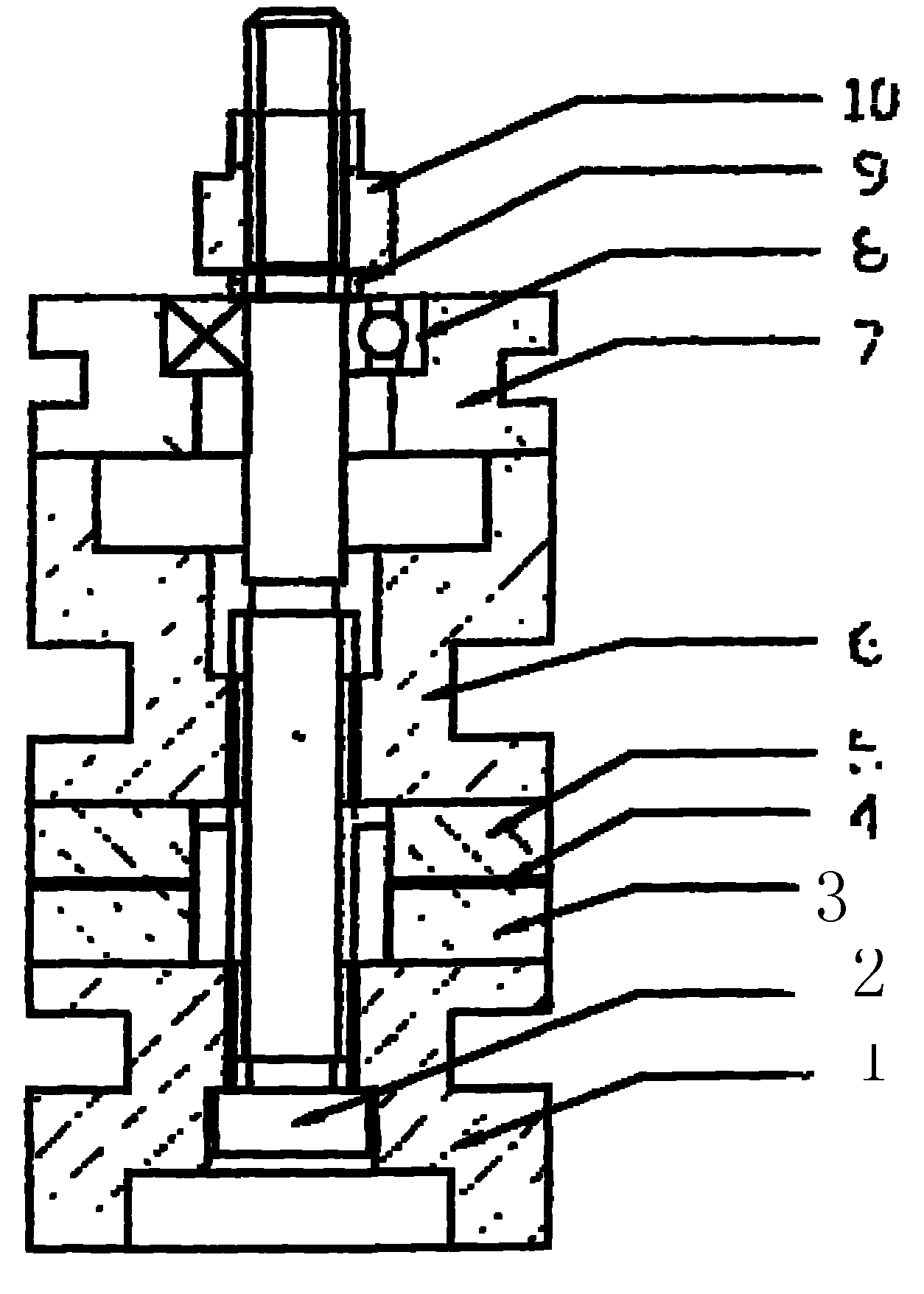

[0015] A small cylindrical traveling wave ultrasonic motor, including a stator, the stator has an upper stator matching block 6 and a lower stator matching block 1 connected to the shaft 2, and upper and lower piezoelectric ceramic sheets are clamped between the upper and lower matching blocks of the stator 5.3. The upper and lower piezoelectric ceramic sheets are divided into four partitions, each partition is insulated from each other and polarized along the thickness direction of the ceramic, and the adjacent partitions are polarized in opposite directions. The upper and lower piezoelectric ceramic sheets Stacked together in opposite polarity, 4 electrodes 4 are evenly distributed between the upper and lower piezoelectric ceramic sheets (i.e. the first electrode sheet 41, the second electrode sheet 42, the third electrode sheet 43 and the fourth electrode sheet 44) , that is, four polarization areas, the excitation voltage is applied to the piezoelectric ceramics through the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com