Linear type magnetic fluid traveling wave pump

A magnetic fluid, linear technology, applied in the direction of wave-generating pumps, pumps, non-variable pumps, etc., can solve the problems that the magnetic field effect of traveling waves has not been studied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

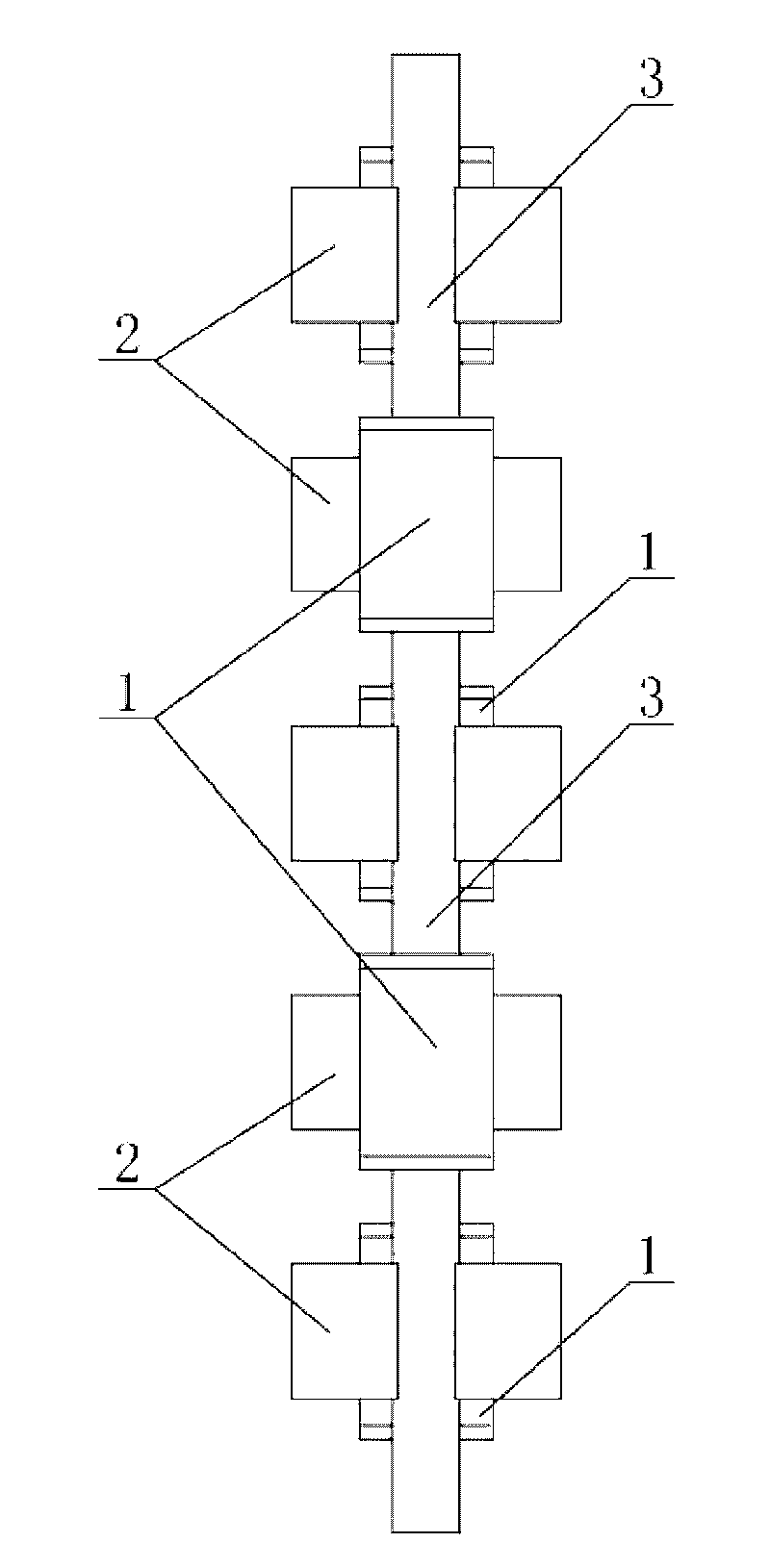

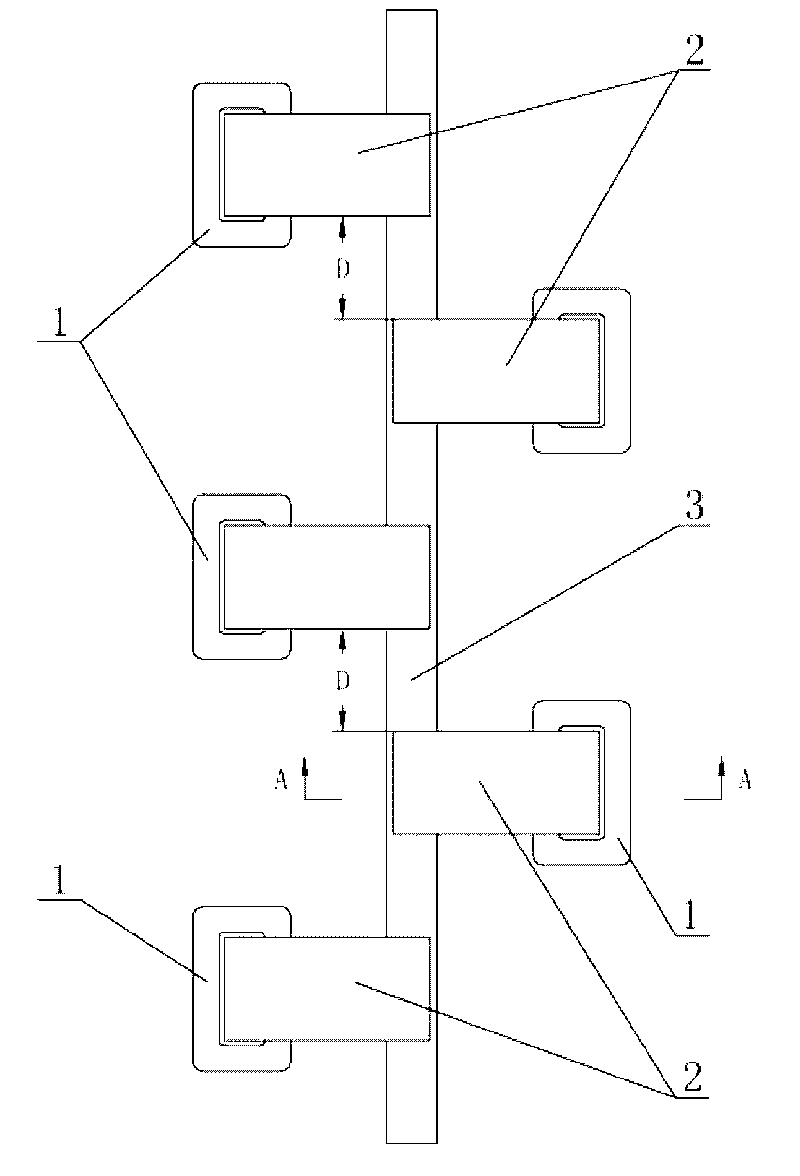

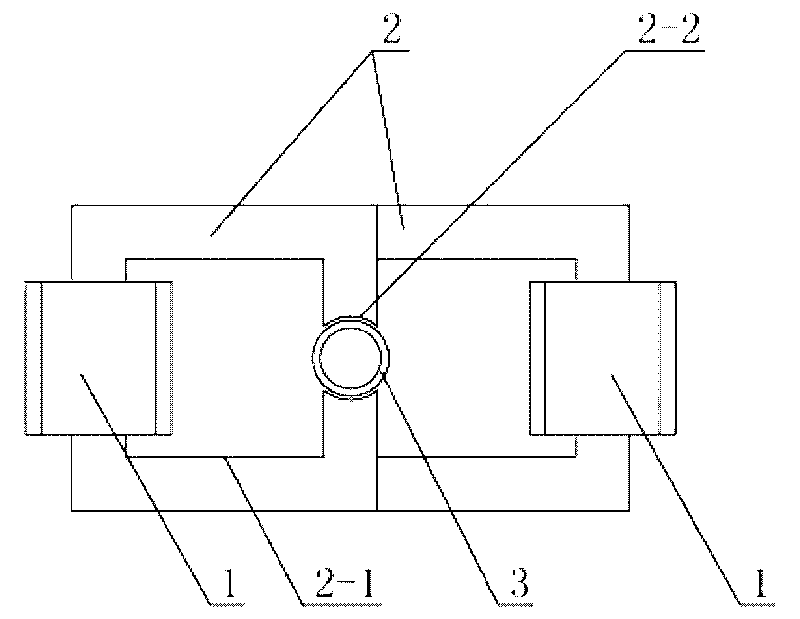

[0007] Specific implementation mode one: as Figure 1~4 As shown, the linear magnetic fluid traveling wave pump described in this embodiment is composed of three to ten energized coils 1, three to ten magnetic steel bodies 2 and conduits 3, and the middle part of the magnetic steel body 2 is along the There is a through hole 2-1 in the thickness direction, and a gap 2-2 connected with the through hole 2-1 is provided on the side wall of the magnetic steel body 2 along the thickness direction of the magnetic steel body 2. The number of energized coils 1 and the magnetic The number of steel bodies 2 is uniformly set, and a energized coil 1 is wound on the other side wall corresponding to the notch 2-2 on each magnetic steel body 2, and the conduit 3 passes through three to ten magnetic steel bodies in sequence 2, and two adjacent magnetic steel bodies 2 are arranged alternately on both sides of the conduit 3, and the distance D between two adjacent magnetic steel bodies 2 along ...

specific Embodiment approach 2

[0009] Specific implementation mode two: as Figure 1~4 As shown, the non-magnetic material in this embodiment is glass. With such a design, the glass can act as a magnetic barrier. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: as Figure 1~4 As shown, the non-magnetic permeable material in this embodiment is plastic. With such a design, the plastic can play the role of magnetic isolation. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com