Linear magnetic fluid traveling wave pump with belt wheels

A magnetic fluid and pulley technology, applied in the direction of electrical components, electromechanical devices, etc., can solve the problems of high cost and complex structure, and achieve the effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

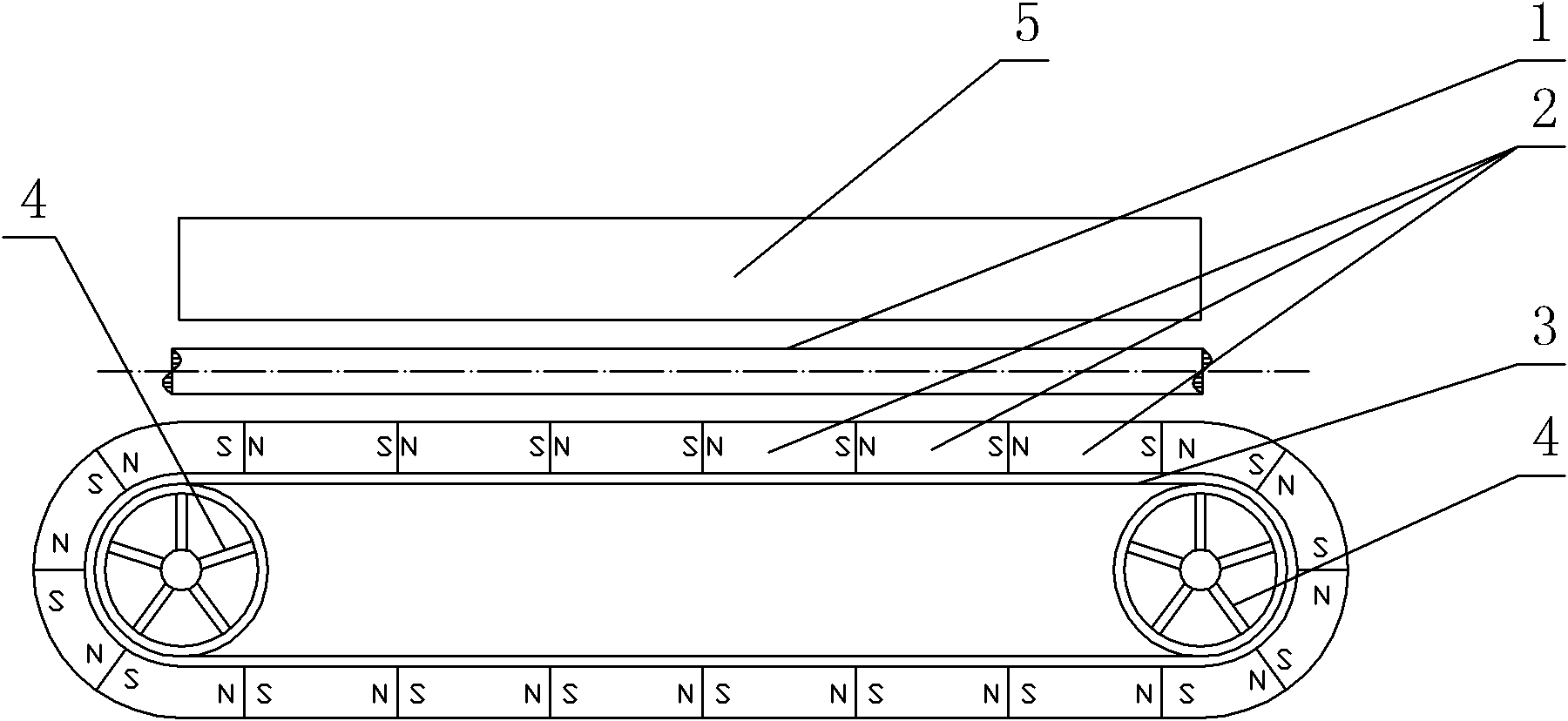

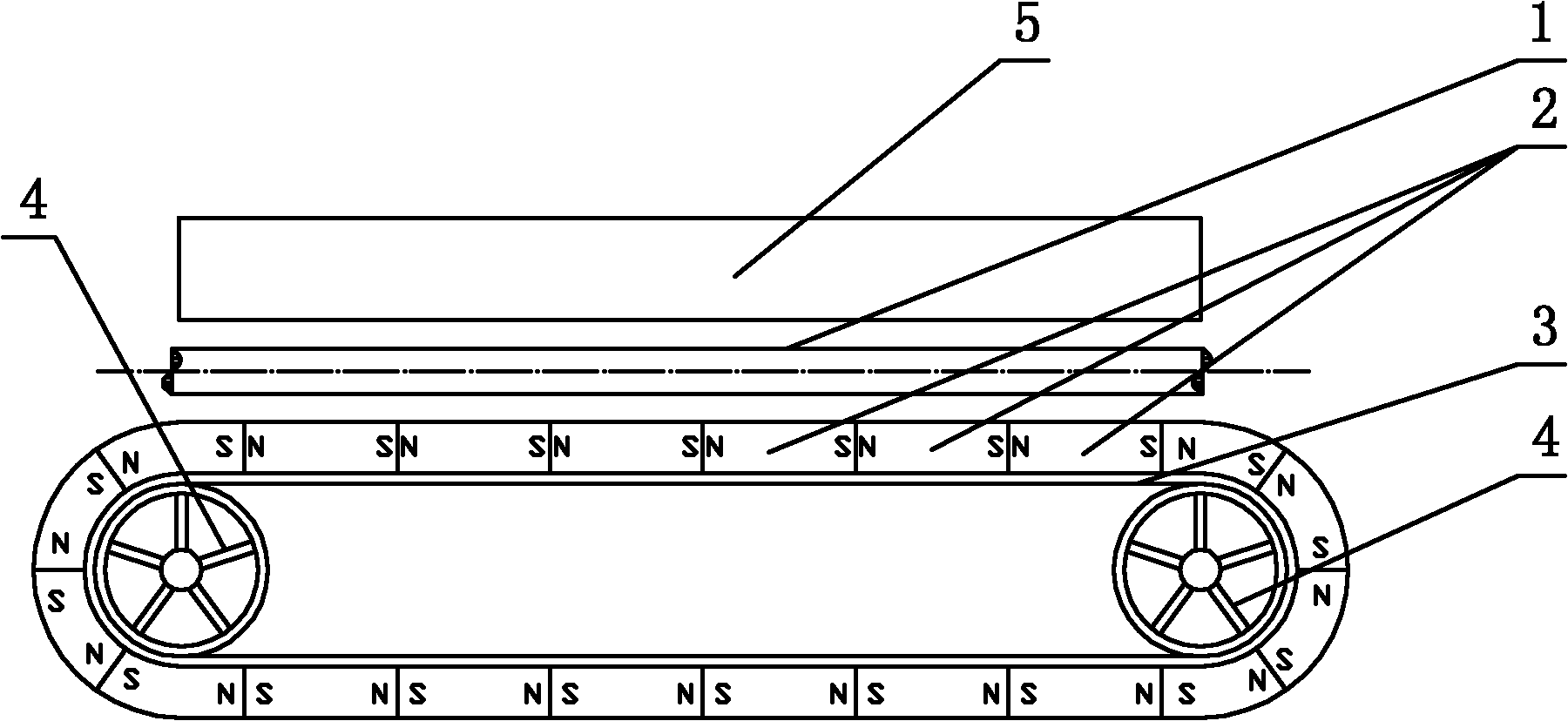

[0007] Specific implementation mode one: as figure 1 As shown, the linear magnetic fluid traveling wave pump with pulleys in this embodiment includes a conduit 1 and a plurality of permanent magnet monomers 2, and the traveling wave pump also includes an endless flat belt 3 and two pulleys 4, The annular flat belt 3 is installed on two pulleys 4, and a plurality of permanent magnet monomers 2 are connected end to end along the outer ring surface of the annular flat belt 3, and the magnetization direction of two adjacent permanent magnet monomers 2 is the same, The conduit 1 is arranged in parallel along the length direction of the endless flat belt 3, and is adjacent to the permanent magnet monomer 2 on one side of the endless flat belt 3. The conduit 1 is made of a non-magnetic material, and the conduit 1 is filled with magnetic fluid. .

[0008] Magnetic fluid is a new type of functional material. It is a stable colloidal liquid formed by uniformly dispersing magnetic solid...

specific Embodiment approach 2

[0009] Embodiment 2: The non-magnetic material in this embodiment is glass. With such a design, the glass can act as a magnetic barrier. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0010] Embodiment 3: The non-magnetically permeable material described in this embodiment is plastic. With such a design, the plastic can play the role of magnetic isolation. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com