Horizontal screw lead supporting device

A technology of a support device and a horizontal screw, applied in the field of machine tools, can solve the problem of not considering the rotation of the screw, and achieve the effect of a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

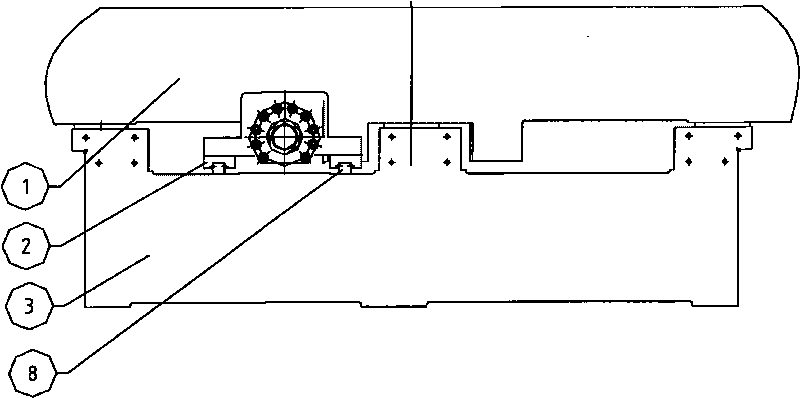

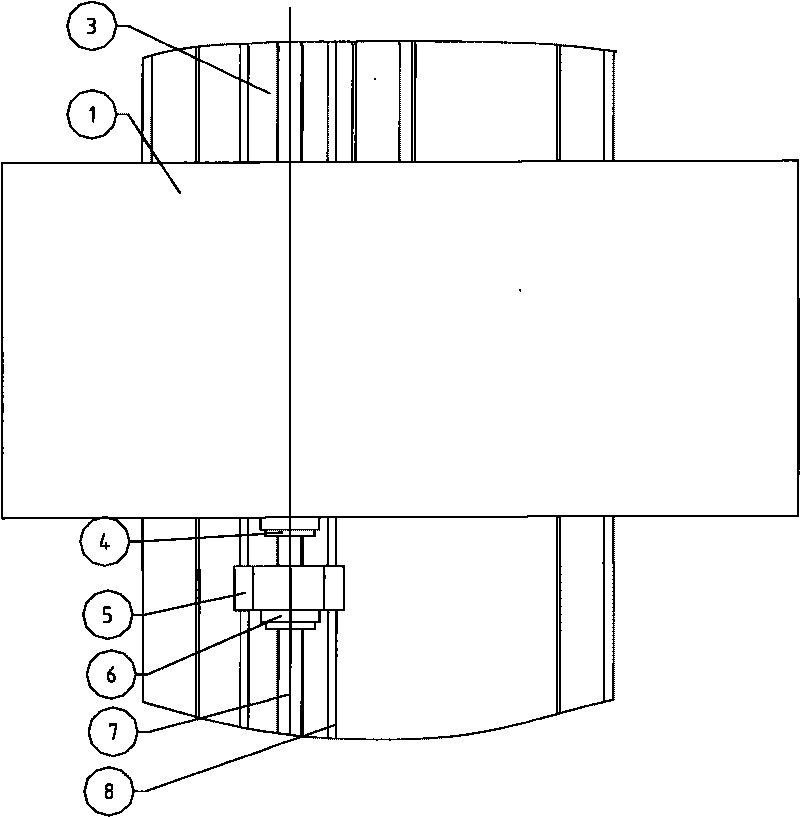

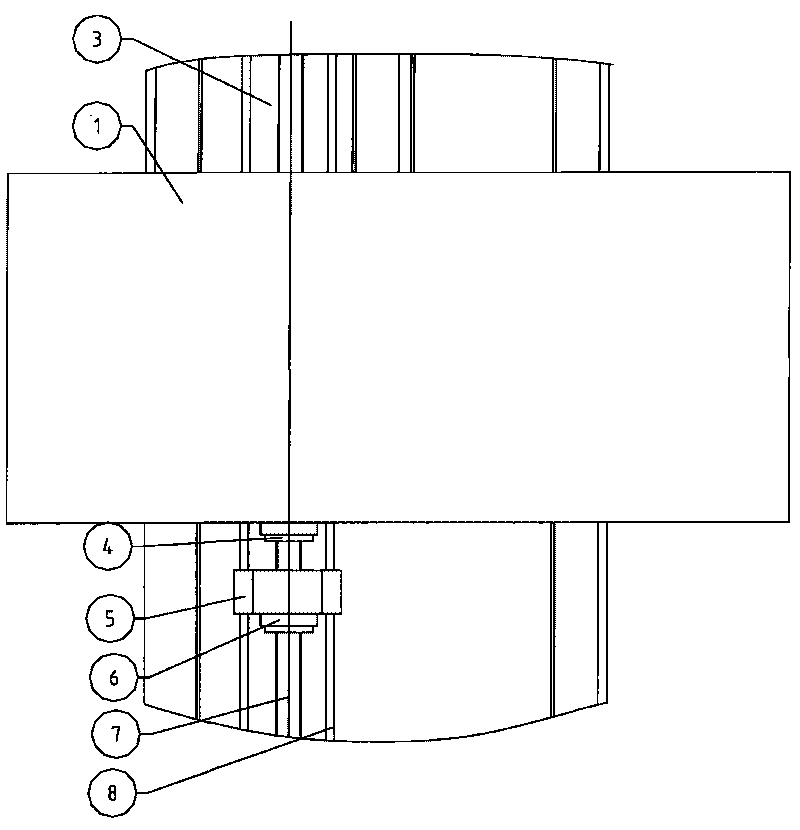

[0010] exist figure 1 , figure 2 Among them, the present invention is provided with bed 3 and moving part 1, and screw 7 is fixed on bed 3, and the two sides of screw 7 are respectively fixed with the line track 8 that is parallel with lead screw 7, and slides on two line rails 8 Block 2 is equipped with a supporting plate 5, the supporting plate 5 is fixed on the rear screw nut 6, the moving part 1 is fixed on the front screw nut 4, and the rear screw nut 6 and the front screw nut 4 move synchronously on the screw 7 .

[0011] The line rail 8 of the present invention is fixed on the bed 3, so that the supporting plate 5 can move freely on the line rail 8, the supporting plate 5 has good guiding precision, and the rear screw nut 6 in the supporting plate 5 moves on the leading screw 7. When the lead screw 7 sags and vibrates, the supporting plate 5 can effectively support the deformed area and prevent shaking when passing through the deformed area, because the rear lead scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com