Reentry method of later-operation pipe column of multi-branch well

An operation string, multi-branch technology, applied in directional drilling, earthmoving, wellbore/well components, etc., can solve the problems of perforating gun detonation, inability to hold pressure, poor adaptability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The method discloses a method for reentrying a post-operation pipe string in a multi-branch well, and the steps are as follows:

[0027] (1) During or after drilling and completion, a main branch 2 is provided at the bottom of the main wellbore 1, and at least two side branches are sidetracked by opening a window in the main wellbore 1, and a delivery pipe is used in the main wellbore 1 At least two guide sleeves are lowered into the column. The size of each guide sleeve is the same. The two guide sleeves are respectively anchored above the window of the side branch. There is a guide groove in each guide sleeve. The included angle between the groove and the projection of the side branch on the horizontal plane is defined as the borehole guiding angle, which is preset;

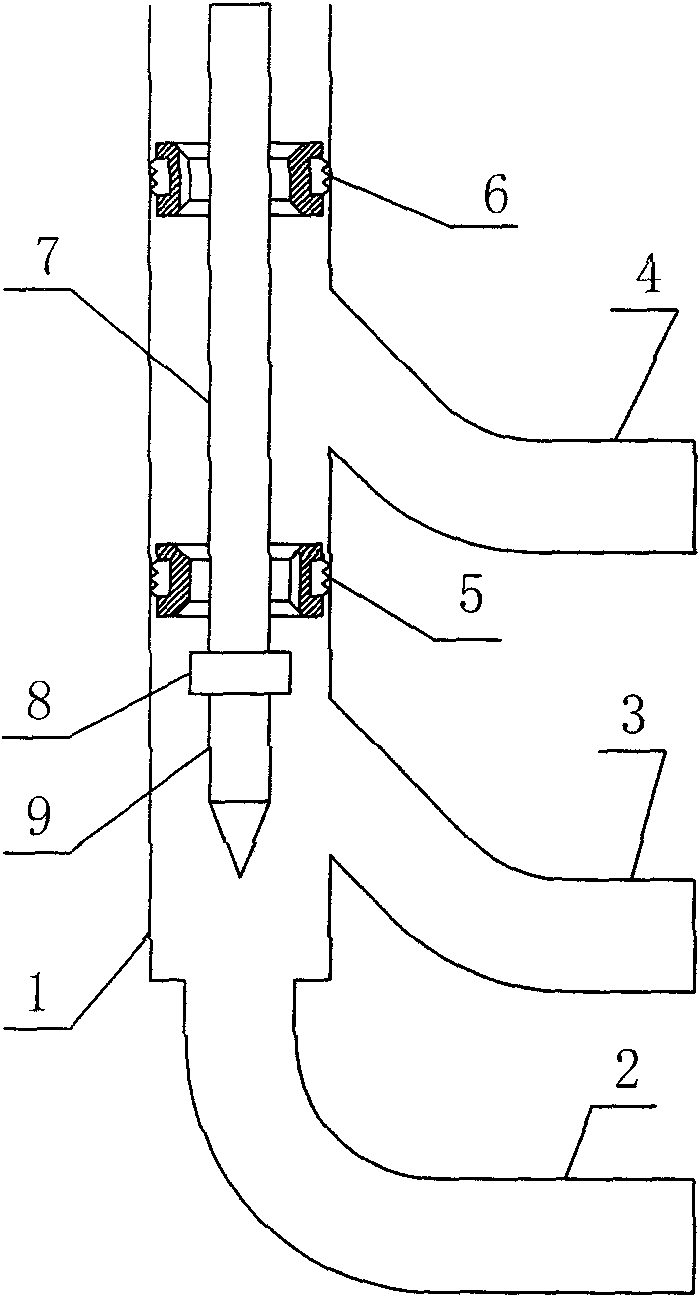

[0028] (2) Pipe string re-entry of main branch 2: the post-operation pipe string 7, centralizer 8 and guide head 9 are connected in sequence to form the main branch re-entry pipe string. The center of t...

Embodiment 2

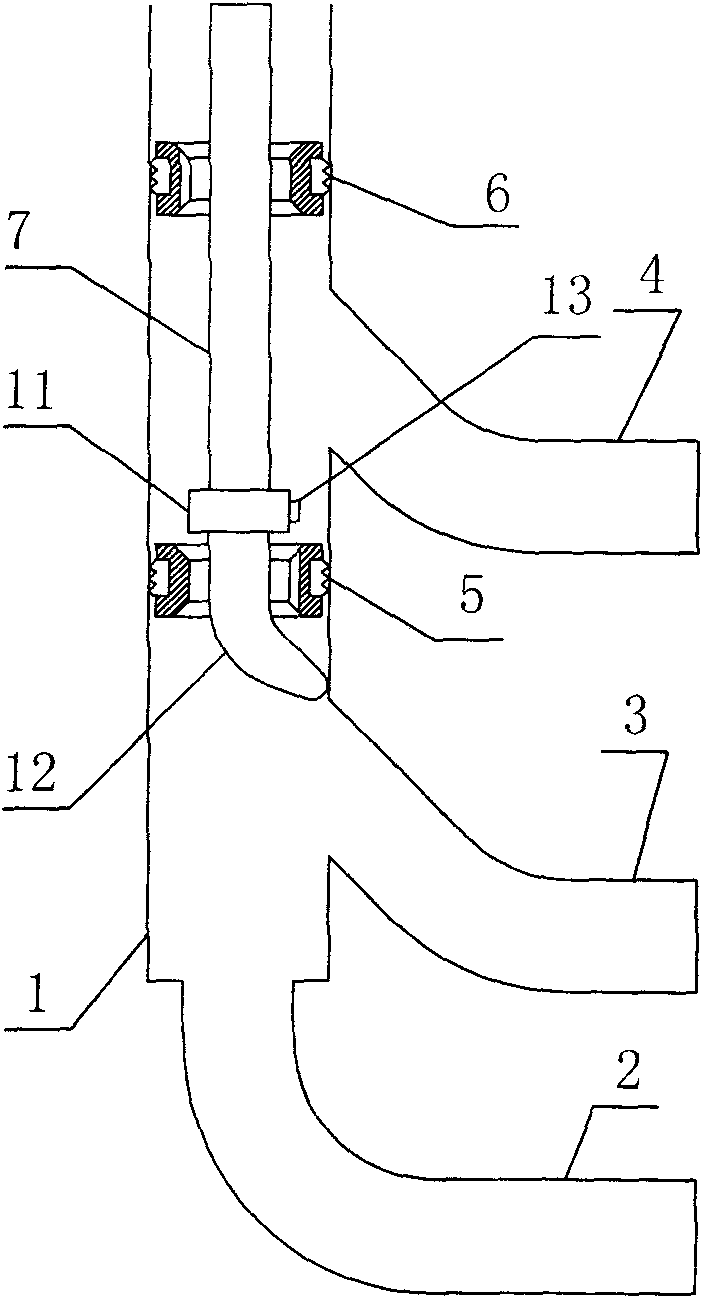

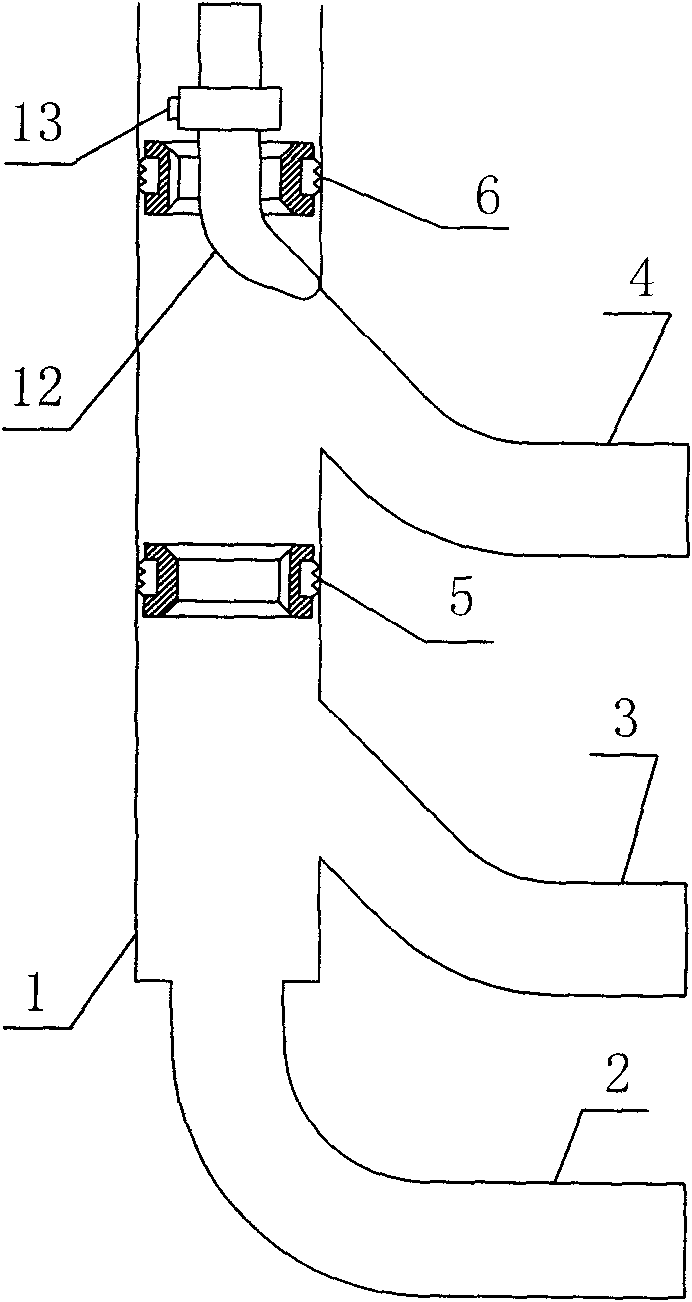

[0031] Refer to the attached Figure 1-3 , the present invention discloses a method for re-entrying a multi-branched post-operation pipe string, the steps of which are as follows: (1) For a branched well with three branches, during or after drilling and completion, in the main wellbore 11 Run the guide sleeve 1 5 and the guide sleeve 2 6 with the delivery pipe string, and anchor them above the windows of the side branch 1 3 and the side branch 2 4 respectively;

[0032] (2) String reentry of the main branch 2: the reentry string of the main branch is lowered, and the pointed straight guide head 9 goes down along the center of the main wellbore 1 under the support of the centralizer 8 to guide the later operation string 7 Enter the wellbore of the main branch 2;

[0033] (3) Pipe string reentry of side branch one 3: run down side branch one reentry pipe string, when the guide key 13 of the guide joint 11 passes through the guide groove of the guide sleeve, the elbow of the gui...

Embodiment 3

[0036]If there are more branches, the corresponding guide sleeve is also anchored above the branch window. The wellbore leading angle and the pipe string leading angle of the side branch are uniformly distributed within 360 degrees. For example, in a 4-branch well, the wellbore leading angle and the pipe string leading angle of the side branch 1 are 0 degrees, and the wellbore of the side branch 2 4 The steering angle and pipe string steering angle are 120 degrees, and the borehole steering angle and pipe string steering angle of side branch 3 are 240 degrees, which can realize the selective entry of the later operation string 7 of the 4-branch well.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com