Automatic Detection Method of Cogging Torque of Permanent Magnet Synchronous Motor

A permanent magnet synchronization and cogging torque technology, applied in the detection field, can solve the problems of complex installation, inability to continuously detect, and low accuracy of manual detection of cogging torque, and achieve the effect of easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creation features, achievement goals and effects of the present invention easy to understand and understand, the present invention will be further described below with reference to the specific drawings.

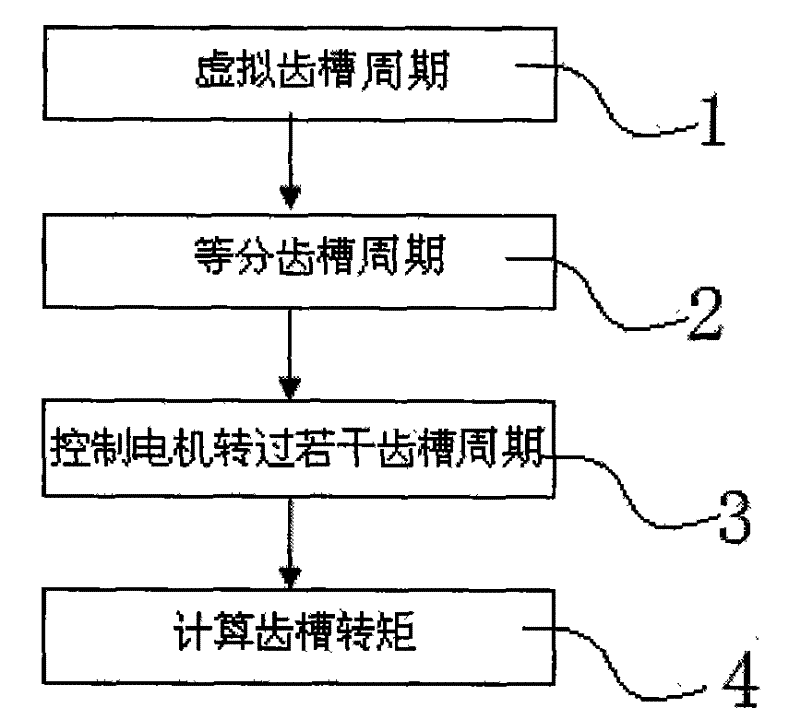

[0029] According to the cause of the cogging torque, it can be known that the cogging torque changes periodically with the rotor position of the motor. Therefore, using a frequency converter to drive a permanent magnet synchronous motor can detect the output torque of the frequency converter when the rotor position changes, and then calculate The cogging torque of the permanent magnet synchronous motor to be tested can be obtained.

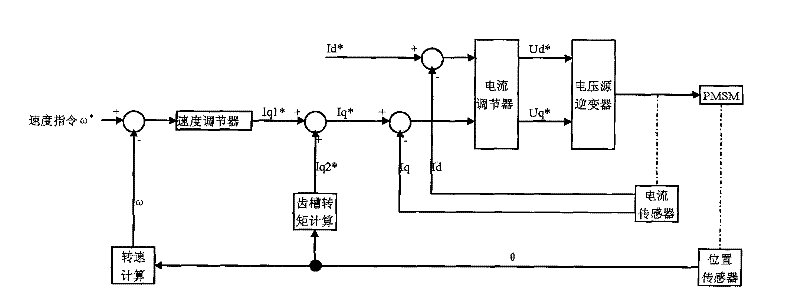

[0030] The present invention is based on the implementation of the inverter-driven permanent magnet synchronous motor system such as figure 1 As shown, in the control loop of the inverter, the inverter uses the position signal and speed command sent by the position sensor to control the operation of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com