Device for rotating and holding a winding tube and home automation equipment including such device

A technology for home automation and coiling, which can be used in door/window protection devices, windows/doors, building components, etc., and can solve problems such as impossible to adjust coils.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention can be used for various types of scrolling screens. The uses described below correspond to one type of screen, the roller blind. Of course, this example is non-limitative and the invention can also be applied to any other type of screen, in particular blinds.

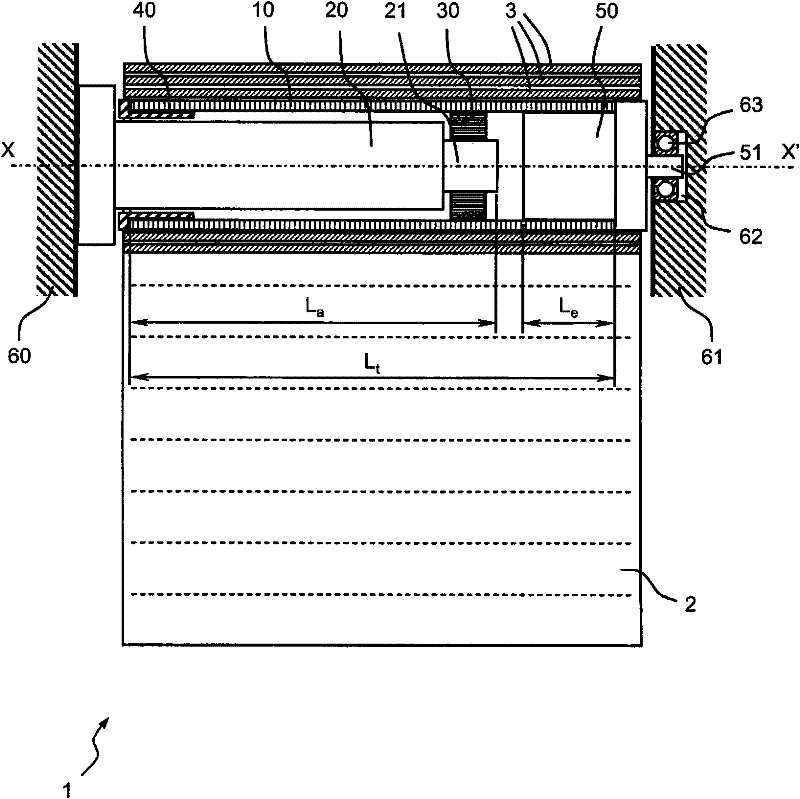

[0029] figure 1 A motor-driven roller blind 1 of known assembly (method) is shown. The slats 3 of the baffle 2 are rolled around the tube 10 . The tube is driven in rotation by a tubular actuator 20 fastened to a frame 60 . A tubular actuator generally comprises a tube into which a gear motor is inserted at one end and a control module inserted into the other end of the tube for controlling the power supply to the gear motor. The gear motor terminates in an output shaft protruding from the tube of the actuator. The output shaft 21 of the actuator transmits the drive torque to a drive wheel 30 fixed to the tube. In order for the tube to rotate about its axis XX', the tube is guided in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com