Reel seat

A technology of fishing reel seat and fishing reel, which is applied in fishing, application, fishing rod, etc., and can solve the problems of lower quality of fishing reel seat and poor feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach 〕

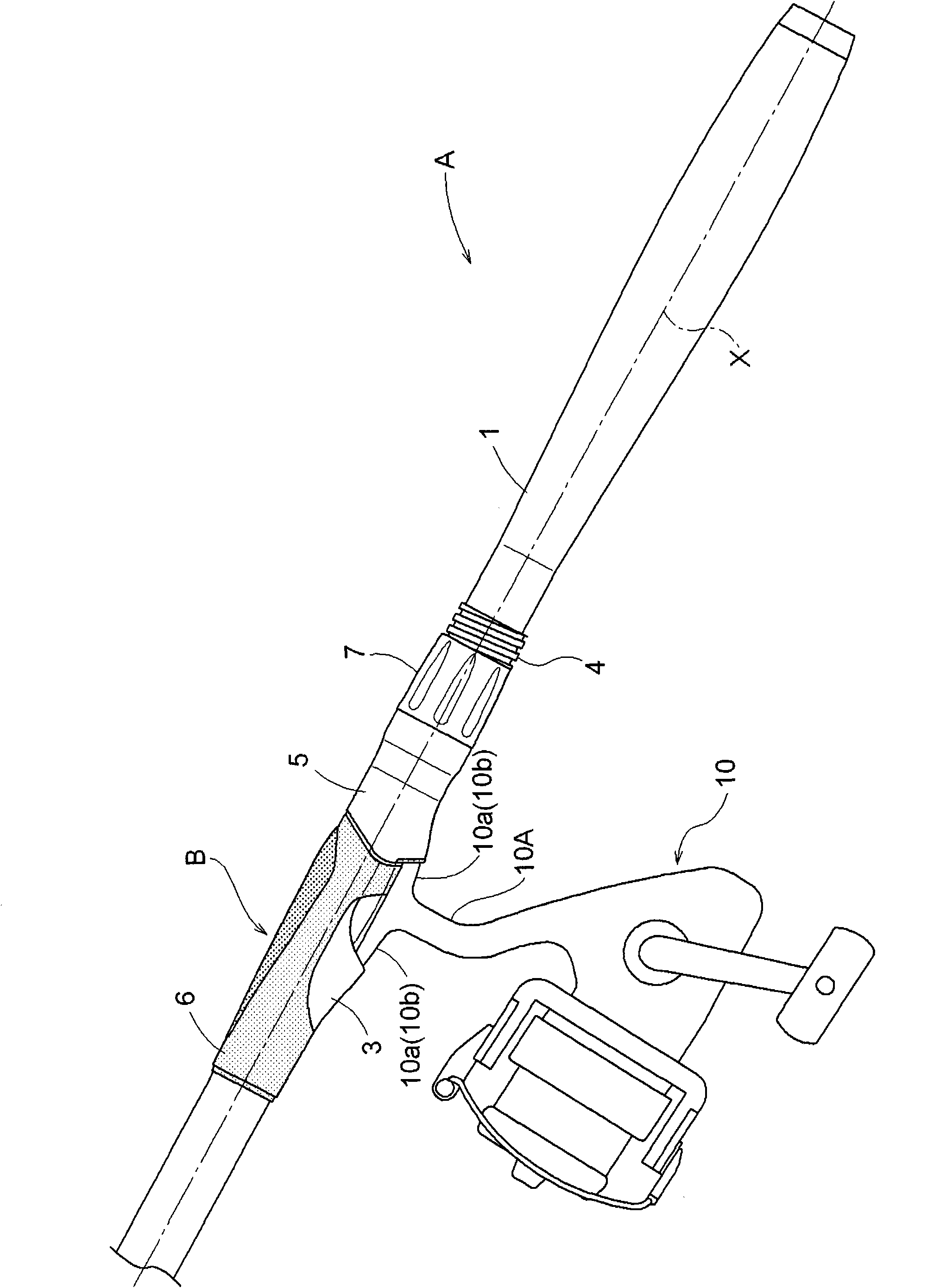

[0043] Next, an embodiment in which the present invention is applied to the fishing rod A will be described.

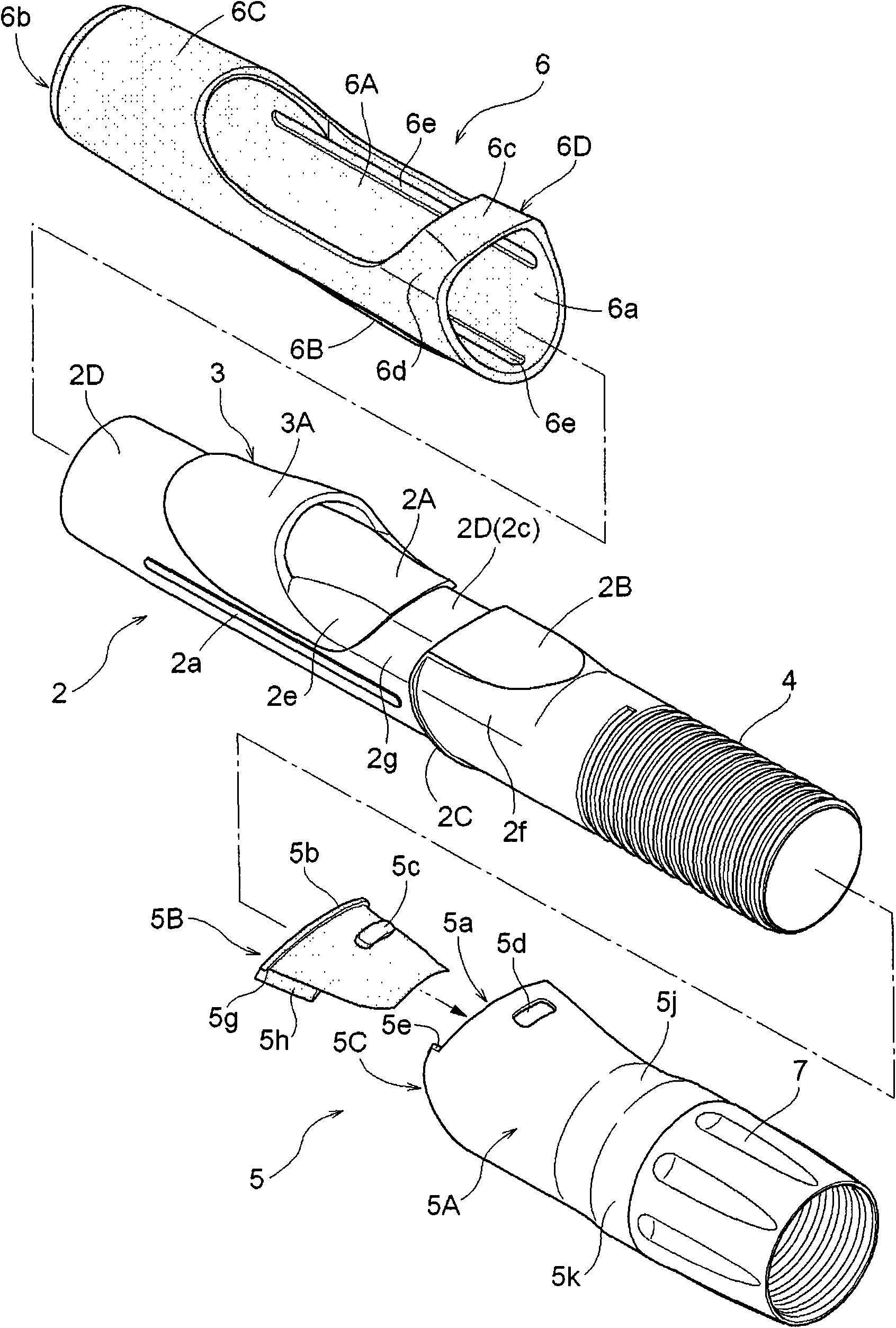

[0044] Such as Figure 1~4 As shown, the fishing rod A is configured such that a cylindrical fishing reel seat B for mounting a reel 10 is mounted on the tail rod 1 as a rod body having a grip portion, and the seat of the cylindrical fishing reel seat B A movable cover 5 is mounted on the base 2 .

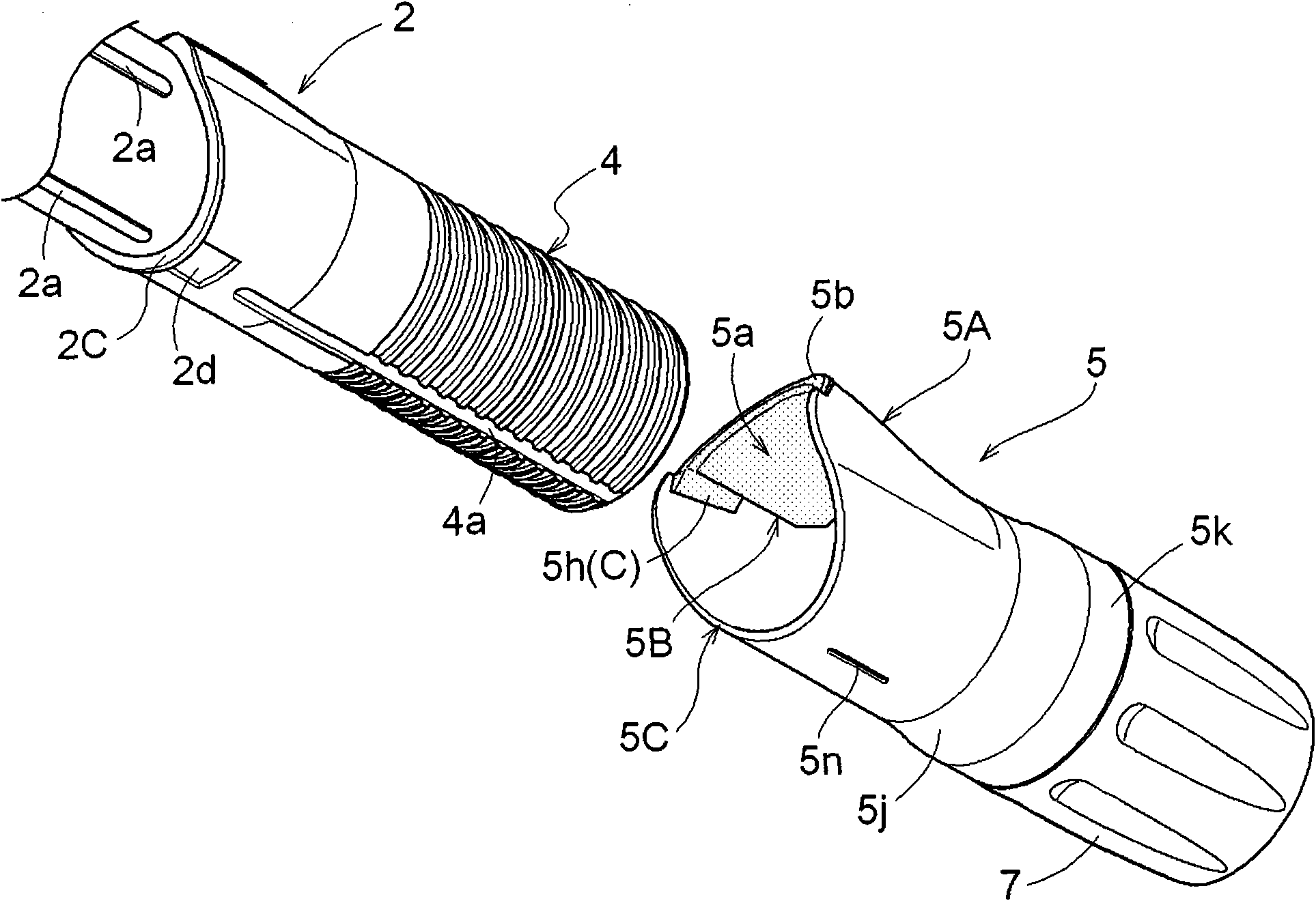

[0045] A fixed cover 3 is integrally formed on the seat base 2, and the fixed cover 3 cooperates with the movable cover 5 to support the front leg portion 10a formed by bending the top end of the reel leg 10A of the reel 10 toward the rod tip side. For holding, the internal thread portion 4 to which the movable cover 5 is screwed is provided on the rear side of the portion where the fixed cover 3 is formed.

[0046] Such as Figure 4 , Figure 8 with Figure 9 As shown, the movable cover 5 is equipped with a cover main body 5A, a leg pressing body 5B, and a nut body 7...

no. 2 approach 〕

[0098] In the first embodiment, an embodiment in which the annular flange 2C is not formed on the base portion 2 is defined as a second embodiment. Therefore, there is no state where the portion of the annular flange 2C is flush with the other outer peripheral surface of the base portion 2 .

no. 3 approach 〕

[0100] In the first embodiment, an embodiment in which the rubber grip 6 is not attached to the seat base 2 is defined as a third embodiment. Therefore, there is no mounting seat 2D for attaching the rubber grip 6 formed on the base 2 , and the outer surface of the base 2 is formed flush with the outer surface of the fixed cover 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com