Semiconductor grain point measurement machine test method and semiconductor grain point measurement machine

An inspection method and semiconductor technology, which is applied in semiconductor devices, semiconductor/solid-state device testing/measurement, semiconductor/solid-state device manufacturing, etc., can solve problems such as misjudgment of grain detection and plummeting worth, so as to avoid a large number of false detection grains Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

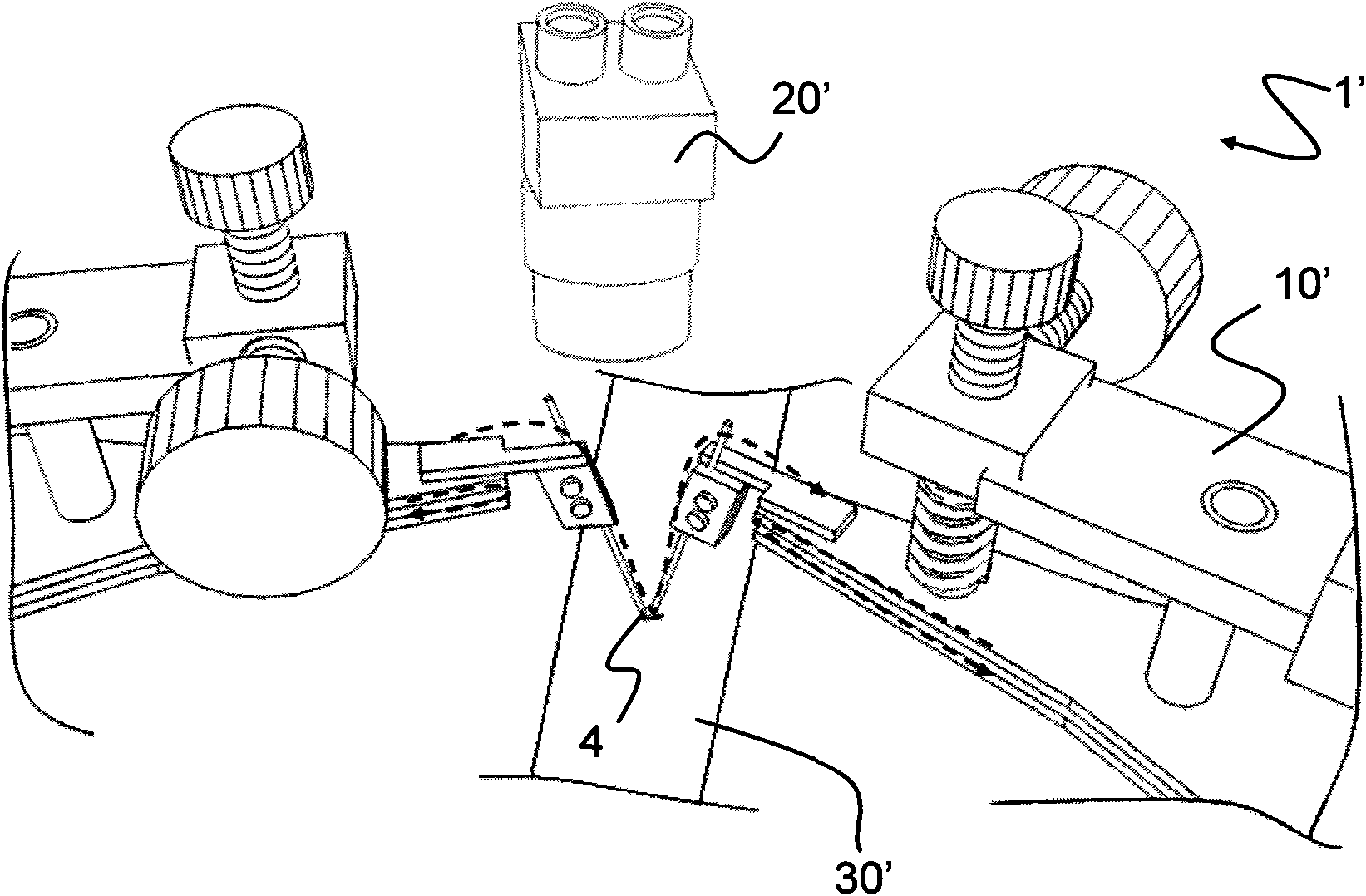

[0033] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of preferred embodiments with accompanying drawings. For the convenience of description, the machine inspection method of the present invention is taken as an example of a spot test machine for semiconductor grains for optical inspection, and the control unit and support lines necessary for the base of the machine are omitted to avoid confusion in the drawing.

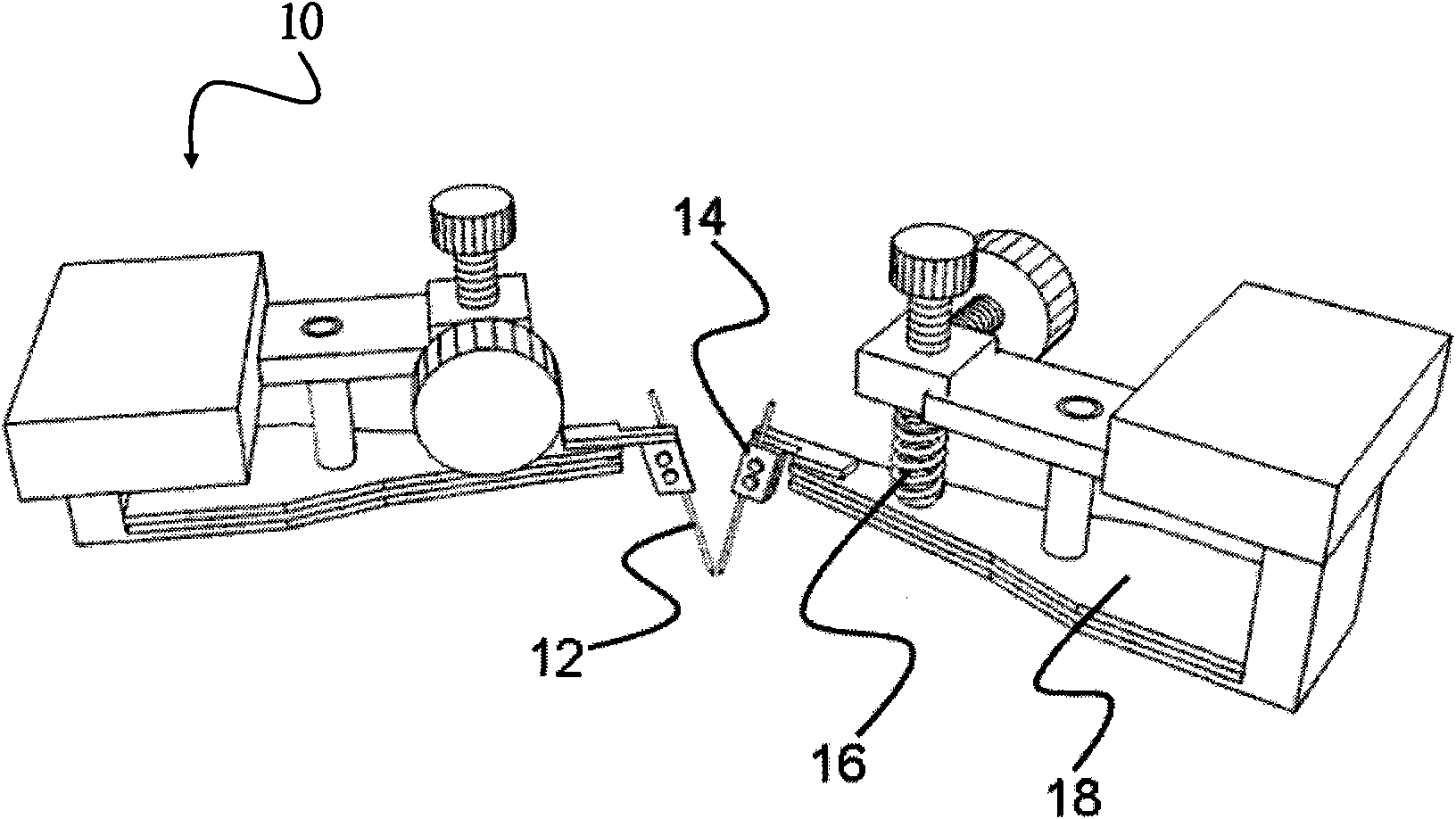

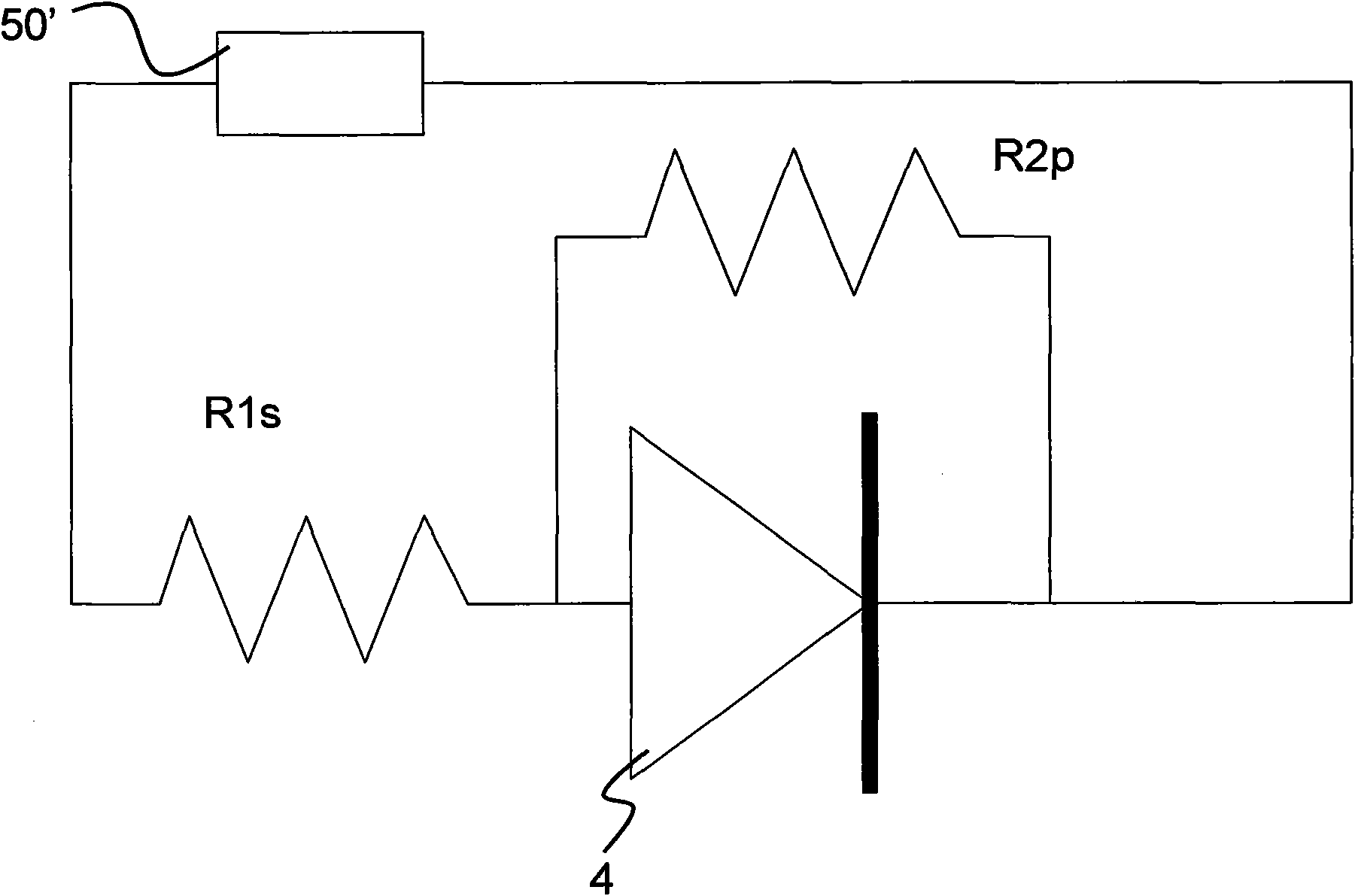

[0034] Such as figure 2 As shown, this is a schematic diagram of the simulated circuit of the grain to be tested. In this figure, the inherent minute resistance of the conductive circuit is represented by R1s, and the resistance of the insulating part used to isolate the circuit system from the rest of the components is represented by R2p. And when using the above-mentioned common structure detection, such as image 3 As shown, two groups of edge sensor...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap