Efficient adaptive method for mathematical model of aluminum cold rolling mill

A technology of mathematical model and self-adaptive algorithm, applied in the direction of self-adaptive control, instrument, control/regulation system, etc., can solve the problems of low calculation precision of rolling parameters, few mathematical models, poor precision, etc., to improve the preset Control accuracy and product quality, strong practicability, and the effect of improving self-adaptive accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

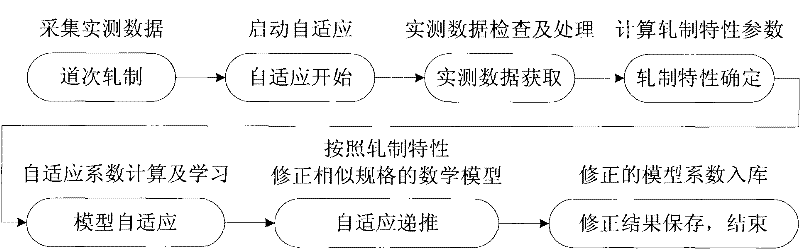

[0025] The invention proposes an efficient self-adaptive method for the mathematical model of an aluminum cold rolling mill, figure 1 It is a schematic diagram of the implementation process of this method, and the specific detailed steps are:

[0026] (1) During the pass rolling process, the measured data of each rolling parameter is collected and stored for subsequent mathematical model self-adaptation;

[0027] (2) The pass rolling ends, and the mathematical model self-adaptation is started;

[0028] (3) Acquisition of measured data, according to the status of the rolling process, limit checking and exception handling are performed on the measured data of the rolling process of this pass;

[0029] (4) Calculation of rolling characteristic parameters, according to specification data such as material, deformation resistance, width, entrance thickness, exit thickness, annealing thickness, etc., calculate the rolling characteristic parameters of this pass;

[0030] (5) After t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com