Processes and Device for Low Temperature Separation of Air

A technology for separating air and low temperature, applied in lighting and heating equipment, cold treatment separation, refrigeration and liquefaction, etc., can solve problems such as turbine damage, and achieve the effect of low equipment cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

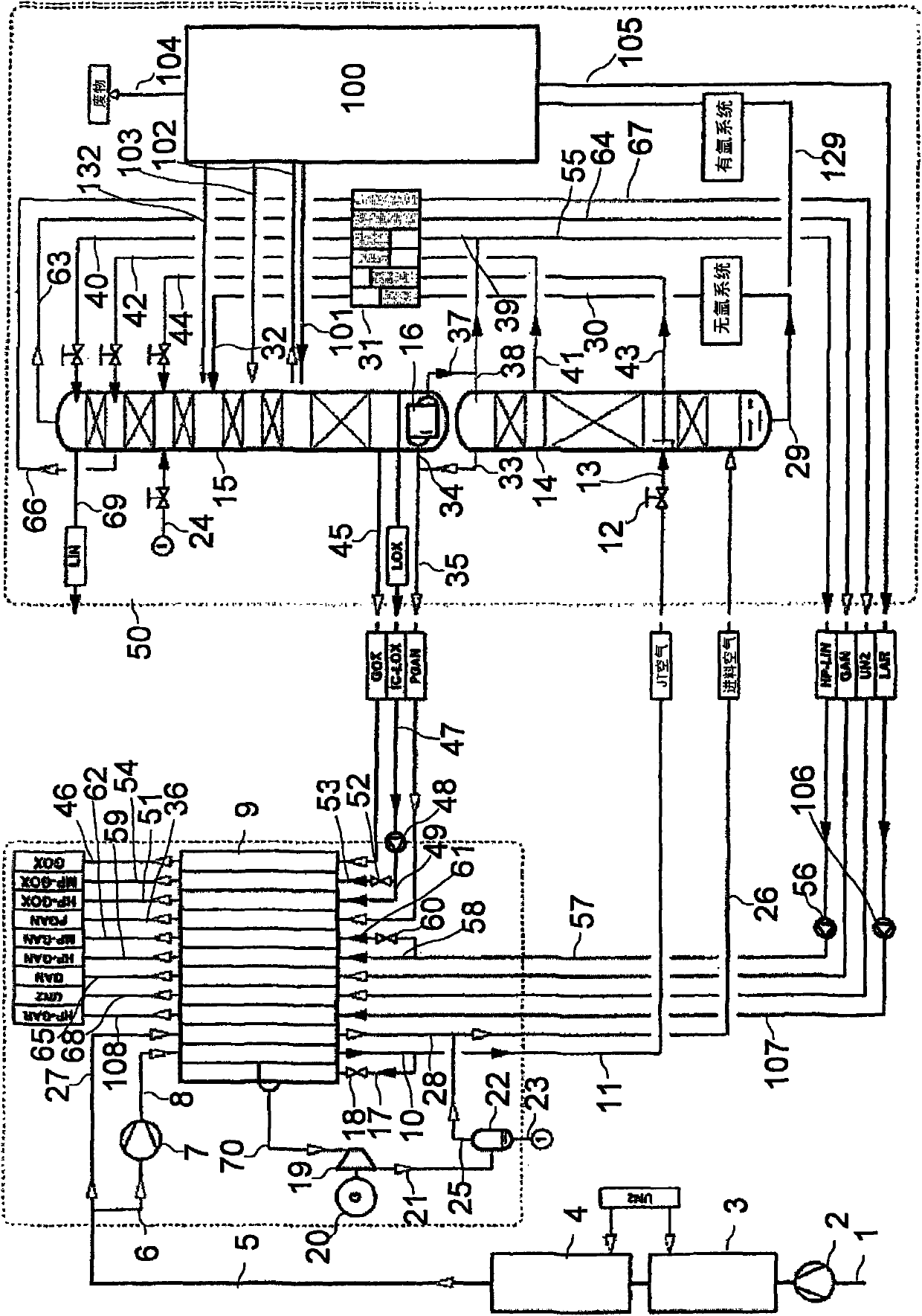

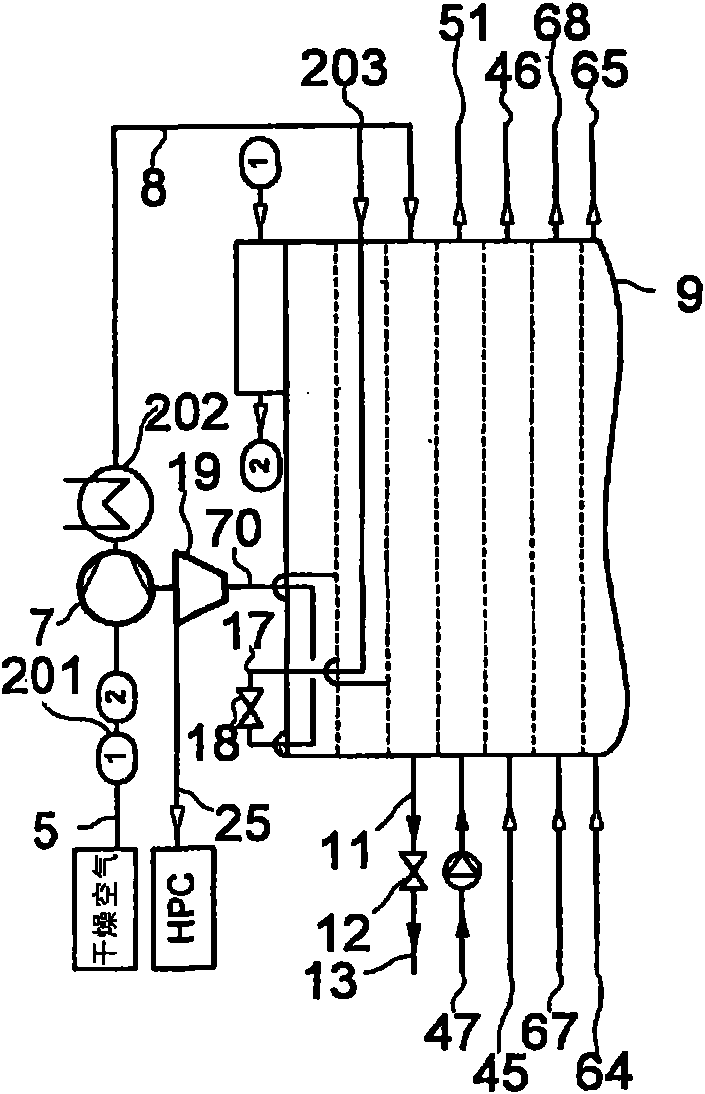

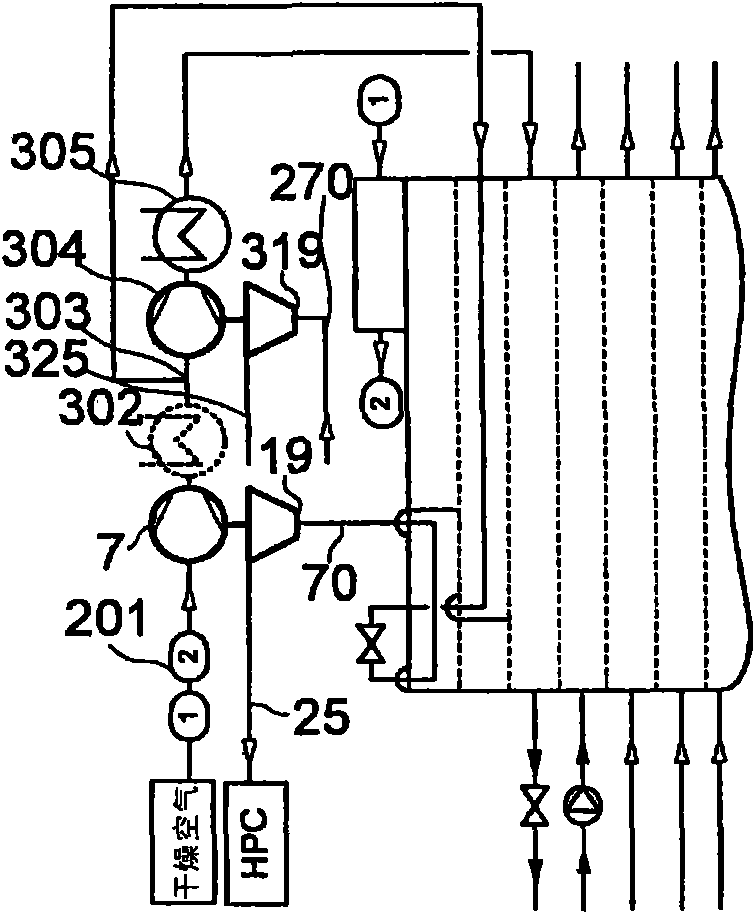

[0029] exist figure 1 In the embodiment of the present invention, the distillation column system 50 has a high-pressure column 14, a low-pressure column 15 and a main condenser 16 configured as a condenser-evaporator in the part for the separation of nitrogen and oxygen, and the two columns pass through the main condenser form a heat exchange relationship.

[0030] Atmospheric air is sucked in as the main air flow via line 1 by an air compressor 2, raised there to a first pressure substantially equal to the operating pressure of the high-pressure column 14, cooled in a precooler 3 to approximately ambient temperature and Supply to an adsorption air cleaning device 4. A first part of the cleaned main air flow 5 is recompressed in a recompressor 7 to a second pressure of at least 50 bar, for example approximately 60 bar, as "first air flow 6". The high pressure air 8 is led to the hot end of the main heat exchanger 9 where it is cooled and pseudo-liquefied. The pseudo-liquefi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com