Double screw nut gap eliminating device

A technology of silk nut and anti-backlash, applied in the field of machine tools, can solve problems such as poor positioning accuracy, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so as to help understand the content of the present invention.

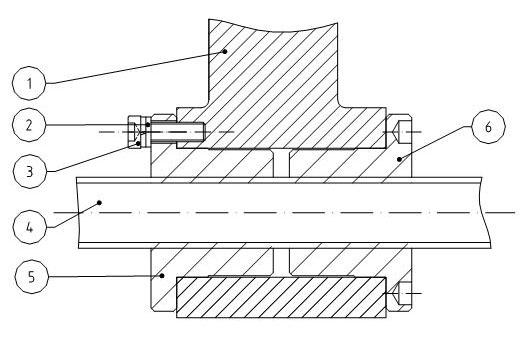

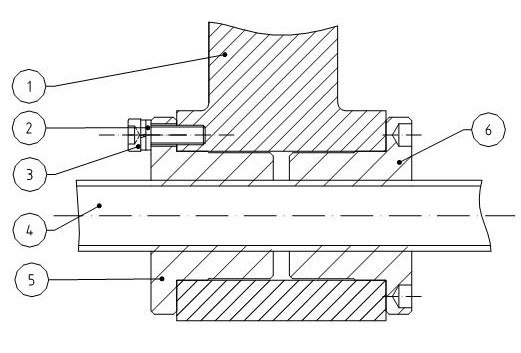

[0012] Such as figure 1 As shown, the present invention fixes the left screw nut 5 on the left end of the bracket 1 with the hexagon socket head cap screw 3 and the anti-loosening washer 2, connects the screw rod 4 with the left screw nut 5, then connects the right screw nut 6 with the screw rod 4, adjusts The right screw nut 6, so that the screw rod 4 has no axial clearance and can rotate freely. Use another hexagon socket head cap screw and a lock washer to fix the right screw nut 6 on the right end of the bracket 1. At this time, the left end surface of the left screw nut 5 thread and The right end face of the screw thread 4 is in contact with the right end face of the thread of the right screw nut 6 and the left end face of the thread of the screw rod 4, that is, the left and ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com