Mechanical cross screw rod supporting device

A technology of mechanical support and transverse screw, applied in the field of machine tools, can solve problems such as large sag deflection, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

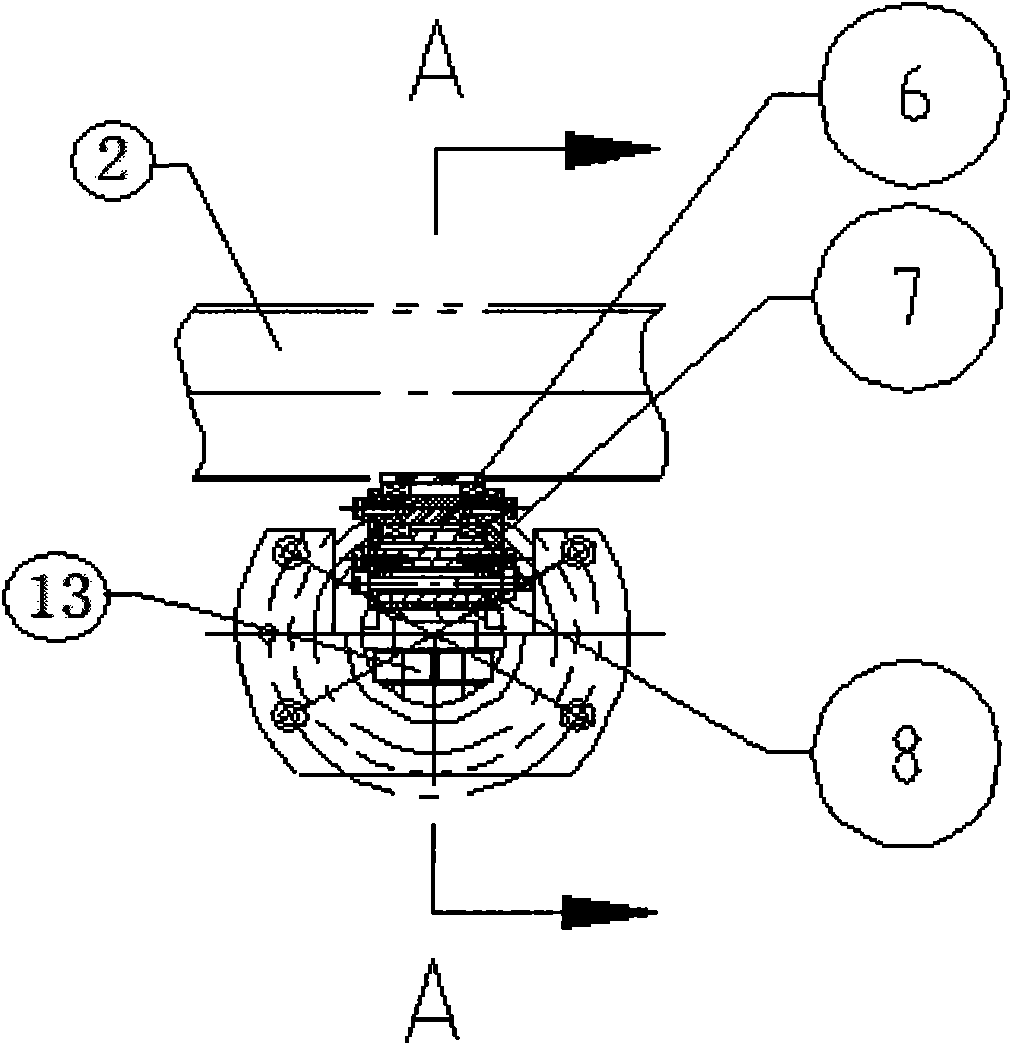

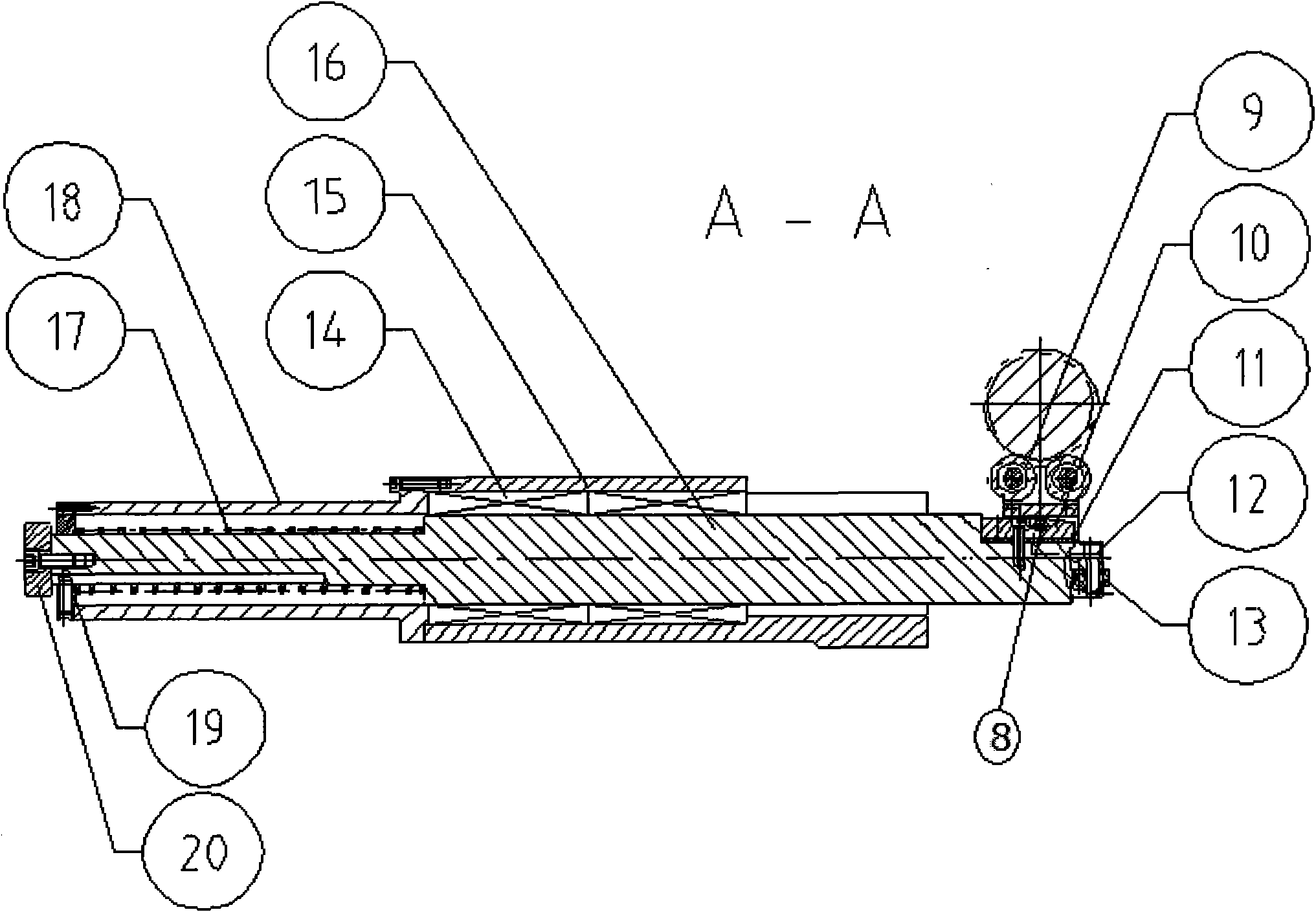

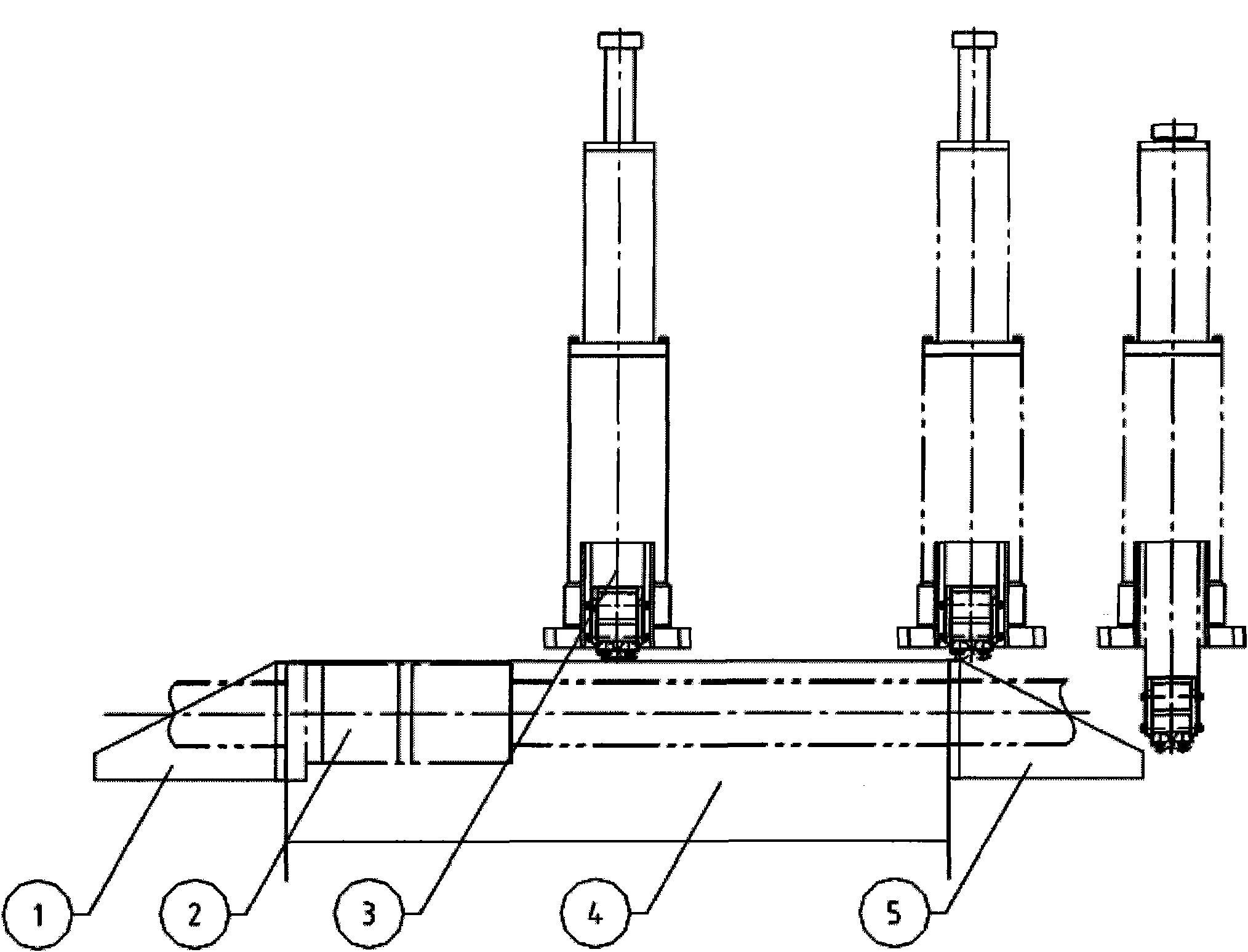

[0013] image 3 As shown, the horizontal screw mechanical support device 3 of the present invention is installed at the middle position of the horizontal screw rod 2. When the horizontal sliding plate 4 is on the left side of the horizontal screw mechanical support device 3, the horizontal sliding plate 4 moves to the right and approaches the horizontal screw. When the rod mechanical support device 3 is used, the right bracket 5 of the skateboard first presses the bearing roller 13, and the force is transmitted to the extension shaft 16 through the pin shaft 12, so that the extension shaft 16 overcomes the force of the spring 17 and drives the screw support wheel 9 to retract , let the horizontal slide plate 4 pass through the top of the horizontal screw mechanical support device 3, the horizontal slide plate 4 continues to move to the right, the left bracket 1 of the slide plate and the bearing roller 13 have a pressing effect, and during the movement of the horizontal slide p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com