Closing-in device of joint bearing with spherical surface

A technology of joint bearing and mouthpiece, which is applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of large assembly volume, bearing joints, and inability to bear joints, and achieve the effect of accurate joint positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

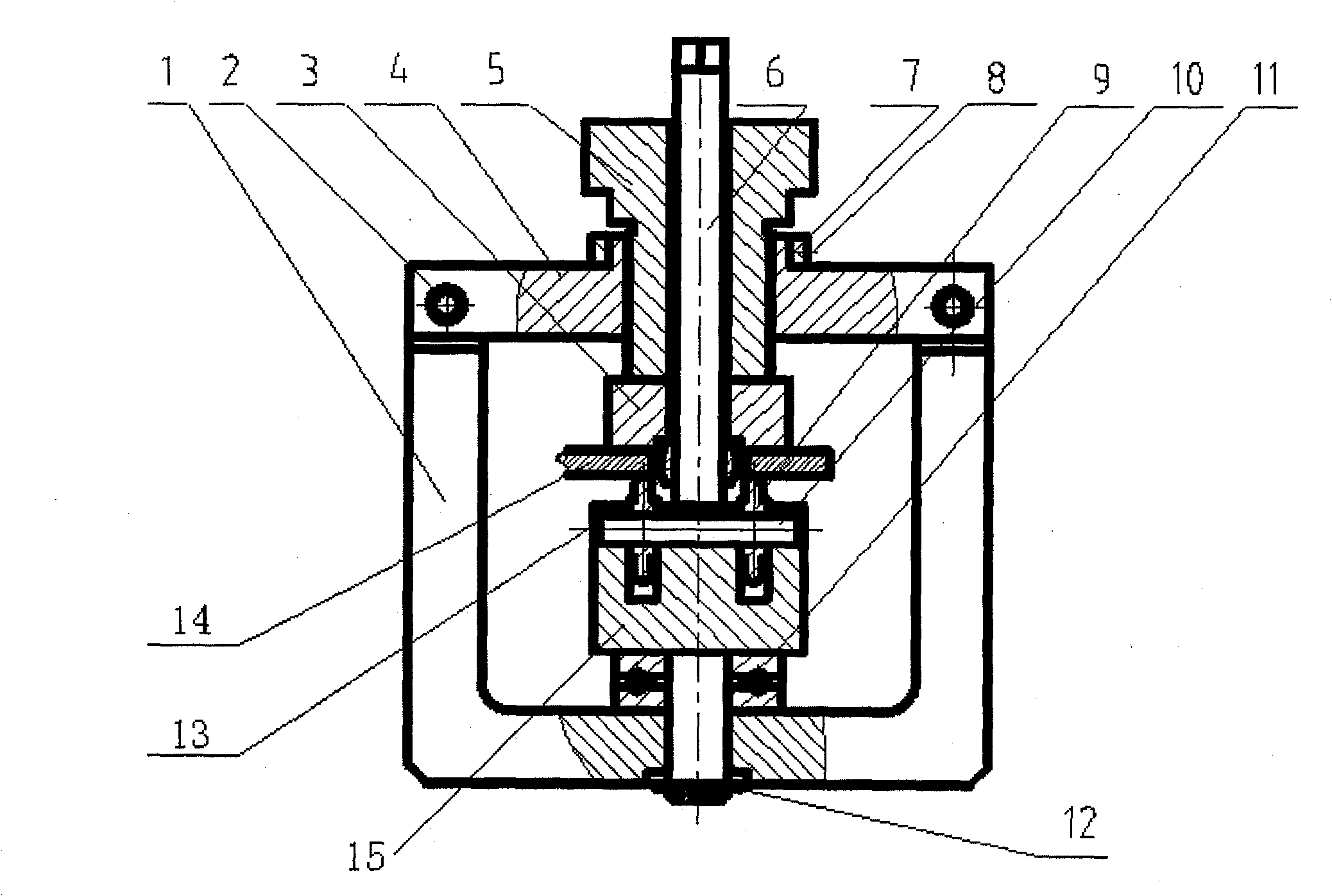

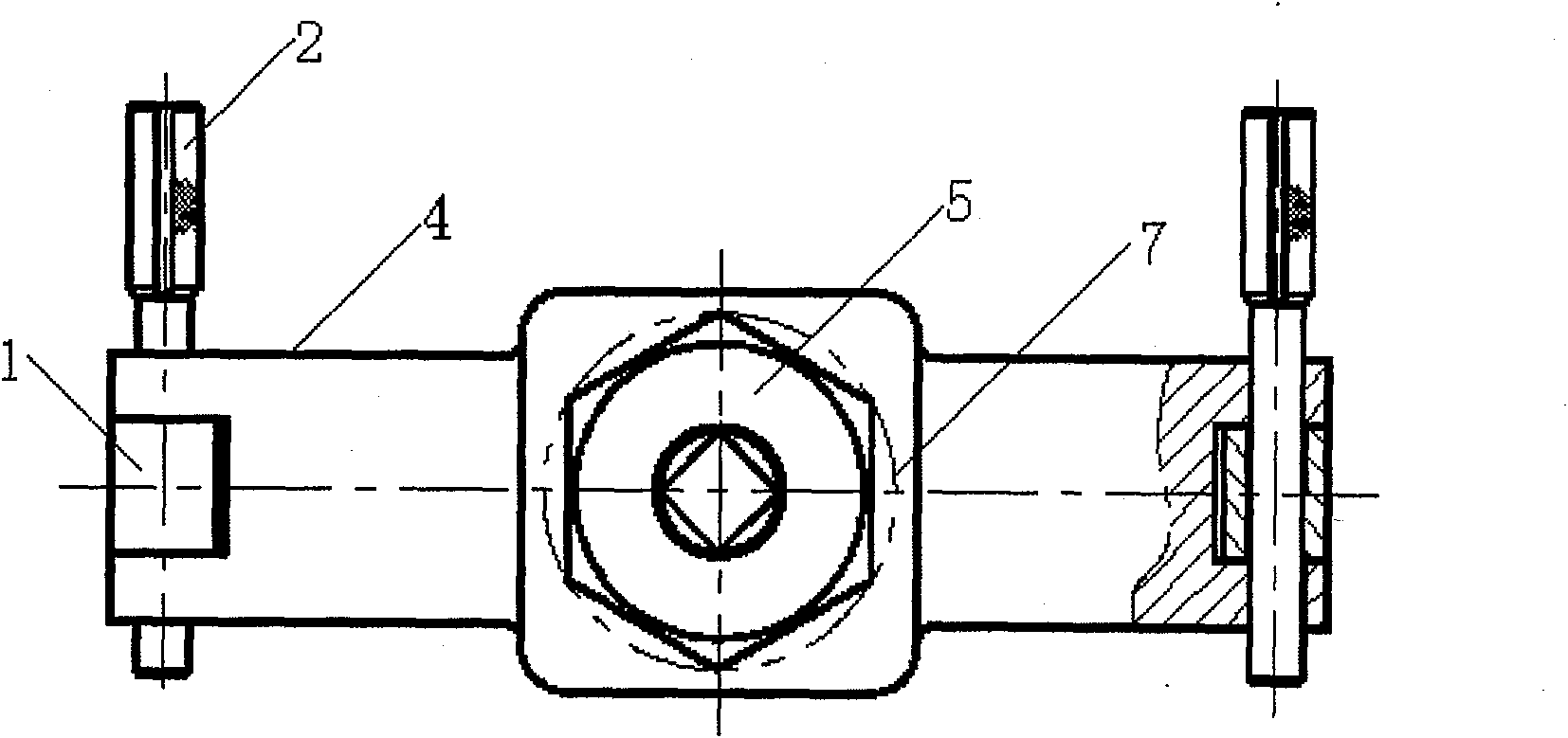

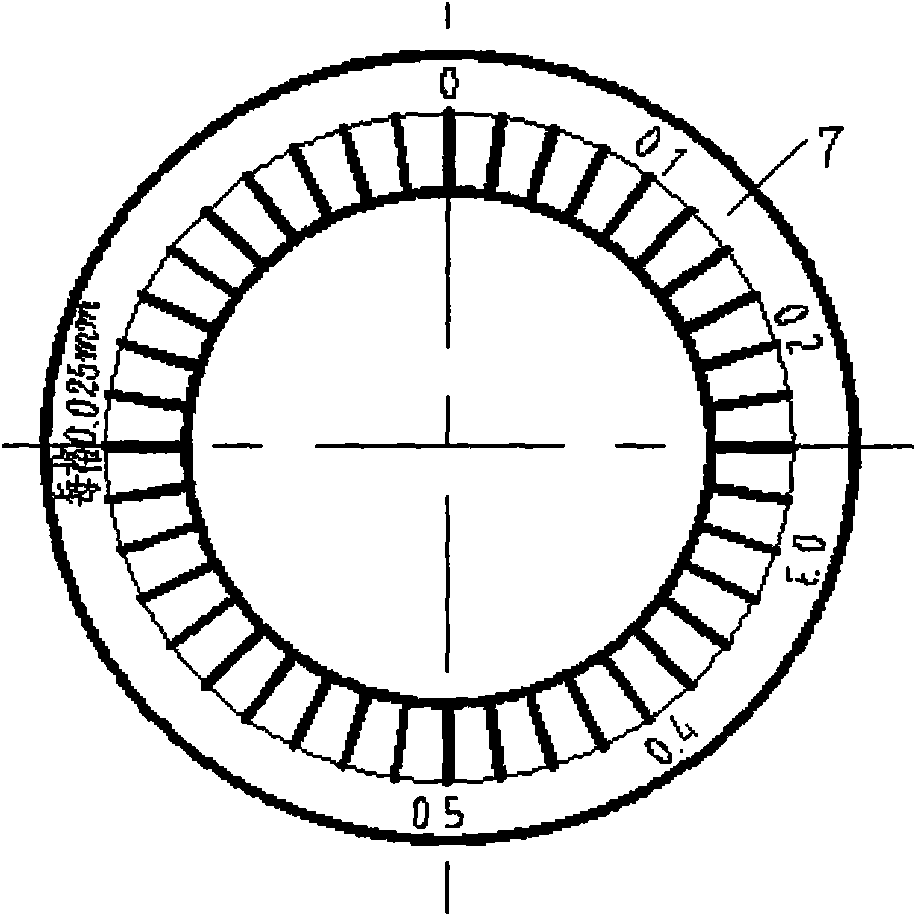

[0013] exist figure 1 , figure 2 In the best embodiment of a spherical joint bearing mouthpiece shown, in figure 1 , figure 2 In the best embodiment of a spherical joint bearing mouthpiece shown, there is a pressing plate 4 connected by a pin 2 on the frame opening of the base 1 in the shape of a rectangular frame, and the pressing plate 4 is fixedly connected to the frame opening at the upper end of the rectangular frame groove of the base 1 . It constitutes the base frame of the bearing mouthpiece of the present invention. The upper and lower ends of the base frame are provided with closing-shaped surface pressing plates 3 and double-acting rollers 9 that act oppositely on the closing surface of the bearing. The closing surface pressing plate 3 is shaped on a groove consistent with the shape of the bearing closing surface, and it fits on the bearing closing surface from top to bottom through the spinning bolt 5 connected to its upper end. The pressure plate 4 is shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com